If the engine does not start, analyze the situation. For a gasoline engine to start at all, two basic conditions must be met. A fuel-air mixture should flow into the cylinders, and a spark should be generated at the spark plug. Therefore, firstly, you should check if fuel is being supplied.

To determine if a spark is being produced, the candles should be unscrewed, inserted into the tips and individually applied to the mass. When doing this, do not hold the tip or ignition cable with your hands, but use well-insulated tongs. Have an assistant start the engine.

Engine start

All engines

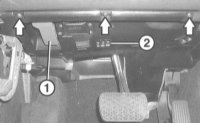

- Manual transmission: Apply the parking brake, fully depress the clutch pedal and hold it. Set the gearbox to neutral. The disengaged clutch makes it easier to start the engine, especially at low outside temperatures, because. while there is no friction from the gearbox.

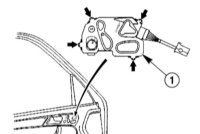

- Automatic transmission: Set the selector to "P" or "N". Press the brake pedal and hold it.

|

Do not turn on the starter for more than 30 seconds continuously, otherwise the starter and cables will overheat. |

Gasoline engine

· Turn the ignition key and turn on the starter without giving gas. Release the key as soon as the engine starts. If the engine does not start within 5 seconds, depress the accelerator pedal slightly and start again. If the engine does not start or immediately stops, repeat the start with the accelerator pedal half depressed, and if necessary, another start with the accelerator pedal fully depressed.

With a hot engine, depress the gas pedal slowly during starting.

· Be sure to immediately start driving, only in severe frost, let the engine warm up for 30 seconds.

|

Unsuccessful, successive attempts to start the engine can harm the catalytic converter, because. unburned gasoline gets into it and explodes when heated. |

Diesel engine

- On a cold engine: Switch on the ignition and wait until the preheat indicator lamp goes out. Immediately after the control lamp has gone out, start the engine without giving gas. If irregular flashes occur during start-up, keep the starter turned on until (but not more than 20 seconds) until the engine starts to work on its own. If the engine still does not start, turn the ignition key to position "0" and wait approximately 30 seconds. After that, pre-heat again and repeat the start-up as described above.

|

While preheating is being done, powerful electrical consumers should not be turned on, otherwise the battery will be overloaded unnecessarily. |

|

A direct injection diesel engine generally requires preheating only at temperatures below 0°C. |

- Preheating is not required on a warm engine. Start the engine immediately without giving gas.

The engine does not turn over when trying to start it

1. The battery terminals are corroded or the wire lugs are loose. Check the condition of the terminals and lugs. Tighten the terminal clamps, if necessary, remove traces of corrosion.

2. Discharged or defective battery. If the wire lugs are found clean and securely attached to the battery terminals, turn the ignition key to the ON position, then turn on the headlights and/or windshield wipers. If this electrical equipment does not function, the battery is dead.

3. The transmission is not correctly set to the “P” position.

4. The wiring in the starting system circuit is broken or the wires are loose on the terminals. Check the condition of the wires, terminals and electrical connectors of the battery, the starter traction relay and the ignition switch.

5. The starter gear is wedged in the ring gear of the drive disk. Try to crank the engine by the crankshaft pulley. At the first opportunity, remove the starter and check the condition of the gear and ring gear.

6. Defective starter relay.

7. Faulty starter.

8. Faulty ignition lock.

Engine cranks but does not start

1. Starting is not correct.

2. Faulty or not disabled engine immobilizer.

3. Faulty fuse:

- Electric fuel pump;

- Electronic injection system.

4. Empty fuel tank or poor quality fuel.

5. The air filter is very dirty. There are vacuum leaks in the air supply elements, malfunctions in the fuel injection and ignition control system.

6. Low battery (engine cranks too slowly). Check the functioning of the electrical equipment.

7. Battery terminal connections are corroded or loose.

8. The fuel pump is faulty, its fuse is blown, or the pump relay is damaged. Check up on hearing noise of work of the pump at inclusion of ignition .

9. Damaged or excessively wet components of the ignition system.

10. Worn or defective spark plugs or incorrect spark plug gap.

11. Broken or disconnected wiring of the electric circuit of the starting system or loosened fastening of the wires to the terminals.

12. Broken or disconnected ignition coil circuit wiring or loose wires at coil terminals.

13. The fuse of the engine control unit is damaged, any of the sensors is faulty: Hall, pulse sensor, coolant temperature sensor or intake air.

14. Compression pressure too low. Replace the cylinder head gasket. Repair the engine if necessary.

Diesel engine:

1. Wrong start.

2. Faulty engine immobilizer.

3. The fuse is faulty:

Electric fuel pump;

· Preheating systems.

4. The engine is not warmed up: check the correct functioning of the preheater.

5. There is no voltage at the solenoid shut-off valve. Connect a voltmeter or LED probe to the switch. Turn on the ignition. The LED should light up. Otherwise, you need to find a break in the wiring and fix it.

6. Faulty solenoid shut-off valve. Check the reliability of the fastening of the electromagnetic switch, check the contacts. Turn the ignition on and off. The switch should click.

7. There is damage in the fuel supply line or air in the lines:

a) Piping or hoses are mechanically damaged or clogged. Clean fuel lines and bleed air from lines and filter.

b) Fuel filter clogged. Replace filter element.

c) In winter, the filter and piping should be checked for ice or wax. Put the car in a heated garage, add gasoline to the system.

d) Clogged tank vent or fuel inlet strainer. Clean out.

8. The adjustment of the start of the fuel supply is knocked down. Check, make adjustments.

9. Faulty nozzles. Check. Loosen the union nuts in sequence - when the nut of the faulty cylinder is unscrewed, the engine speed will not drop.

10. The high pressure fuel pump (TNVD) is faulty. Install a new or known-good injection pump for testing.

11. Compression pressure too low. Replace the cylinder head gasket. Repair the engine if necessary.

The starter operates without cranking the engine

1. The starter gear is jammed. Remove the starter and check its condition.

2. Worn or damaged starter gear teeth or flywheel crown.

Difficulty starting a cold engine

1. Discharged or insufficiently charged battery.

2. There is a malfunction of a component of the power system or electrical equipment.

3. Paraffin in the diesel engine fine filter. Replace filter element. Fill with winter fuel, or dilute with low-octane gasoline.

4. Faulty diesel engine glow plugs.

Difficulty starting hot engine

1. Blocked air filter.

2. There is a malfunction of a component of the power system or electrical equipment.

3. Fuel does not reach the injectors of the injection system.

4. The fuel advance angle of the diesel engine has gone astray.

5. Low compression in the cylinders, the injection pump of the diesel engine is faulty or misadjusted.

Starter engagement is too noisy or difficult

1. Starter gear teeth or flywheel ring are worn or damaged.

2. Lost starter mounting bolts or weakened their tightening force.

Engine starts but stalls immediately

1. Faulty engine immobilizer.

2. Faulty wiring or loose wires at the coil or generator terminals.

3. There is a malfunction of a component of the power system or electrical equipment.

4. The basic settings of the electronic control unit (ECM) are violated.

5. Damage to the exhaust system/catalytic converter.

6. Vacuum loss occurs through the sealing surfaces of the intake manifold or fuel injection unit. Make sure that the fixing bolts/nuts are securely tightened, check the fact and quality of fastening on your fittings on the inlet pipeline of all vacuum hoses. Check the condition of the hoses and the correctness of their connection (exactly to their fittings).

Source: http://www.auto-knigi.com/model/mb_c/1_8/

![W203/S203/CL203 [2000 - 2004]](/uploads/mercedes-c-klass-w203.jpg)