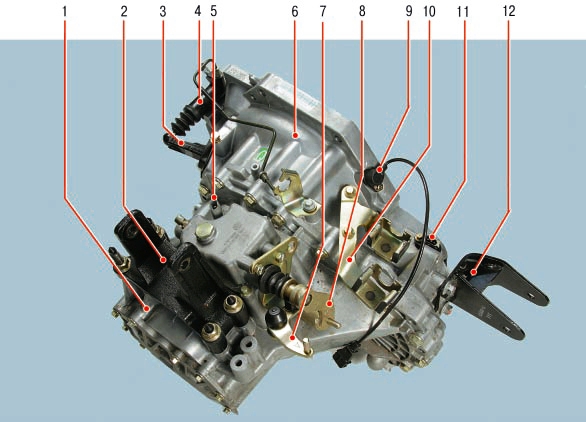

Manual Transmission:

1 - gearbox housing;

2 – an arm of the left support of the power unit;

3 - clutch release fork;

4 – the working cylinder of a drive of deenergizing of coupling;

5 - reverse light switch;

6 - clutch housing;

7 - gear selection lever;

8 - gear lever;

9 - engine crankshaft position sensor;

10 – an arm of fastening of cables of management by a transmission;

11 – speed sensor;

12 - bracket for the rear support of the power unit.

Chery Tiggo cars are equipped with mechanical gearboxes such as QR523MHC (with SQR481FC engine), QR523MHB (with 4G63 and 4G64 engines and single axle drive) and QR523T (with 4G64 engine and all-wheel drive). Gearboxes differ in the design of individual parts, but have a fundamentally common layout and installation dimensions.

The gearbox is made according to a two-shaft scheme with five synchronized forward gears. The gearbox and final drive with differential have a common crankcase - 1 . A crankcase - 6 clutch is attached to the front of the gearbox housing . The rear of the gearbox housing is closed with a molded cover.

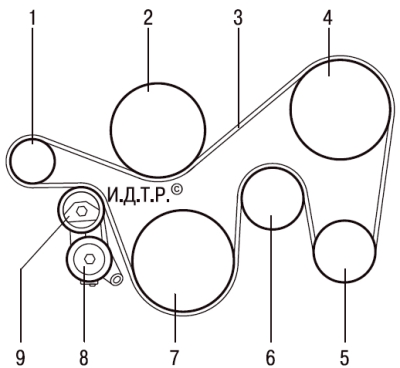

The input shaft is made in one piece with the drive gears of I-II gears. In addition, the 5th gear fixed on the splines of the shaft and the drive gears of the 3rd–4th gears with synchronizers freely rotating on needle bearings are located on the shaft.

The output shaft is made in one piece with the final drive gear. The driven gears of I–II gears, III–IV gears and V gears, freely rotating on needle bearings, are also installed on the secondary shaft.

The forward gears are switched on by axial movement of the gear synchronizer clutches. The gearshift mechanism is located inside the gearbox housing on its left side. Outside there are two levers of the mechanism: a lever - 7 gear selection and a lever - 8 shifts.

The manual transmission control drive consists of a gear lever link with a ball bearing mounted on the base of the body, two shift and gear selection cables, as well as a mechanism installed in the gearbox housing. To ensure a clear engagement of gears, the lever - 8 gear shift of the shift mechanism is made in one piece with a massive counterweight. The gear selection and shift cables are structurally different from each other and are not interchangeable.

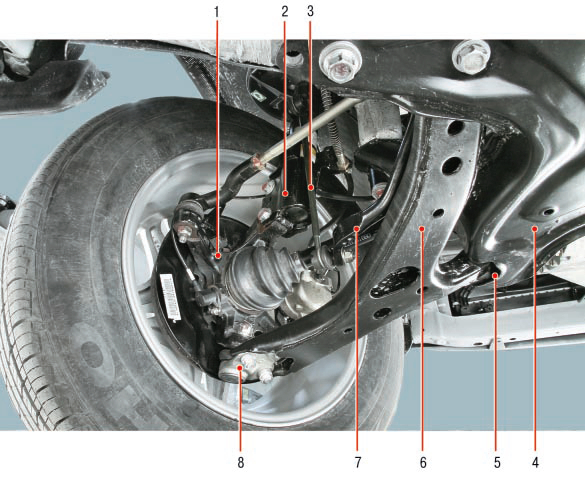

The main gear is made in the form of a pair of cylindrical gears matched according to noise. Torque is transmitted from the driven gear of the final drive to the differential and then to the front wheel drives.

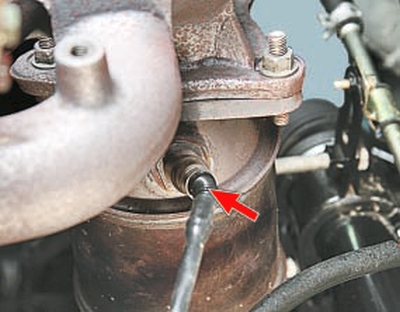

The differential is conical, two-satellite. The tightness of the connection of the internal hinges of the front wheel drives with the differential gears is ensured by oil seals.

To repair a gearbox, a large set of special tools and appropriate training of the performer are required, therefore, in this section, only the processes of removing and installing the gearbox, replacing its seals and repairing the drive are considered. To repair the gearbox, contact a specialized service.

Source: http://chery-tiggo.dv13.ru/korobka-peredach/

![T11 [2005 - 2014]](/uploads/Chery_Tigo_T11_2005_-_2014_.jpg)