Tool:

- Jack

- Support legs

- torque wrench

Parts and consumables:

- MoS2 lubricants for connecting the input shaft, e.g. MOLYKOTE BR 2

To remove the gearbox, you need to raise the car as high as possible. Removing a gearbox requires some experience. Therefore, only the main provisions are described here, aimed at an experienced mechanic.

Withdrawal

The cabin air filter box must first be removed.

1. Disconnect the negative (-) battery cable with the ignition off.

Notes:

Before disconnecting the cable, find out the security code of the radio, if any.

2. For safety reasons, insulate the terminal of the cable going to the negative pole of the battery to prevent accidental contact with the battery poles.

3. Lift the car and remove the bottom facing.

Auto on support racks.

Lower engine cover.

Notes:

Raise the gearbox slightly at the rear engine/transmission mount using a garage jack and wood shim.

Only after that, disconnect the rear beam of the engine / gearbox.

4. Support the gearbox with a garage jack and a piece of wood.

5. Remove a back beam of the engine/transmission for what turn away bolts of fastening.

Rear engine/gear box.

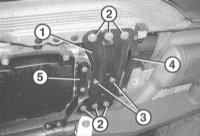

Engine Rear Beam Components:

1 - rear beam of the engine / gearbox;

2 - fastening bolt;

3 - fastening bolt;

4 - engine compartment cover holder;

5 - exhaust system holder.

6. Disconnect the holder of a cover of an impellent compartment.

7. Disconnect the release system holder.

8. Remove the downpipe.

9. Disconnect the rear silencer from the suspension in the area of the additional silencer, lower it slightly and secure it in this position with a wire.

10. Turn away from below a strip of weight between a check point and a body.

11. Remove the starter.

12. Disconnect the speedometer inductive sensor connector.

13 . Remove the cardan shaft, refer to the appropriate section.

Notes:

The front flange of the driveshaft remains on the driveshaft, not on the gearbox.

14. Remove the gearshift linkage cover from the gearbox and disconnect the linkage from the gearbox.

15. Disconnect from the central block, after having removed a lock finger.

16. Disconnect draft of switching.

17. Disconnect the gearbox from the cylinder block.

18. Slowly lower the garage lift, lowering the transmission slightly. Remove the gearbox horizontally back from the guide pins and remove from the clutch.

19. Lower the gearbox.

Notes:

Lower the gearbox only when the input shaft of the gearbox has come out of the clutch disc, otherwise the clutch disc may be damaged.

Installation

1. Before installation, check the clutch.

2. Check the ease of movement of the clutch release bearing. If the noise of the clutch release bearing was heard before removal when disengaging the clutch, replace the bearing.

Notes:

On engines with a dual-mass flywheel, the spline connection of the clutch disc is nickel-plated. Therefore, the gearbox input shaft does not need to be lubricated. The hallmark of a dual-mass flywheel clutch disc is the absence of damper springs.

3. Engines without dual mass flywheel: Clean the input shaft spline and lubricate with a thin film of MoS2 grease, such as MOLYKOTE BR 2. Do not apply too much grease, otherwise grease may get on the friction surfaces of the clutch, resulting in malfunction of the clutch . The required amount of lubricant is according to the size of the corn kernel.

4. Raise the gearbox and enter horizontally into the clutch. If during installation the input shaft of the gearbox is not fixed in the clutch disc, turn the shaft by hand from behind the flange for the driveshaft.

5. Fix the gearbox on the engine with a torque of 40Nm.

6. Install the starter.

7. Connect the switching rod, having previously lubricated the ball joint with a thin layer.

8. Connect to the central unit and secure it with the lock pin.

9. Connect the shift rod to the gearbox, install the cover.

10. Connect the flanges of the cardan shaft and gearbox. The tightening torques of the self-locking nuts of the cardan shaft flange to the gearbox are given in the Specifications.

11. Dock the connector of the inductive speedometer sensor.

12. Fix a back support of the engine/gearbox the moments specified in Specifications.

13. Fasten the ground cable to the gearbox and body.

14. Fix the holder for a cover of an impellent compartment.

15. Fix the holder of a reception pipe of system of release.

16. Reinstall the exhaust system.

17. Check the oil level in the gearbox, add oil if necessary.

18. Check up adjustment of a gear change, if necessary adjust on HUNDRED.

19. Establish the bottom facing of an impellent compartment.

20. Lower the car onto its wheels.

21. Attach a negative cable (-) to the storage battery at the switched off ignition. Install the cabin air filter box. Enter the radio code and set the time on the clock.

The article is missing:

- Tool photo

- Photo of parts and consumables

- High-quality repair photos

Source: http://www.auto-knigi.com/model/mb_c/8_2/3

![W203/S203/CL203 [2000 - 2004]](/uploads/mercedes-c-klass-w203.jpg)