Mazda has always been distinguished by non-standard design solutions. She was the only one for a long time mass-produced machines with rotary engines. And when the next stage of improving the usual piston engines came, she again went her own way.

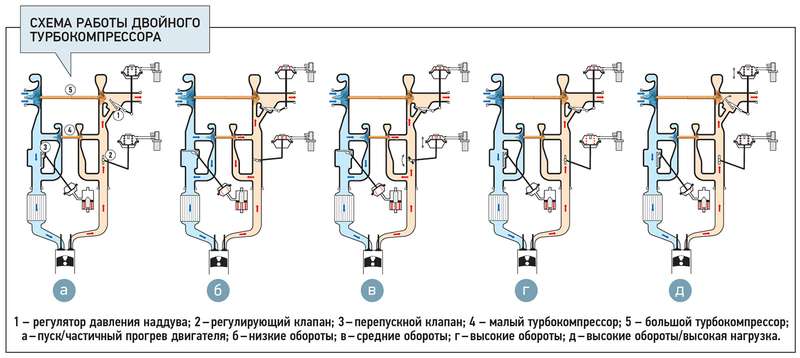

Engineers of all companies now face one task: to simultaneously increase the efficiency and efficiency of engines by inscribing them into the stringent Euro-6 environmental standards. The recipe of European engineers is low-volume supercharged engines.

Mazda rejected the idea of downsizing - they say, all these superchargers, intercoolers, pipelines are too expensive, and there is little joy from small-capacity engines. And again I decided to go my own, purely Japanese way - to keep the "full-size" aspirated, but play with the compression ratio (SJ).

So a new family of engines was born - Skyactiv. Two first-borns settled on the CX‑5 crossover: a two-liter gasoline engine and a 2.2-liter turbodiesel. Both have the same compression ratio - 14. This is a lot for a gasoline engine (usually 10-12) and very low for a diesel engine (usually 16-18.5).

The compression ratio is the ratio of the volume of space above the piston at its bottom dead center (cylinder and combustion chamber volume) to the volume of space above it at its top dead center (combustion chamber volume). The compression ratio shows how many times the air-fuel mixture is compressed in the cylinder. The thermal efficiency of the engine and its power depend on this parameter.

When building the petrol aspirated Skyactiv-G , the predecessor MZR 2.0 with a compression ratio of 10.0 was taken as the basis. An increase in coolant increases the temperature and pressure in the cylinder at the end of the compression stroke. This promises higher efficiency and power, but at the same time a strong tendency to detonation - the explosive combustion of the air-fuel mixture, which leads to overheating and destruction of rings and pistons. A coolant close to 14 is more typical for highly accelerated sports engines running on high-octane fuel that is resistant to detonation. A lot of innovations have been made to the Skyactiv-G design so that it can painlessly digest regular 95 gasoline and work on reducing mechanical losses in order to improve efficiency.

Ion sensors built into the ignition coils are designed to protect the engine from detonation. The whole point is that the operation of the motor is on the verge of detonation and ensures the most efficient combustion of the mixture . Ionic sensors are more sensitive and allow better control of the moment of detonation in each cylinder - and before that it was monitored by only one traditional guard installed in the block. The new sensor monitors detonation by fluctuations in the ion current in the gap between the spark plug electrodes after the mixture has ignited. When it burns, ions are formed that make the medium conductive. The sensor applies voltage to the center electrode of the spark plug and measures the current flowing between it and the grounded side electrode.

The updated fuel system with direct injection provides pressure up to 200 bar! With an increase in pressure in the cylinder, this became necessary for proper mixture formation (previously, Mazda used direct injection mainly for supercharged engines, but the pressure did not exceed 115 bar). At the output, this solution provides efficient combustion, that is, high power, efficiency and environmental friendliness of the engine.

As before, the injection pump (high pressure fuel pump) is driven by a camshaft, but this time from the exhaust. It is complemented by six-hole nozzles (for better fuel atomization). With good evaporation, gasoline also brings down the temperature in the combustion chamber, and this also reduces the likelihood of detonation.

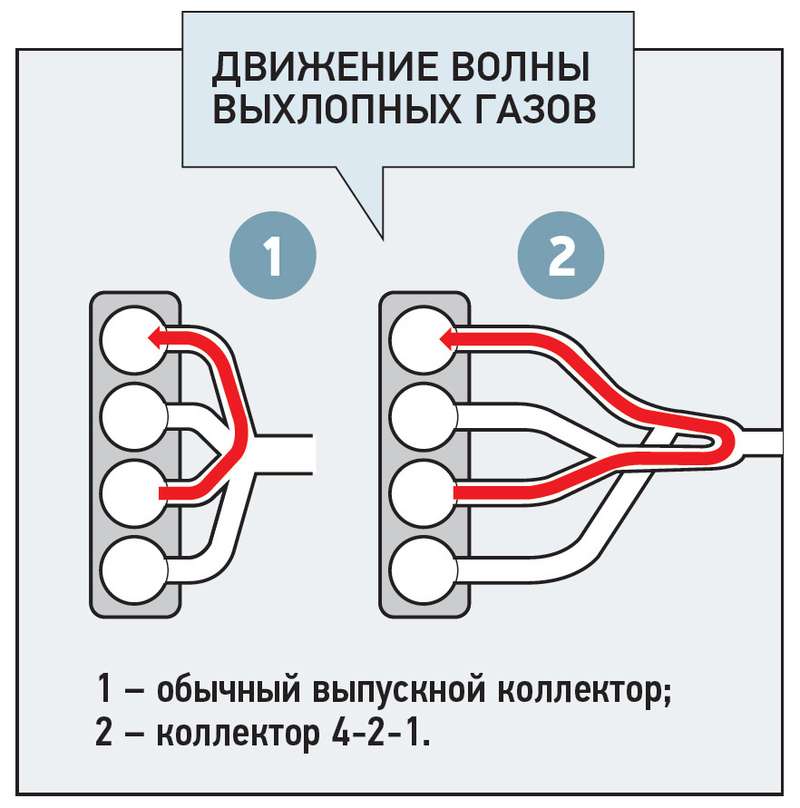

The exhaust system is equipped with a 4-2-1 manifold that came from motorsport. Its configuration reduces resistance as exhaust gases (EG) exit the cylinders. In a conventional manifold, the exhaust gas wave from one cylinder may coincide with the opening of the exhaust valves in the next one. It creates a back pressure that prevents the next portion of the exhaust gases from escaping.

The design of the "sports" manifold has a different pipe connection scheme, in addition, they are longer. Because of this, the exhaust gas flow travels a greater distance and, on the contrary, creates a rarefaction wave, which facilitates the exit of gases from the next cylinder. In addition to increasing engine power, this reduces the temperature in the combustion chamber, also reducing the likelihood of detonation.

To reduce pumping losses in the motor and increase efficiency, engineers taught him to work in two cycles: Atkinson and the more traditional Otto cycle for gasoline engines. The first is activated at low loads, when there is no need for high torque: the intake valves close later, already on the compression stroke, and part of the air exits through them back into the intake manifold. Essentially, the piston travels part of the way without compressing the air. This reduces the actual coolant and torque, but also the pumping losses. In this mode, the motor runs more efficiently.

And at medium and high loads, the intake valves close earlier (the usual Otto cycle) and the cylinders are completely filled. SJ again reaches 14 - and the motor produces high torque.

The Atkinson cycle forced engineers to include a vacuum pump in the intake system to keep the brake booster working properly. And all because of the lack of vacuum in the intake manifold when the engine is running in this mode. The pump is driven by the exhaust camshaft and shares the housing with the injection pump.

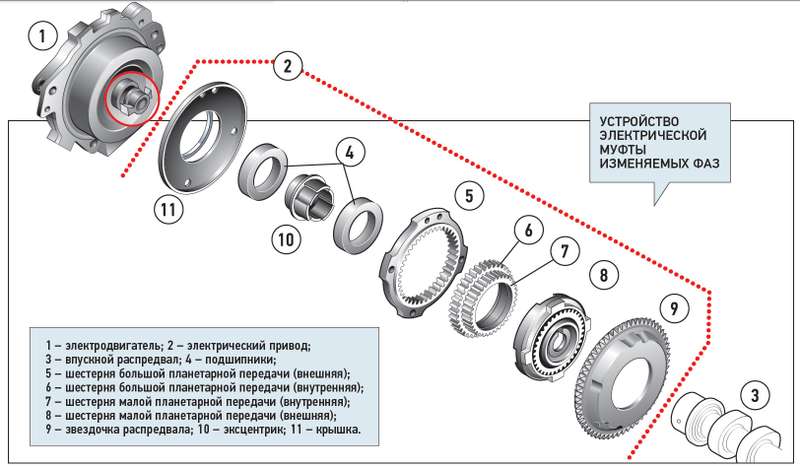

Previously, similar but simpler components were common only for supercharged engines - they generally have trouble with vacuum. The engine is able to work in two cycles thanks to two variable phase clutches - this is the usual hydraulic on the exhaust camshaft and electric on the intake.

The electric clutch is more efficient, but it has not been used on Mazda engines before. It has a larger control range and provides more precise control compared to hydraulic. The clutch consists of an electric motor (installed on the front cover of the motor) and a drive connected to it (fixed on the camshaft itself), which is an intricate planetary gear. As long as the speeds of rotation of the electric motor and the camshaft are equal, we have constant phases. To lead or lag them, the “brain” of the motor speeds up or slows down the electric motor accordingly. The planetary gear converts this difference in rotation into a rotation of the camshaft relative to its sprocket.

Under the new operating conditions of the motor, the influence of the thermal gap in the valve drive increased, so hydraulic compensators were finally used. To reduce friction losses, the engineers ditched conventional cap-type pushrods in favor of rockers with needle bearings. The new mechanism was seasoned with additional oil lines to lubricate the camshaft cams.

An innovation in the oil system is a pump with pressure regulation in two ranges (depending on the engine operating mode), which is necessary to reduce hydraulic losses. To reduce mechanical and friction losses, the engineers tried to lighten the engine elements as much as possible - in this the Japanese followed in the footsteps of their European colleagues. The entire crank mechanism fell under the knife: pistons, connecting rods and crankshaft.

The pistons have a very interesting bottom shape. Usually, for gasoline pistons, it is flat, although sometimes it has recesses for intake valves - counterbores. And here the bottom is convex and even with a large recess in the center. This is done to form a mixture around the spark plug that burns more stably and fully. The lightweight aluminum cylinder block now consists of two parts. It was divided along the axis of the crankshaft into upper and lower. A similar design was also found in some diesel engines. The crankshaft and other components were previously cast iron. Materials in the construction were replaced with steel and aluminum alloys. As a result, the mass of the engine was reduced by 10%, and friction losses - by as much as 30%! Fuel consumption and CO 2 emissions decreased by 15%, the same amount added torque.

The power of motors for Russia is limited, taking into account our taxes: a maximum of 150 hp, but in Europe the same units produce 165 hp.

Having dispensed with supercharging, the Japanese improved all indicators, but the engine turned out to be extremely intricate. A high compression ratio significantly increased the load on the engine elements.

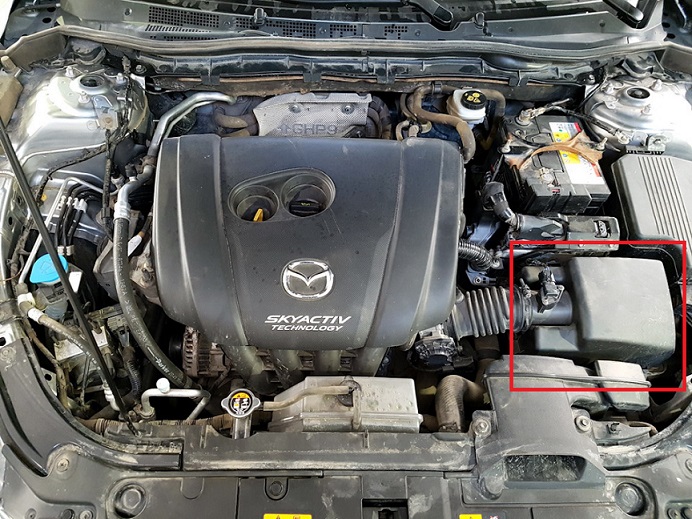

![3 generation [2012 - 2015]](/uploads/56857_780x510_tc2.jpg)