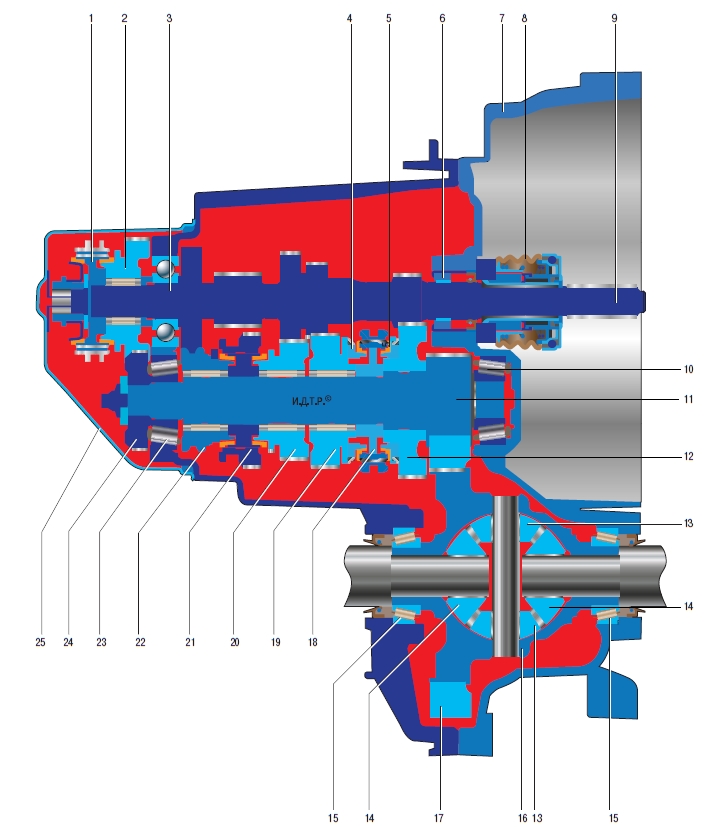

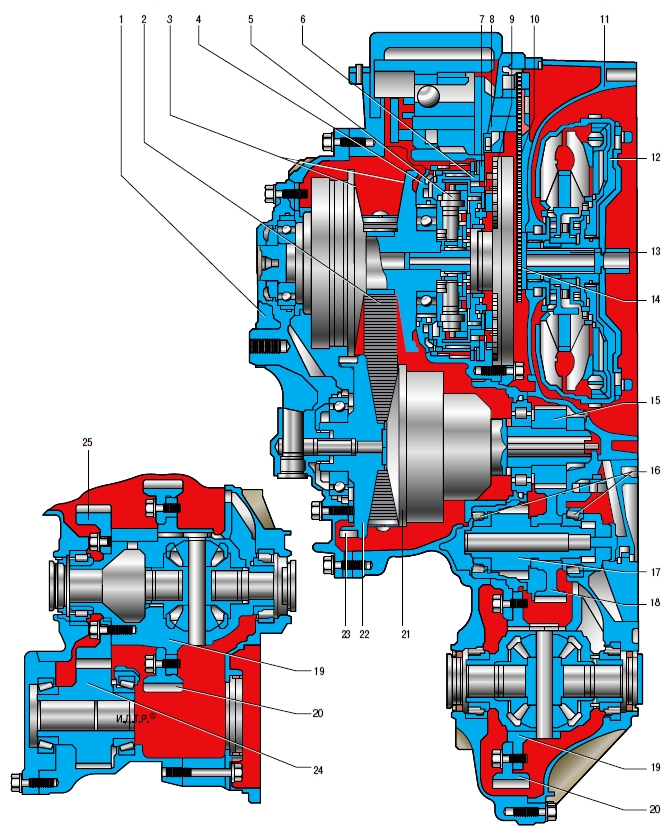

Rice. 6.2. Scheme of a 5-speed manual gearbox model RS5F92R: 1 - synchronizer V and reverse gears; 2 - drive gear V transmission; 3 - rear bearing of the input shaft; 4 - conical synchronizer II gear; 5 - conical synchronizer of 1st gear; 6 - front bearing of the primary shaft; 7 - clutch cover; 8 - clutch release slave cylinder; 9 - input shaft; 10 - front bearing of the secondary shaft; 11 - secondary shaft; 12 - driven gear of the 1st gear; 13 - satellite; 14 - differential gear; 15 - differential bearing; 16 - differential box; 17 – gear wheel of the main transfer; 18 - synchronizer of I and II gears (assembly); 19 - driven gear of the second gear; 20 - driven gear III gear; 21 - synchronizer III and IV gears; 22 - driven gear IV gear; 23 - rear bearing of the secondary shaft; 24 - driven gear V transmission; 25 - gearbox housing cover.

For Nissan Qashqai cars with a 1.6 hp engine. install 5-speed gearboxes model RS5F92R (Fig. 6.2), made according to a two-shaft scheme.

The gearbox and final drive with differential share a common crankcase.

Clutch housing 7 is attached to the front of the gearbox housing. The mechanism for engaging V gear and reverse gear is closed with a separate cover 25.

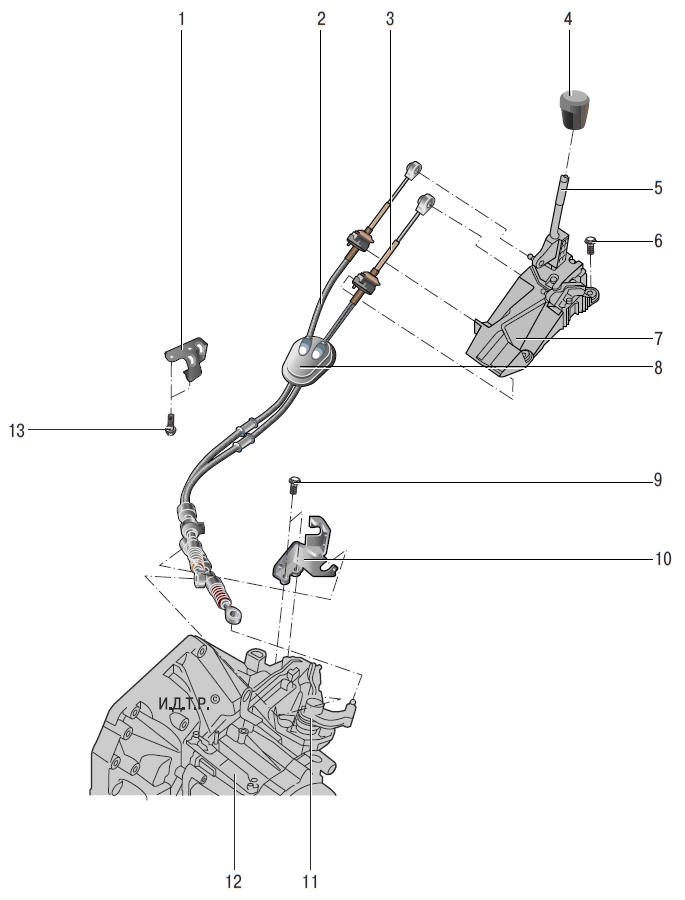

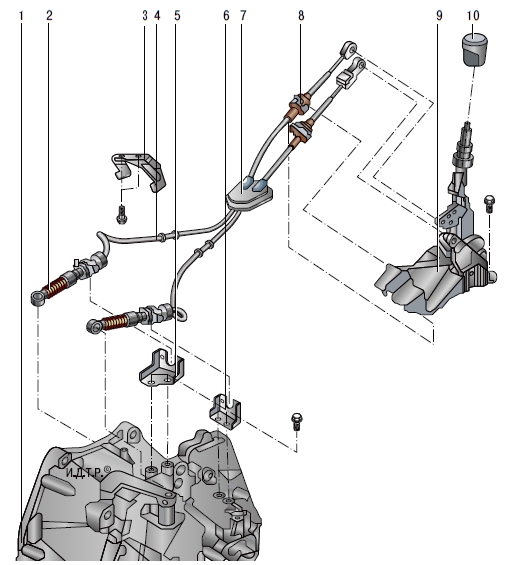

Rice. 6.3. Control drive for a 5-speed manual gearbox model RS5F92R: 1 - cable attachment bracket, 2 - gear shift cable; 3 – a cable of a choice of transfers; 4 – the handle of the gear lever; 5 - gearshift lever; 6, 9, 13 - mounting bolts; 7 – a scene of the lever of a gear change; 8 - cable seal; 10 - bracket for fastening the tips of the cables; 11 - mechanism for selecting and shifting gears; 12 - gearbox.

The control drive of a 5-speed manual gearbox consists of a backstage 7 (see Fig. 6.3) of a gear lever 5 with a ball bearing mounted on the base of the body, selection cables 3 and gear shift 2, as well as a mechanism 11 for selecting and shifting gears located 12 gearboxes on the crankcase. The gear selection and shift cables are structurally different from each other and are not interchangeable.

The main gear is made in the form of a pair of cylindrical gears matched according to noise. Torque is transmitted from the driven gear of the final drive to the differential and then to the front wheel drives.

The differential is conical, free, with two satellites. The tightness of the connection of the internal hinges of the front wheel drive with the differential gears is provided by oil seals. In the lower part of the gearbox housing there is a drain plug, and on the side there is a filler (control) plug.

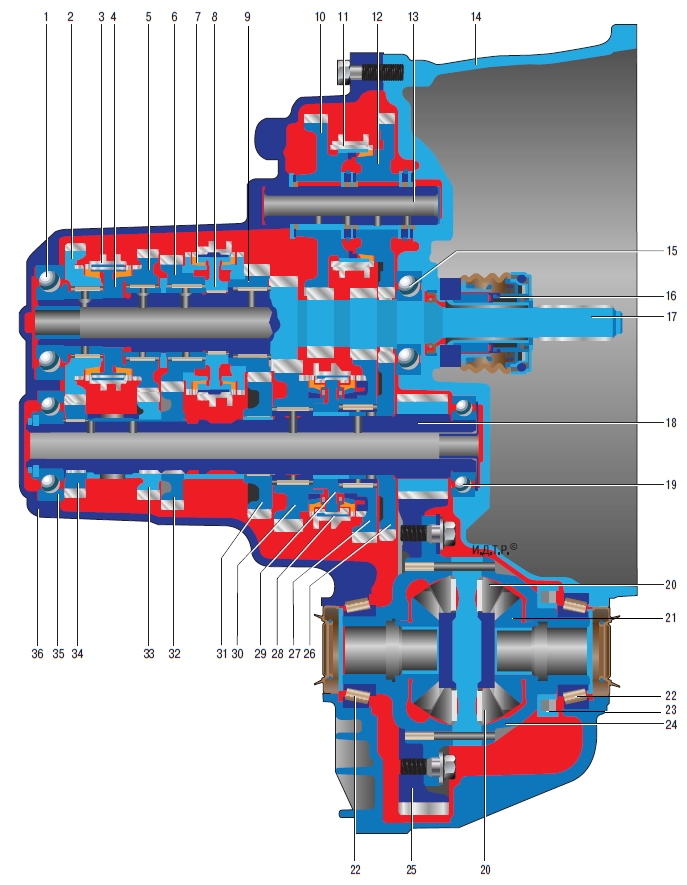

For Nissan Qashqai with 2.0 HP engine. and front-wheel drive, 6-speed manual gearboxes model RS6F52A (Fig. 6.4), made according to a two-shaft scheme, are installed.

Rice. 6.4. Scheme of a 6-speed manual gearbox model RS6F52A (for a car with front-wheel drive): 1 - input shaft rear bearing; 2 - the drive gear of the VI gear; 3 - sliding clutch of the synchronizer of V and VI gears; 4 – coupling hub; 5 - drive gear V transmission; 6 - drive gear IV gear; 7 - sliding clutch of the synchronizer of III and IV gears; 8 – clutch hub; 9 – a leading gear wheel of III transfer; 10 – a back intermediate gear wheel of transfer of a backing; 11 - sliding clutch of the reverse gear synchronizer; 12 – a forward intermediate gear wheel of transfer of a backing; 13 – an intermediate shaft of transfer of a backing; 14 - clutch cover; 15 - front bearing of the input shaft; 16 - clutch release slave cylinder; 17 - input shaft; 18 - secondary shaft; 19 - front bearing of the secondary shaft; 20 - satellite; 21 - differential gear; 22 - differential bearing; 23 – a gear ring of a speedometer; 24 - differential box; 25 – gear wheel of the main transfer; 26 - driven gear reverse gear; 27 - driven gear of the 1st gear; 28 - sliding clutch of the synchronizer of I and II gears; 29 - clutch hub; 30 - driven gear II gear; 31 - driven gear III gear; 32 - driven gear IV gear; 33 - driven gear V transmission; 34 - driven gear VI gear; 35 - rear bearing of the secondary shaft; 36 - gearbox housing. 30 - driven gear II gear; 31 - driven gear III gear; 32 - driven gear IV gear; 33 - driven gear V transmission; 34 - driven gear VI gear; 35 - rear bearing of the secondary shaft; 36 - gearbox housing. 30 - driven gear II gear; 31 - driven gear III gear; 32 - driven gear IV gear; 33 - driven gear V transmission; 34 - driven gear VI gear; 35 - rear bearing of the secondary shaft; 36 - gearbox housing.

The main gear is made in the form of a pair of cylindrical gears of the secondary shaft 16 and gear 25, selected according to noise. Torque is transmitted from the driven gear of the final drive to the differential and then to the front wheel drives.

The gearbox and final drive with differential have a common crankcase 36.

Clutch crankcase 14 is attached to the front of the gearbox crankcase

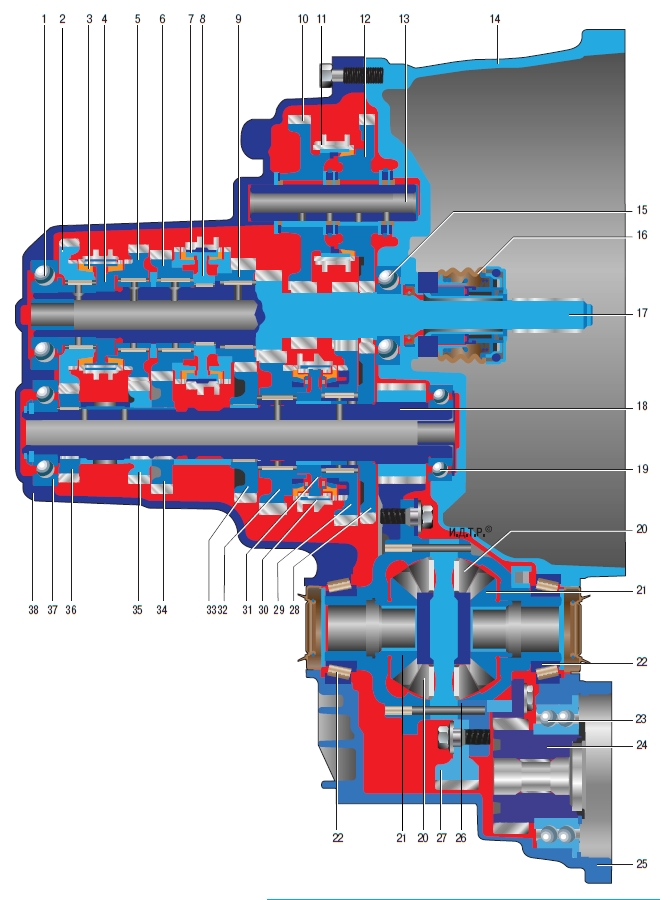

. the same manual gearbox is installed (Fig. 6.5) with a transfer case 25 attached to it.

Rice. 6.5. Scheme of a 6-speed manual gearbox model RS6F52A (for a car with all-wheel drive): 1 - input shaft rear bearing; 2 - the drive gear of the VI gear; 3 - sliding clutch of the synchronizer of V and VI gears; 4 – coupling hub; 5 - drive gear V transmission; 6 - drive gear IV gear; 7 - sliding clutch of the synchronizer of III and IV gears; 8 – clutch hub; 9 – a leading gear wheel of III transfer; 10 – a back intermediate gear wheel of transfer of a backing; 11 - sliding clutch of the reverse gear synchronizer; 12 – a forward intermediate gear wheel of transfer of a backing; 13 – an intermediate shaft of transfer of a backing; 14 - clutch cover; 15 - front bearing of the input shaft; 16 - clutch release slave cylinder; 17 - input shaft; 18 - secondary shaft; 19 - front bearing of the secondary shaft; 20 - satellite; 21 - differential gear; 22 - differential bearing; 23 – transfer case gear bearing; 24 - gear drive of the output shaft of the transfer case; 25 - crankcase transfer case; 26 – gear wheel of selection of power of a drive of back wheels; 27 - differential housing; 28 – gear wheel of the main transfer; 29 - driven reverse gear; 30 - driven gear of the 1st gear; 31 - sliding clutch of the synchronizer of I and II gears; 32 - clutch hub; 33 - driven gear II gear; 34 - driven gear III gear; 35 - driven gear IV gear; 36 - driven gear V transmission; 37 - driven gear VI gear; 38 - rear bearing of the secondary shaft; 39 - gearbox housing. 25 - crankcase transfer case; 26 – gear wheel of selection of power of a drive of back wheels; 27 - differential case; 28 – gear wheel of the main transfer; 29 - driven reverse gear; 30 - driven gear of the 1st gear; 31 - sliding clutch of the synchronizer of I and II gears; 32 - clutch hub; 33 - driven gear II gear; 34 - driven gear III gear; 35 - driven gear IV gear; 36 - driven gear V transmission; 37 - driven gear VI gear; 38 - rear bearing of the secondary shaft; 39 - gearbox housing. 25 - crankcase transfer case; 26 – gear wheel of selection of power of a drive of back wheels; 27 - differential housing; 28 – gear wheel of the main transfer; 29 - driven reverse gear; 30 - driven gear of the 1st gear; 31 - sliding clutch of the synchronizer of I and II gears; 32 - clutch hub; 33 - driven gear II gear; 34 - driven gear III gear; 35 - driven gear IV gear; 36 - driven gear V transmission; 37 - driven gear VI gear; 38 - rear bearing of the secondary shaft; 39 - gearbox housing. 34 - driven gear III gear; 35 - driven gear IV gear; 36 - driven gear V transmission; 37 - driven gear VI gear; 38 - rear bearing of the secondary shaft; 39 - gearbox housing. 34 - driven gear III gear; 35 - driven gear IV gear; 36 - driven gear V transmission; 37 - driven gear VI gear; 38 - rear bearing of the secondary shaft; 39 - gearbox housing.

Torque, in addition to the front wheel drives, is transmitted through the transfer case, cardan gear and rear axle gearbox to the rear wheel drives.

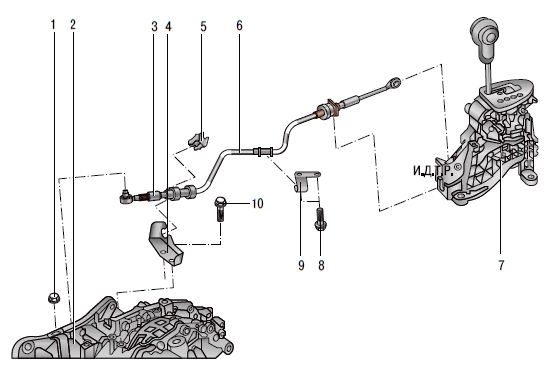

Rice. 6.7. Control drive 6 - speed manual transmission model RS6F52А: 1 - cable attachment bracket, 2 - gear shift cable; 3 – a cable of a choice of transfers; 4 – the handle of the gear lever; 5 - gearshift lever; 6, 10, 15 - mounting bolts; 7 – a scene of the lever of a gear change; 8 - cable seal; 9 – an arm of fastening of a tip of a cover of a cable of a gear change; 11 - bracket for fastening the tip of the sheath of the gear selection cable; 12– lever of the mechanism of a gear change; 13– gear selector lever; 14 - gearbox.

The control drive of a 6-speed manual gearbox consists of a backstage 7 (Fig. 6.7) of a gear lever 5 with a ball bearing mounted on the base of the body, selection cables 3 and gear shift 2, as well as selection mechanisms 13 and gear shift 12 located on crankcase 14 gearboxes. The gear selection and shift cables are structurally different from each other and are not interchangeable.

Rice. 6.6. RE0F10A stepless variator: 1 – variator side cover; 2 - steel flexible belt; 3 - movable half-pulleys of the input shaft; 4 - casing of the planetary gear; 5 - the central gear of the planetary gear; 6 - clutch; 7 - friction brake; 8 - pump of the working fluid of the variator; 9 - pump drive circuit; 10 - gear drum of the pump drive; 11 - casing of the torque converter; 12 - torque converter; 13 - input shaft; 14 - toothed drum of the pump drive chain; 15 - the drive gear of the secondary shaft; 16 - bearings; 17 - reduction gear; 18 - intermediate gear; 19 - differential case; 20 – gear wheel of the main transfer; 21 - movable half-pulleys of the secondary shaft; 22 - parking position gear; 23 - satellite gear planetary gear; 24 - gear drive of the output shaft of the transfer case;

On cars with a 2.0 liter engine, in addition to a 6-speed manual gearbox, a continuously variable CVT (Continuously Variable Transmission) RE0F10A variator is installed (Fig. 6.6), which provides the choice of the optimal gearshift mode for any driving style and various road conditions.

In addition, there is a mode with a manual shift mode, in which during the acceleration of the car, the driver independently chooses the moment of shifting to an overdrive. This allows, if desired, to achieve more intense acceleration compared to automatic mode, making an artificial upshift delay, which allows you to bring the engine speed to the maximum torque range. At the same time, the third-generation electronic control system constantly monitors the vehicle speed and engine load, and eliminates driver error by preventing the driver from shifting up at low speed to avoid engine overload, and downshifting at too high a speed, to prevent exceeding the maximum allowable engine speed. When the vehicle speed decreases, the gears automatically switch to lower gears without the participation of the driver.

When the car comes to a complete stop, 1st gear is automatically engaged. Since the variator uses a V-belt transmission with pulleys of variable diameter, shocks are eliminated when starting and switching. The CVT continuously and smoothly changes the gear ratio as the car accelerates or decelerates.

To repair a manual gearbox (especially a variator), a large set of special tools and appropriate training of the performer are required, therefore, this subsection discusses only maintenance, removal and installation of the gearbox, replacement of its seals, and repair of the drive. To repair the gearbox, contact a specialized service.

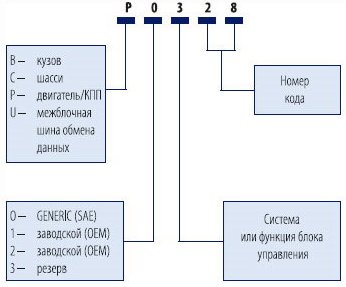

Drive control variator 2 (Fig.6.8) cable. The variator selector is installed in the same place on the floor tunnel as the manual transmission control lever, and is connected to the control unit on the gearbox with a control cable 6. In addition to the control cable, a lock cable is attached to the selector, which does not allow the key to be removed from the ignition lock if the selector lever is not in the P (Park) position.

Rice. 6.8. Variator control drive: 1 - cable end fastening nut, 2 - variator; 3 – a tip of a cable of management of a variator; 4 - bracket for fastening the tip of the cable sheath; 5 - spring retainer of the tip of the cable sheath; 6 – variator control cable; 7 – a scene of the selector of a choice of transfers; 8 – a bolt of fastening of an arm of a cable; 9 – variator control cable bracket; 10 – a bolt of fastening of an arm of a tip of a cover of a cable.

Source: http://nissan-qashqai.dv13.ru/transmissiya/korobka-peredach/

![1 generation [2007 - 2010]](/uploads/Nissan_Qashqai_2007-2010_.jpg)