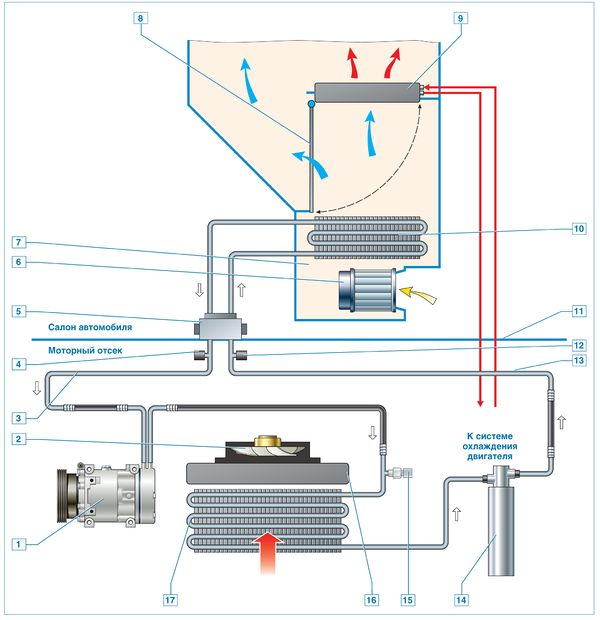

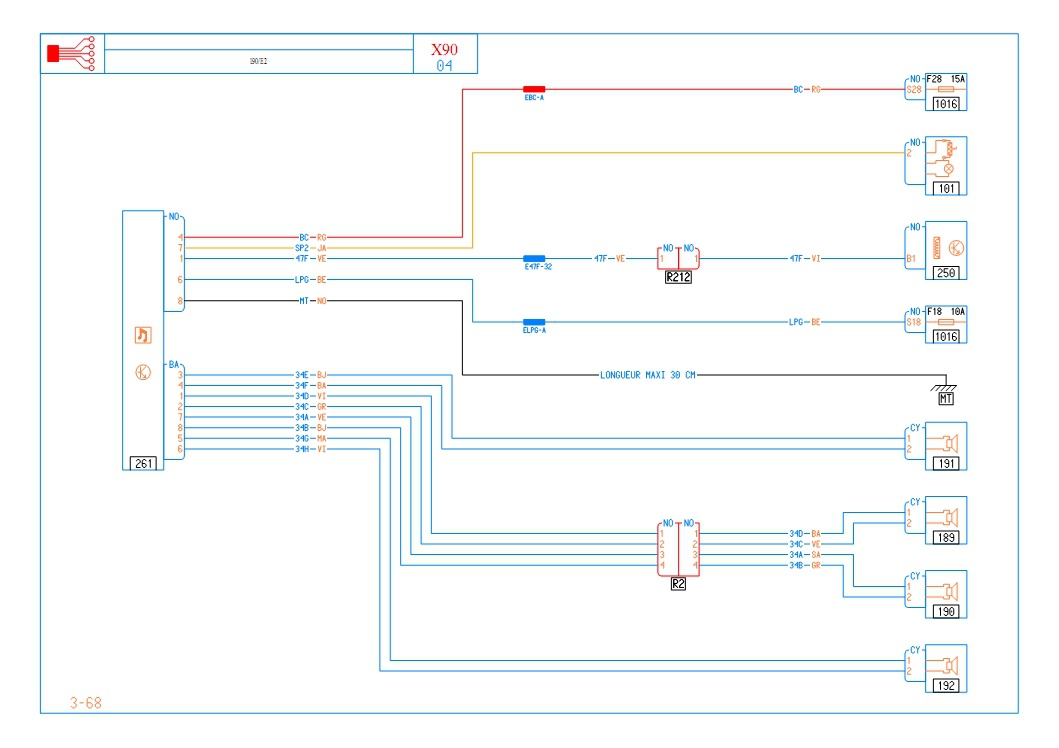

Scheme of the ventilation, heating and air conditioning system :

1 - compressor;

2 - fan of the engine cooling system;

3 - low pressure pipeline;

4 - valve for charging and discharging refrigerant from the low pressure pipeline;

5 - reducer;

6 - heater fan;

7 - heater body;

8 - damper of the temperature controller;

9 - heater radiator;

10 - evaporator;

11 — bulkhead shield;

12 - valve for charging and discharging refrigerant from the high pressure pipeline;

13 - high pressure pipeline;

14 - receiver;

15 - refrigerant pressure sensor;

16 - radiator of the engine cooling system;

17 - condenser

The car can be equipped with either a ventilation and heating system, or a ventilation, heating and air conditioning system, which serve to create the most comfortable conditions for the driver and passengers, regardless of weather conditions.

The ventilation and heating system includes: a heater, a heater fan, air ducts and deflectors. Through air ducts, air from the heater is supplied to the windshield and side window vents, to the central and side vents on the instrument panel, as well as to the ventilation openings in the heater casing to supply air to the driver's and passengers' feet.

Ventilation, heating and air conditioning

control unit The system is controlled by turning the handles located on the ventilation, heating and air conditioning control unit. The control unit is installed on the instrument panel console.

The heater is installed under the instrument panel in the center, the air ducts are fixed under the transverse beam of the instrument panel. The heater housing contains a heater fan, distribution dampers that direct air flows to certain areas, and a heater radiator connected by hoses to the engine cooling system.

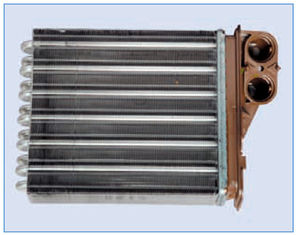

Heater Radiator

Coolant is continuously circulated through the heater core. Depending on the position of the damper associated with the temperature controller, outside air can pass through the heater core or bypass it.

Heater fan

When the car is moving, air enters the heater through the holes located in the left and right decorative overlays of the front panel. To increase the air supply to the passenger compartment while the car is moving, as well as in the parking lot, the heater fan is used.

The air supply intensity is determined by the fan speed. The fan motor, depending on the connection of an additional resistor, can rotate at four different speeds.

The air flow in the cabin is controlled by the air flow distribution regulator, which is connected by rods to the dampers.

By controlling the dampers, the regulator directs air flows through the air ducts to the central and side vents, to the lower ventilation openings in the heater casing, as well as to the windscreen grilles located in the instrument panel.

Air outlet valves from the passenger compartment (when the rear bumper is removed)

Air exits the passenger compartment through openings located on top of the trunk sides and then out through the valves installed behind the rear bumper sidewalls.

An air recirculation system is used to accelerate the heating of the passenger compartment and prevent the entry of outside air into the passenger compartment (when the car is moving along smoky, dusty sections of the road). When the lever for switching on the air recirculation mode is moved, the damper of the recirculation system blocks the access of outside air to the car interior, while the air in the car interior begins to circulate in a closed circuit without exchange with outside air.

Some cars are equipped with an air conditioning system. The air conditioning system is designed to reduce the temperature and humidity in the cabin. The air conditioner is turned on by pressing the air conditioner switch button located in the ventilation, heating and air conditioning control unit, while the heater fan must be turned on. When the air conditioner is turned on, the warning lamp next to the air conditioner switch button lights up.

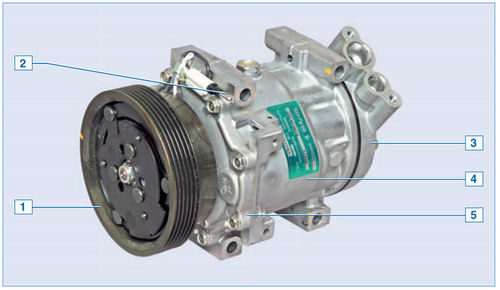

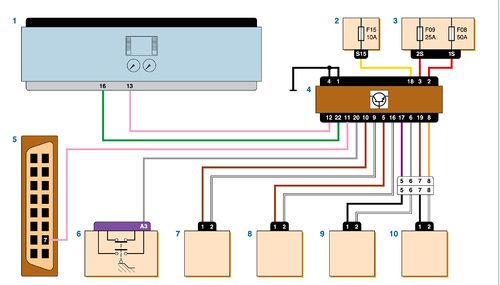

Air conditioner compressor:

1 - a pulley with an electromagnetic clutch;

2 - output of the wire of the electromagnetic clutch;

3 - back cover;

4 - body;

5 — a forward cover

The conditioner compressor is established on an arm of the engine in front, under the generator. The air conditioning compressor is driven by a V-ribbed belt from the accessory drive pulley. A frictional electromagnetic clutch is built into the compressor pulley, which connects and disconnects the compressor shaft with the pulley according to the signals from the engine ECU.

After the compressor, the refrigerant vapor enters the condenser located in front of the radiator of the engine cooling system.

Next, the refrigerant enters the receiver, which is mounted on the condenser, on the left side. From the receiver, the refrigerant enters the gearbox, and then to the evaporator, located under the instrument panel in the heater housing. The air thus cooled enters the passenger compartment. From the evaporator, the refrigerant is again sucked in by the compressor, and the working cycle is repeated. The high and low pressure pipelines are equipped with valves for charging and discharging refrigerant from the air conditioning system.

Refrigerant pressure sensor A refrigerant pressure

sensor is installed in the pipeline between the compressor and the condenser. The pressure sensor sends a signal to the ECU, which controls the electric fan of the engine cooling system, depending on the amount of coolant pressure and vehicle speed. In addition, according to the pressure sensor signals, the ECU turns off the air conditioning compressor when the refrigerant pressure in the system drops to 2.0 bar and when the pressure rises to 27.0 bar. A shut-off valve is installed in the pipeline fitting, under the pressure sensor, which closes when the sensor is unscrewed. Therefore, when replacing the pressure sensor, refrigerant leakage from the air conditioning system will not occur.

The refrigerant in the air conditioning system is under high pressure. When working on the depressurization of the air conditioning system, avoid contact of the refrigerant with the eyes, skin and respiratory tract. Any work with refrigerant must be carried out only in a ventilated area.

When filling the air conditioning system, use only materials recommended by the manufacturer.

It is forbidden to carry out welding or soldering work on the components of the air conditioning system. Work on the repair and maintenance of the air conditioning system should be carried out at specialized services.

To search for leaks in the system, special equipment is used, while a special contrast agent will need to be injected into the system. After removing the refrigerant from the system, be sure to pump out air to remove residual moisture. Before filling the system, it is necessary to add special oil recommended by the manufacturer.

Source: http://wiki.zr.ru/Heating_Repair_Logan_2005

![1 generation [2004 - 2013]](/uploads/Renault_Logan_2004-2009_.jpg)

![2 generation [2013 - 2021]](/uploads/Renault_Logan_2013-2015_.jpg)