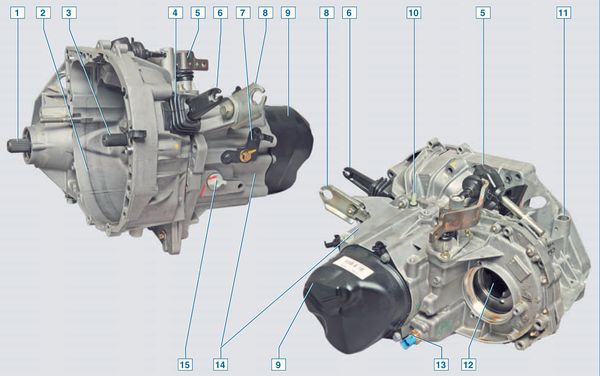

Gearbox :

1 - differential side gear shaft;

2 - clutch housing;

3 - input shaft;

4 — mud-protective cover; 5 - gear shift mechanism;

6 — a plug of a drive of deenergizing of coupling;

7 - holder of wiring harnesses;

8 - bracket for the cable sheath of the clutch release drive;

9 - back cover;

10 - breather hose fitting;

11 - hole for the vehicle speed sensor;

12 - housing of the inner hinge of the left wheel drive;

13 - reverse light switch;

14 - gearbox housing;

15 - oil filler plug

Two types of manual transmissions are installed on Renault Logan cars: with a 1.4-liter engine - JH1, with a 1.6-liter engine - JH3. The marking is on the bottom of the gearbox housing. By design, both gearboxes are identical and differ only in the size of the clutch housing. The gear ratios of both gearboxes are the same.

Gearbox - two-shaft, with five forward gears and one reverse gear, with synchronizers in all forward gears. It is structurally integrated with the differential and final drive.

The gearbox housing consists of three parts: the clutch housing, the gearbox housing and the rear gearbox housing cover. The clutch housing and gearbox housing are cast aluminum alloy, and the back cover is steel stamped. The clutch housing is attached to the gearbox housing with screws. When assembling, a gasoline-oil-resistant sealant-gasket is applied between them. The back cover is attached to the crankcase with three bolts.

The input shaft is made as a block of driving gears, which are in constant engagement with the driven gears of all forward gears. The gears of all forward gears are helical, and the reverse gears are spur gears. Gears of 1-4 gears are made integral with the input shaft, the gear of the fifth gear rotates freely on the shaft. A fifth gear synchronizer is installed at the rear end of the input shaft. The output shaft is hollow, oil is supplied through it under the driven gears. The driven gears and synchronizers of 1-2 and 3-4 gears are located on the shaft. The fifth gear is mounted on the shaft with splines. On the side of the clutch housing, the bearing of the secondary shaft is roller, and on the side of the cover, it is ball bearing. An oil sump is located under the roller bearing of the secondary shaft, directing the flow of oil into the shaft. All parts mounted on the output shaft

The final drive gear is pressed onto the differential box. Behind the driven gear, a tapered roller bearing is installed on the differential box. Between the driven gear and the bearing, an adjusting ring is installed, the selection of the thickness of which regulates the preload in the differential bearings.

On the other (right) side, the differential box is equipped with a vehicle speed sensor drive gear and a second tapered roller bearing.

The differential box has two satellites and two side gears. The satellites are mounted on an axle fixed in the differential box.

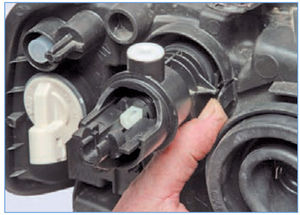

The right semi-axial gear of the differential is made integral with the splined shaft, on which the inner hinge of the right wheel drive is put on. An oil seal pressed into the socket of the clutch housing runs along the cylindrical surface of the shaft. The left semi-axial gear is made on the body of the inner hinge of the left wheel drive, and the body is installed in the gearbox socket and secured in it with a retaining ring. In order to avoid oil leakage from the gearbox, the connection of the inner joint of the left wheel drive with the gearbox housing is sealed with a rubber boot, which is attached to the gearbox housing with a metal holder. The other side of the cover is attached to the outer ring of the needle bearing mounted on the left wheel drive shaft. The needle bearing is integral with the oil seal,

To prevent water ingress and reduce dust ingress into the gearbox cavity, its breather is placed in the upper part of the engine compartment. The breather is connected by a rubber hose to the plastic fitting of the gearbox.

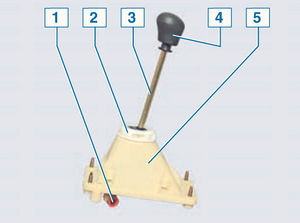

Control mechanism :

1 - sleeve;

2 - lever lock;

3 - gearshift lever;

4 - lever handle;

5 - mechanism case

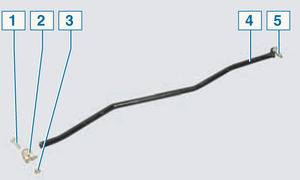

Control rod :

1 - coupling bolt;

2 - clamp;

3 - nut;

4 - thrust;

5 — a finger of draft

The drive of management of a transmission consists of the control mechanism, draft of management and the mechanism of a gear change. A ball joint is installed on the gear lever, which is inserted into the plastic housing of the control mechanism and secured with a retainer. A sleeve is welded to the lower end of the lever, to which the control rod is attached. The other end of the control rod is connected to the gearshift mechanism mounted on the gearbox.

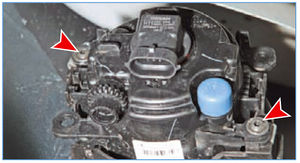

The gearbox is factory-filled with gear oil designed to last the life of the vehicle. The oil level in the gearbox should be at the level of the lower edge of the filler hole. The filler hole is located in the gearbox housing, in front of the vehicle. The plastic filler plug is made in such a way that it can be unscrewed and wrapped by hand, without the use of any tool. The cork is sealed with a rubber ring. The drain hole is located on the bottom of the gearbox housing. The drain plug is sealed with a copper washer.

Source: http://wiki.zr.ru/KPP_114_Remont_Logan_2005

![1 generation [2004 - 2013]](/uploads/Renault_Logan_2004-2009_.jpg)

![2 generation [2013 - 2021]](/uploads/Renault_Logan_2013-2015_.jpg)