Basic information

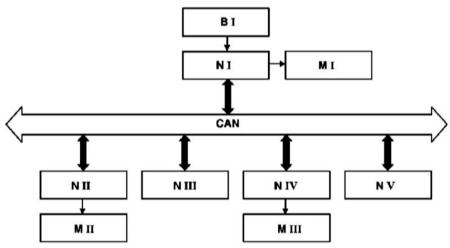

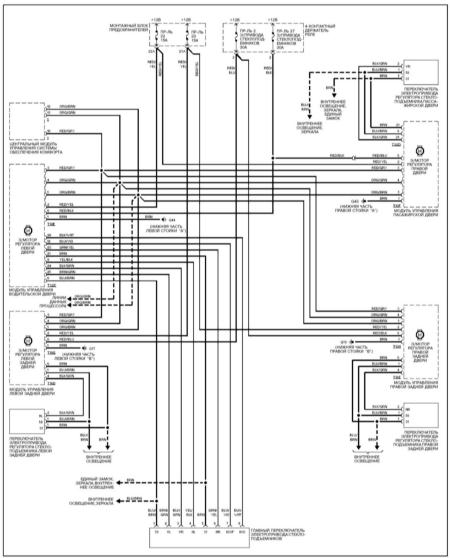

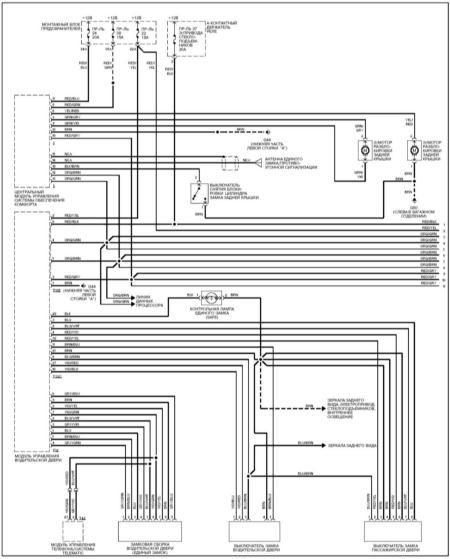

The car uses several CAN (Controller Area Network) data exchange network buses between control units (modules) of various systems and controllers of the car's executive devices.

Individual control units are networked with each other and can exchange data.

The bus is bidirectional, i.e. any device connected to it can receive and transmit messages.

The signal from the sensitive element (sensor) enters the nearest control unit, which processes it and transmits it to the CAN data bus.

Any control unit connected to the CAN data bus can read this signal, calculate the value of the control action based on it, and control the servo actuator.

CAN communication

- B - Sensor 1

- CAN - Data bus

- M - Executive elements I - III (servo mechanisms)

- N - Control units (controllers) I - V

Benefits

With the usual cable connection of electrical and electronic devices, each control unit is directly connected to all sensors and actuators from which it receives measurements or which it controls.

The complication of the control system leads to excessive length or multiple cable lines.

Compared to standard cabling, the data bus provides:

- Reducing the number of cables. The wires from the sensors are pulled only to the nearest control unit, which converts the measured values into a data packet and transfers it to the CAN bus.

- Any control unit can control the actuator, which receives the corresponding data packet via the CAN bus, and on its basis calculates the value of the control action on the servomechanism.

- Improved electromagnetic compatibility.

- Reducing the number of plug connections and reducing the number of contact outputs on control units.

- Weight loss.

- Reducing the number of sensors, because signals from one sensor (for example, from a coolant temperature sensor) can be used by different systems.

- Improving diagnostic capabilities. Because the signals of one sensor (for example, a speed signal) are used by different systems, then if a fault message is issued by all systems using this signal, the sensor or control unit that processes its signals is usually faulty. If the error message comes from only one system, although this signal is also used by other systems, then the cause of the malfunction is most often contained in the processing control unit or servomechanism.

- High data rate – up to 1 Mbit/s possible with a maximum line length of 40 m. At present, data rates on vehicles range from 83 Kbit/s to 500 Kbit/s.

- Several messages can be transmitted in turn on the same line.

The CAN data bus consists of a two-wire wire made in the form of a twisted pair. All devices (device control units) are connected to this line.

Data transfer is carried out with duplication on both wires, and the logical levels of the data bus are mirrored (that is, if a logical zero level is transmitted on one wire, then a logical one level is transmitted on the other wire, and vice versa).

The two-wire transmission scheme is used for two reasons: to detect errors and as a basis for reliability.

If a voltage spike occurs on only one wire (for example, due to EMC (electromagnetic compatibility) problems), then the receiver units can identify this as an error and ignore this voltage spike.

If there is a short circuit or a break in one of the two wires of the CAN data bus, then thanks to the integrated software and hardware system of reliability, there will be a switch to the single-wire mode. A damaged transmission line will not be used.

The order and format of messages transmitted and received by users (subscribers) is defined in the data exchange protocol.

A significant distinguishing feature of the CAN data bus compared to other bus systems based on the principle of subscriber addressing is message-related addressing.

This means that each message on the CAN data bus is assigned its permanent address (identifier), marking the content of this message (for example: coolant temperature). The CAN data bus protocol allows the transmission of up to 2048 different messages, with addresses from 3 to 2048 being permanently fixed.

The amount of data in one message on the CAN data bus is 8 bytes.

The receiver unit processes only those messages (data packets) that are stored in its list of messages received via the CAN data bus (acceptance check).

Data packets can only be transmitted if the CAN data bus is free (i.e. if the last data packet is followed by a 3-bit interval and no control unit starts transmitting a message).

In this case, the logical level of the data bus must be recessive (logical "1").

If several control units start transmitting messages at the same time, then the priority principle takes effect, according to which the message on the CAN data bus with the highest priority will be transmitted first without loss of time or bits (arbitration of requests for access to the common data bus).

Each control unit that loses the right to arbitrate will automatically switch to receive and retry to send its message as soon as the CAN data bus is free again.

In addition to data packets, there is also a request packet for a specific message on the CAN data bus.

In this case, the control unit, which can provide the requested data packet, responds to this request.

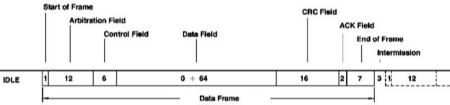

Data Packet Format

In normal transmission mode, data packets have the following block configurations (frames):

• Data Frame (message frame) for transmitting messages on the CAN data bus (eg coolant temperature).

• Remote Frame (request frame) for requesting messages on the CAN data bus from another control unit.

• Error Frame All connected control units are notified that an error has occurred and the last message on the CAN data bus is invalid.

The CAN data bus protocol supports two different CAN data bus message frame formats that differ only in the length of the identifier:

- standard format;

- extended format.

The standard format is currently used.

The data packet for transmitting messages on the CAN data bus consists of seven consecutive fields:

• Start of Frame (start bit): Marks the beginning of the message and synchronizes all modules.

• Arbitration Field (identifier and request): This field consists of an identifier (address) of 11 bits and 1 control bit (Remote Transmission Request-Bit). This control bit marks the packet as a Data Frame (message frame) or as a Remote Frame (request frame) without data bytes.

• Control Field (control bits): The control field (6 bits) contains the IDE bit (Identifier Extension Bit) for recognizing the standard and extended format, a spare bit for subsequent extensions and - in the last 4 bits - the number of data bytes embedded in the Data Field. (data field).

• Data Field (data): The data field can contain from 0 to 8 bytes of data. A message on the CAN data bus with a length of 0 bytes is used to synchronize distributed processes.

• CRC Field (Cyclic-Redundancy-Check Field): The CRC (Cyclic-Redundancy-Check Field) field contains 16 bits and is used to check transmission error detection.

• ACK Field (Acknowledgement Field): The ACK (Acknowledgment Field) field contains the acknowledgment signal of all receiver units that have received a message on the CAN bus without errors.

• End of Frame : Marks the end of the data packet.

• Intermission : Interval between two data packets. The interval must be at least 3 bits. After that, any control unit can transmit the next data packet.

• IDLE (idle mode): If no control unit sends messages, the CAN bus remains in idle mode until the next data packet is sent.

Priorities

In order to process data in real time, it must be possible to transfer them quickly.

This not only requires a link with a high physical data rate, but also requires that a common CAN bus be quickly provided if several control units need to send messages at the same time.

In order to distinguish between the messages transmitted on the CAN data bus according to the degree of urgency, different priorities are provided for individual messages.

Ignition timing, for example, has the highest priority, slip values have medium, and the outside temperature has the lowest priority.

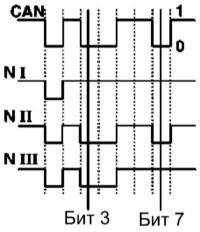

The priority with which a message is transmitted over the CAN bus is determined by the identifier (address) of the corresponding message.

An identifier corresponding to a smaller binary number has a higher priority, and vice versa.

The CAN data bus protocol is based on two logical states: The bits are either "recessive" (logical "1") or "dominant" (logical "0"). If a dominant bit is transmitted by at least one module, then recessive bits transmitted by other modules are overwritten.

Example

If several control units start data transmission at the same time, then the conflict of access to the common data bus is resolved by "bit-wise arbitration of common resource requests" using the corresponding identifiers.

When transmitting the identifier field, the transmitter checks after each bit whether it still has the right to transmit, or whether another control unit is already transmitting a message with a higher priority on the CAN data bus.

If the recessive bit transmitted by the first transmitter unit is overwritten by the dominant bit of another transmitter unit, then the first transmitter unit loses its right to transmit (arbitration) and becomes the receiver unit.

The first control block (NI) loses arbitration from the 3rd bit.

The third control block (N III) loses arbitration from the 7th bit.

The second control unit (N II) retains the right to access the CAN data bus and can transmit its own message.

Other control units will only attempt to transmit their messages on the CAN data bus when it is free again. In this case, the right to transmit will again be granted in accordance with the priority of the message on the CAN data bus.

Error recognition

Interference can lead to errors in data transmission. Such transmission errors should be recognized and corrected. The CAN data bus protocol distinguishes between two levels of error recognition:

- mechanisms at the Data Frame level (message frame);

- bit-level mechanisms.

Mechanisms at the Data Frame level

Cyclic-Redundancy-Check:

Based on the message transmitted via the CAN data bus, the transmitter calculates control bits that are transmitted along with the data packet in the "CRC Field" field (checksums). The receiver unit recalculates these control bits on the basis of the message received via the CAN data bus and compares them with the control bits received with this message.

frame check:

This mechanism checks the structure of the transmitted block (frame), that is, bit fields with a given fixed format and the length of the frame are rechecked.

Errors detected by Frame Check are marked as format errors.

Bit level mechanisms

Monitoring:

Each module, when transmitting a message, monitors the logical level of the CAN data bus and determines the differences between the transmitted and received bits. This ensures reliable recognition of global and local bit errors that occur in the transmitter unit.

Bit Stuffing:

In each data packet, between the "Start of Frame" field and the end of the "CRC Field" field, there must be no more than 5 consecutive bits with the same polarity.

After each sequence of 5 identical bits, the block transmitter adds one bit with the opposite polarity to the bit stream.

Receiver units clear these bits after receiving a message on the CAN data bus.

Troubleshooting

If any CAN data bus module detects an error, it will abort the current data transfer process by sending an error message. The error message consists of 6 dominant bits.

Thanks to the error message, all control units connected to the CAN data bus are notified of a local error that has occurred and accordingly ignore the previously transmitted message.

After a short pause, all control units will again be able to transmit messages on the CAN data bus, with the message with the highest priority again being sent first.

The control unit, whose message on the CAN data bus caused the error, also starts retransmitting its message (Automatic Repeat Request function).

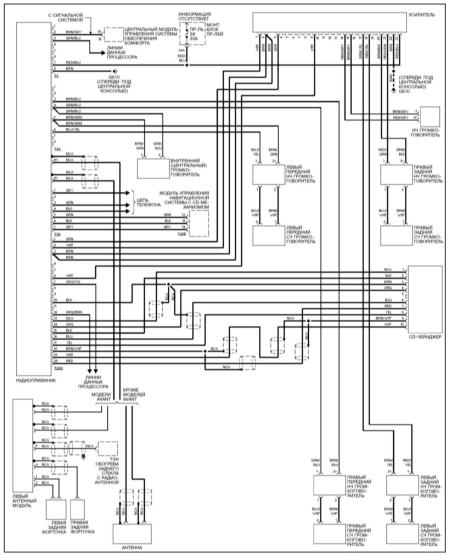

CAN bus types

Different CAN buses are used for different control areas. They differ from each other in data transfer speed.

The transmission rate on the CAN data bus in the area "engine and chassis" (CAN-C) is 125 kbit/s, while the data bus data bus "interior" (CAN-B) is only designed for a data transfer rate of 83 kbit due to the lower number of particularly urgent messages /With.

Communication between the two bus systems takes place via so-called "gateways", i.e. control units connected to both data buses.

Fiber optic data bus D2B (Digital Daten-Bus) is used for the field "Audio/Communication/Navigation". An optical fiber cable can transmit a significantly larger amount of information than a bus with a copper cable.

Retrieved from http://carmanz.com/audi/a4-b6-2000-2004/6717-a4200012-35.html

![B6 [2000 - 2005]](/uploads/Audi_A4_2000-2005_B6_.jpg)