Tools:

- Mounting blade

- A set of keys

Parts and consumables:

- Rubber-metal hinges

- rubber pads

Notes:

The rear wheel suspension is equipped with trapezoidal levers. The suspension beam is made of steel, the trapezoidal arms are made of a hollow aluminum profile. This design is characterized by low weight and compactness. This makes it possible to achieve both the front-wheel drive version and the all-wheel drive version with a low boot floor and an optimal width of the load compartment.

All lever elements through rubber-metal supports are hinged to an elastically mounted suspension beam, which ensures effective damping of body vibrations. Suspension of the rear suspension is carried out by coil springs and two shock absorbers, which are located separately and can be easily removed.

Welding and straightening work on the bearing and guiding elements of the front suspension is not allowed. Self-locking nuts, as well as rusty bolts/nuts, must be replaced during repairs.

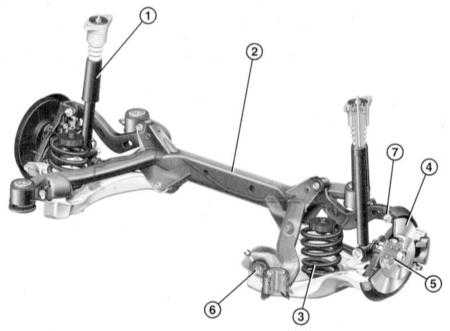

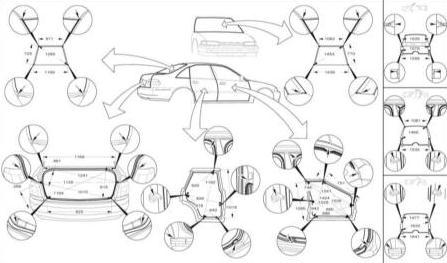

Rear wheel suspension:

1 - shock absorber;

2 - suspension beam;

3 - helical spring;

4 - brake disc;

5 - wheel bearing;

6 - convergence adjustment mechanism;

7 - camber adjustment mechanism.

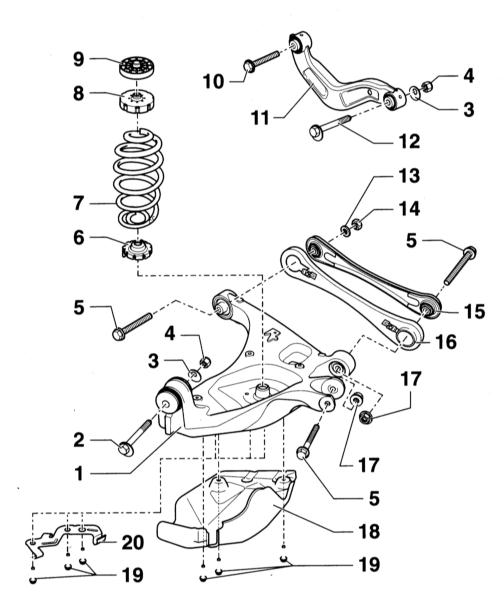

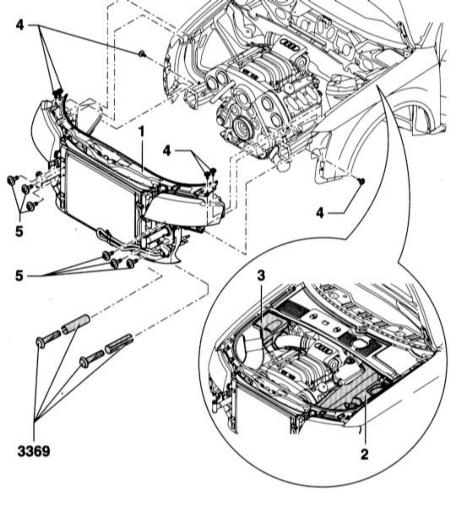

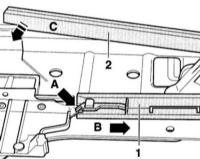

Suspension arms (front wheel drive models):

1 - trapezoidal lever;

2 - eccentric screw;

3 - eccentric washer;

4 - nut;

5 - combined screw;

6 - lower spring support;

7 - helical spring;

8 - top spring support;

9 - upper spring support, only for running gear designed for bad roads;

10 - combined screw;

11 - transverse lever;

12 - eccentric screw;

13 - washer;

14 - nut;

15 - transverse thrust;

16 - shield for protection against ingress of stones, only for the undercarriage, designed for bad roads;

17 - nut with shoulder;

18 - shield for protection against ingress of stones, only for the undercarriage, designed for bad roads;

19 - bolt with shoulder;

20 - parking brake cable holder.

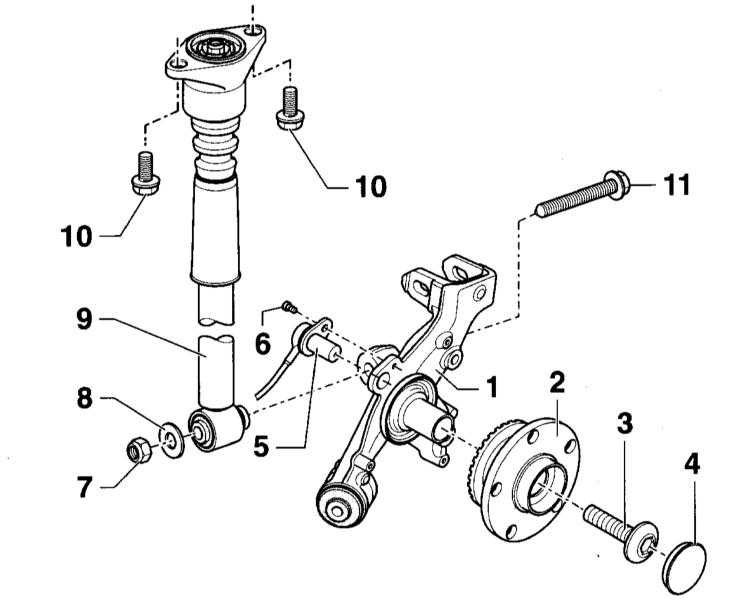

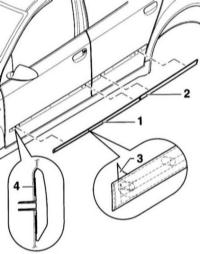

Shock absorber, knuckle and wheel hub:

1 - fist, front-wheel drive models;

2 - hub with wheel bearing;

3 - bolt with shoulder;

4 - anther;

5 - wheel speed sensor;

6 - screw with an internal hexagon;

7 - nut;

8 - washer;

9 - shock absorber;

10 - combined bolt;

11 - combined bolt.

1 . Carry out all checks and work from the bottom of the car mounted on a lift or inspection ditch (with the front wheels hanging out).

2 . Find out if there are any cracks on the suspension parts or traces of rubbing against road obstacles or the body, deformation of the levers, stabilizer bar, rear body parts at the attachment points of suspension units and parts.

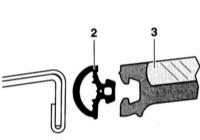

3 . Check the condition of the rubber-metal hinges, rubber cushions, the condition (settlement) of the suspension springs.

Note:

Rubber-metal hinges and rubber pads must be replaced in case of ruptures and one-sided buckling of rubber, as well as when cutting their end surfaces. Signs of aging, cracks, as well as one-sided bulging of the rubber mass are not allowed on rubber-metal hinges. Replace defective parts.

4 . Check the absence of mechanical damage (deformations, cracks, etc.) of the suspension elements.

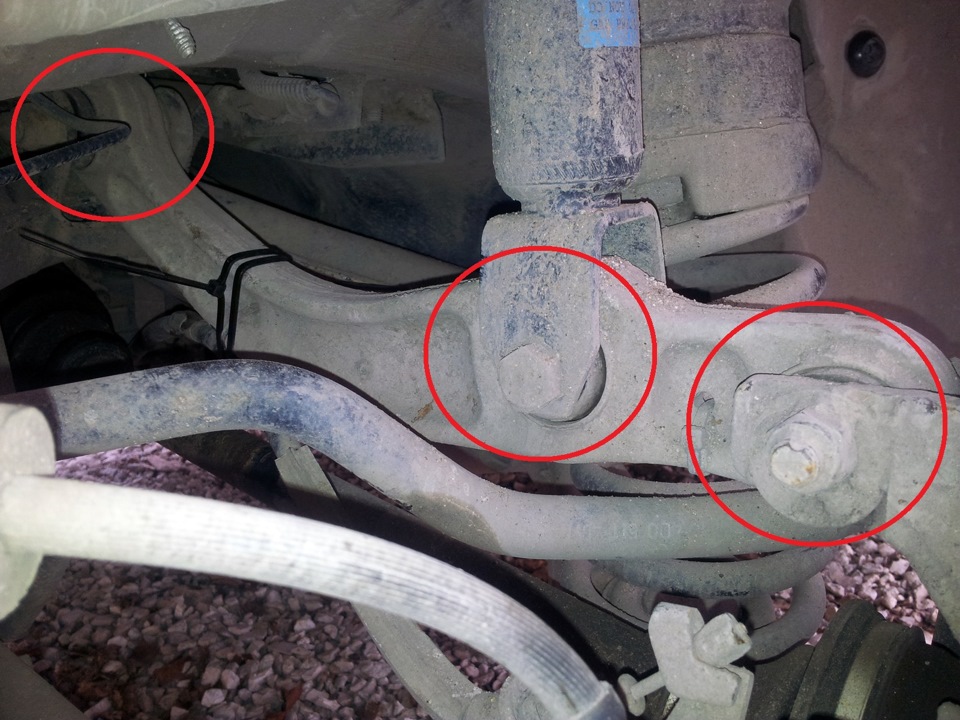

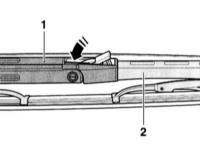

5 . Inspect the rubber bushings of the lower shock mount and shock absorbers. Shock absorbers are not allowed to drip liquid and “sweating”.

6 . Remove protective shields from both sides of the vehicle.

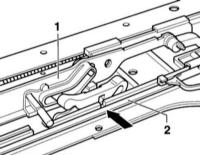

7 . Check the rubber-metal hinges (silent blocks) of the trailing arm of the rear suspension to the car body.

8 . Using a spudger, check the inner and outer bushings of the rear lower arms and the outer bushings of the front lower arms for play.

9 . Similarly, check the inner and outer silent blocks of the upper arms of the rear suspension.

10 . While rocking the anti-roll bar up and down, check for play in the stabilizer link and the rubber pads on the stabilizer bar.

11 . Check springs and compression buffers.

Note:

Pay attention to the exhaust system. Extraneous knocks published by her are often mistaken for a knock in the rear suspension. The use of non-standard parts or the breakage of the muffler suspension elements can cause a strong knock, especially during regassing. To check, stop the engine, carefully inspect the exhaust system, check the reliability of the mounting and suspension of the muffler. Grasping the end of the exhaust pipe, shake the muffler up and down and from side to side - there should be no knocks.

The article is missing:

- High-quality repair photos

Source: http://audi-a4-2000manual.narod.ru/audi-767-10.m_id-67.m_id2-69.html

![B6 [2000 - 2005]](/uploads/Audi_A4_2000-2005_B6_.jpg)