The design features of the Skoda Octavia engine are considered on the example of an engine with a working volume of 1.6 liters as the most common.

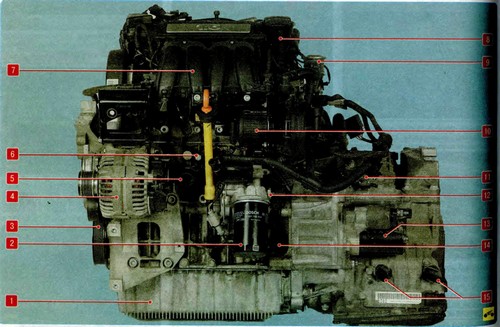

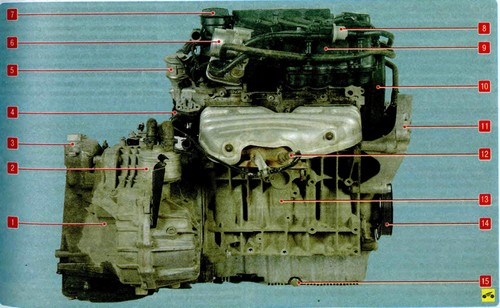

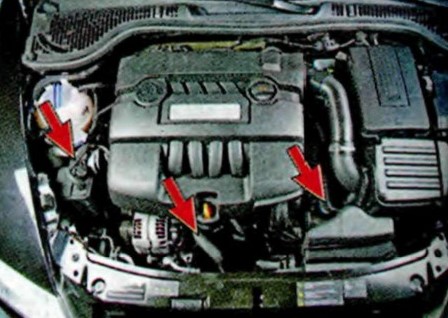

The engine (Fig. 234 and 235) is mounted transversely in front of the Skoda Octavia.

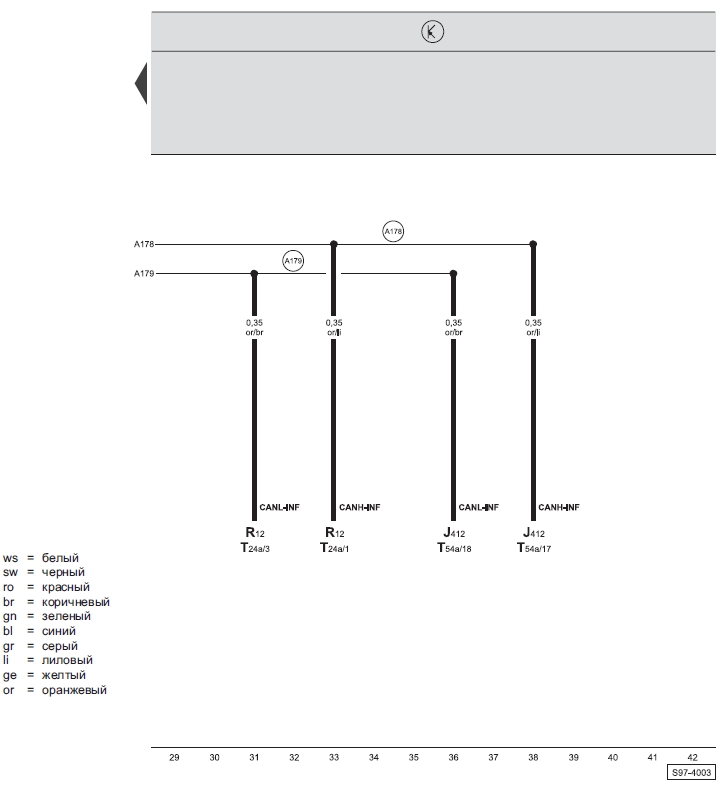

Rice. 234. Power unit (front view in the direction of travel): 1 - oil sump; 2 - oil filter; 3 - auxiliary drive pulley; 4 - generator; 5 - thermostat housing; 6 - knock sensor; 7 - intake manifold; 8 - oil filler neck; 9 - bypass valve; 10 - additional air pump; 11 - automatic transmission selector position sensor; 12 - oil pressure sensor; 13 - starter; 14 - crankshaft position sensor; 15 - gearbox sensors.

Rice. 235. Power unit (rear view in the direction of travel): 1 - gearbox; 2 - AKP heat exchanger; 3 - platform for attaching the left suspension support of the power unit; 4 - water distributor; 5 - bypass valve; 6 - throttle assembly; 7 - oil filler cap; 8 - adsorber valve; 9 - intake manifold receiver; 10 - timing belt cover; 11 - bracket of the right suspension support of the power unit; 12 - control oxygen concentration sensor; 13 - cylinder block; 14 - crankshaft pulley; 15 - oil drain plug.

NOTE

Engine displacement (displacement) is one of the most important design parameters (characteristics) of an internal combustion engine (ICE), expressed in liters (l) or cubic centimeters (cm3). The working volume of the engine largely determines its power and other operating parameters. It is equal to the sum of the working volumes of all engine cylinders. In turn, the working volume of the cylinder is defined as the product of the cross-sectional area of the cylinder and the length of the piston stroke (from BDC to TDC). According to this parameter, long-stroke engines with a piston stroke longer than the cylinder diameter are distinguished, and short-stroke engines with a piston stroke less than the cylinder diameter.

The cylinder head of the engines is made of aluminum alloy according to the transverse cylinder scavenging pattern (inlet and outlet channels are located on opposite sides of the head). Seats and valve guides are pressed into the head. The intake and exhaust valves have one spring each, fixed through the plate with two crackers.

The separation plane of the head and cylinder block is sealed with a gasket, which is a plate molded from sheet metal.

Compression ratio

NOTE

The compression ratio is the ratio of the volume of the above-piston space of the cylinder with the piston position at BDC to the volume of the above-piston space of the cylinder with the piston position at TDC, i.e. to the volume of the combustion chamber, increasing the compression ratio requires the use of fuel with a higher octane rating (for gasoline ICEs) in order to avoid detonation. Increasing the compression ratio in the general case increases its power, in addition, it increases the efficiency of the engine, i.e. helps to reduce fuel consumption. In the 50-60s of the 20th century, one of the trends in engine building was an increase in the compression ratio, which by the beginning of the 70s often reached 11-13. However, this required an appropriate high-octane gasoline, which in those years could only be obtained by adding poisonous tetraethyl lead (leaded gasoline).

The concept of “compression ratio” should not be confused with the concept of “compression”, which means (at a certain structurally determined compression ratio) the maximum pressure created in the cylinder when the piston moves from BDC to TDC (for example, the compression ratio is 10, compression is 14 atm) .

The cylinder block is a single casting that forms the cylinders, the cooling jacket, the upper part of the crankcase and five crankshaft bearings made in the form of crankcase partitions. The blocks are made of aluminum alloy with cylinders bored directly into the body of the block. The main bearing caps are machined complete with blocks and are not interchangeable. Cylinder blocks have special lugs, flanges and holes for attaching parts, components and assemblies, as well as channels of the main oil line.

The crankshaft rotates in main bearings with thin-walled steel liners with an anti-friction layer. The axial movement of the crankshaft is limited by two half rings installed in the grooves of the bed of the middle main bearing.

The cast iron flywheel is mounted on the rear end of the crankshaft and secured with six bolts. A gear rim is pressed onto the flywheel for starting the engine with a starter. In addition to it, a ring gear is made on the flywheel, which ensures the operation of the top dead center sensor of the Skoda Octavia engine management system.

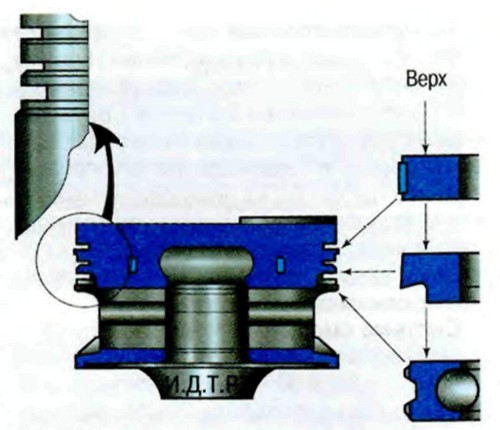

Rice. 236. Piston and piston rings.

Pistons (Fig. 236) are made of aluminum alloy. On the cylindrical surface of the piston head there are annular grooves for the oil scraper and two compression rings.

The piston pins are installed in the piston bosses with a gap and are pressed with an interference fit into the upper heads of the connecting rods, which are connected by their lower heads to the connecting rod heads of the crankshaft through thin-walled liners, similar in design to the main ones. The

connecting rods are steel, forged, with an I-section rod.

Camshaft

The camshaft is driven from the crankshaft by a toothed belt. The camshaft bearing caps are integrated into a monolithic frame structure. The intake and exhaust valves are closed by coil springs and move in guide bushings pressed into the cylinder head. The camshaft lobes drive the valves through roller rocker arms supported by hydraulic lash adjusters.

Combined type lubrication system. Lubrication in the Skoda Octavia engine comes from an oil pump driven through a chain and an asterisk from the toe of the crankshaft. The pump draws oil from the sump through a strainer and forces it through a full flow oil change filter mounted on the outside of the engine. Further, the oil enters the cylinder block through the channels, from where it is distributed to the support (main) bearings of the crankshaft and the camshaft to the block head. Oil is supplied to the connecting rod journals through drillings in the crankshaft, and oil is supplied under pressure to the camshaft bearings and hydraulic compensators. The cams and valves are splash lubricated like all other moving parts of the engine. An oil-liquid heat exchanger is integrated into the lubrication system to cool the oil.

The closed-type crankcase ventilation system does not communicate directly with the atmosphere, therefore, simultaneously with the exhaust of gases, a vacuum is formed in the crankcase under all engine operating modes, which increases the reliability of various engine seals and reduces the emission of toxic substances into the atmosphere.

The system consists of two branches: large and small.

When the Skoda Octavia engine is idling and under low load conditions, when the vacuum in the intake pipe is high, crankcase gases are sucked in by the intake pipe along the small branch of the system.

At full load, when the throttle is open to a large angle. the vacuum in the intake pipe decreases, and in the air supply hose increases. and crankcase gases through a large branch hose connected to a fitting on the block head cover, mainly enter the air supply hose, and then through the throttle assembly into the intake pipe and engine cylinders.

The engine cooling system is sealed, with an expansion tank, and consists of a cooling jacket made in casting and surrounding the cylinders in the block, combustion chambers and gas channels in the cylinder head. Forced circulation of the coolant is provided by a centrifugal water pump driven by a crankshaft timing belt. To maintain the normal operating temperature of the coolant, a thermostat is installed in the cooling system, which closes a large circle of the system when the engine is cold and the coolant temperature is low.

The engine power system consists of an electric fuel pump installed in the fuel tank, a throttle assembly, a fine fuel filter installed under the tank, a fuel pressure regulator installed in the fuel pump module, injectors and fuel lines, and also includes an air filter.

Ignition

system The ignition system of Skoda Octavia engines is microprocessor-based and consists of an ignition module, high-voltage wires and spark plugs. The ignition module is controlled by the electronic control unit of the engine management system. The ignition system during operation does not require maintenance and adjustment.

The power unit (engine with gearbox) is mounted on two supports with elastic rubber elements - lateral right and left, perceiving the main mass of the power unit. The lower torque arm compensates for the torque from the transmission and the loads that occur when starting the car from a standstill, accelerating and braking.

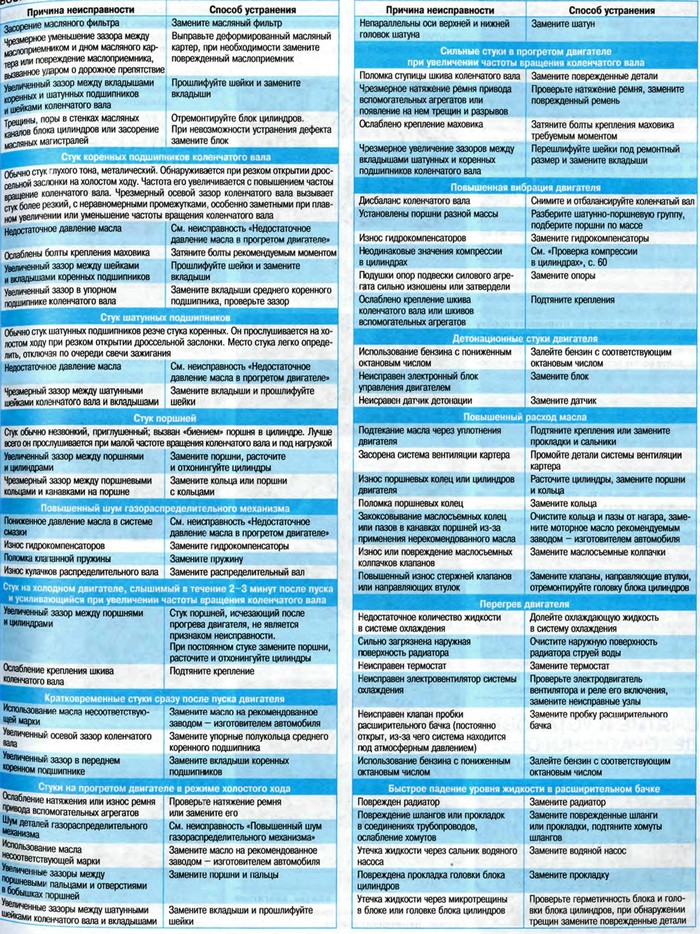

POSSIBLE ENGINE FAULTS, THEIR CAUSES AND REMEDIES

NOTE

This section describes Skoda Octavia engine repair work available in a small workshop, such as replacing seals, power unit suspension mounts, checking compression, adjusting and lapping valves, etc. For the overhaul of the engine with its complete disassembly, special equipment and tools are required, as well as the appropriate technical training of the performer. Therefore, if such repairs are necessary, contact specialized service stations.

USEFUL TIPS

With a certain skill and care, many malfunctions of the engine and its systems can be quite accurately determined by the color of the smoke coming out of the exhaust pipe. Blue smoke indicates that oil has entered the combustion chambers, and constant smoking is a sign of severe wear of the parts of the cylinder-piston group. The appearance of smoke during regassing, after prolonged cranking by the starter, after long idling or immediately after engine braking, as a rule, indicates wear on the valve stem seals. Black smoke is a sign of too rich a mixture due to a malfunction of the engine control system or injectors. Blue or thick white smoke with an admixture of moisture (especially after the engine has overheated) means that coolant entered the combustion chamber through a damaged cylinder head gasket. If this gasket is severely damaged, the liquid sometimes enters the oil sump, the oil level rises sharply, and the oil itself turns into a cloudy whitish emulsion. White smoke (steam) when the engine is cold in wet or cold weather is normal. Quite often you can see a car standing in the middle of a city traffic jam with an open hood, emitting puffs of steam.

Overheat. It is better, of course, not to allow this, often looking at the temperature gauge. But no one is immune from the fact that the thermostat, electric fan may suddenly fail, or coolant will simply flow. If you miss the moment of overheating, do not panic and do not aggravate the situation. Overheating is not as bad as its possible consequences. Never immediately turn off the engine - it will get a heat stroke and, possibly, having cooled down, will refuse to start at all. Having stopped, let it idle, while the fluid circulation will remain in the system. Turn on the heater to maximum power and open the hood. If possible, pour cold water over the radiator. Stop the engine only when the temperature has dropped. But never immediately open the radiator cap: on an overheated engine, a geyser from under an open plug is provided. Take your time, let everything cool down, and you will save the health of the machine and your own health. Almost all instructions for the car contain a recommendation to depress the clutch when starting the engine. This recommendation is justified only in case of starting in severe frost, so as not to waste battery energy on turning the shafts and gears of the gearbox in thickened oil. In other cases, this measure is aimed only at ensuring that the car does not move if the gear is switched on due to forgetfulness. Such a technique is harmful to the engine, since when the clutch is depressed, a significant force is transmitted through it to the thrust bearing of the crankshaft, and during start-up (especially cold), lubrication is not supplied to it for a long time. The bearing wears out quickly the crankshaft receives axial play, starting off begins to be accompanied by strong vibration. In order not to spoil the engine, make it a habit to check the position of the gear lever before starting and start the engine with the parking brake applied, without depressing the clutch unless absolutely necessary.

Source: http://skoda-octavia2.ru/index.php/dvigatel-skoda-octavia/59-osobennosti-konstruktsii-dvigatelya-1-6-l.html

![1 generation [restyling] [2000 - 2010]](/uploads/Skoda_Octavia_2000_-_2010_.jpg)

![2 generation [2004 - 2008]](/uploads/Skoda_Octavia_2004_-_2012_.jpg)

![3 generation [2013 - 2017]](/uploads/Skoda_Octavia_2013_-_2015_.jpg)