Tools:

- screw jack

- balloon wrench

- Screwdriver flat medium

- Ratchet wrench

- Extension (with cardan)

- Head 10 mm

- Head 12 mm

- Straight ring wrench 16 mm

- Marker

- Hex wrench for fixing the tensioner (or pin)

Parts and consumables:

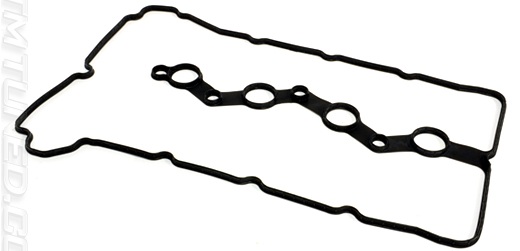

- Auxiliary drive belt (5750.YT - for 4B12 engine or 5750.VX - for 4HN engine)

- Auxiliary drive belt tensioner (5751.G5 - for 4B12 engine or 5751.G0 - for 4HN engine)

- wheel chock

Notes:

The Crosser engine is equipped with attachments, which are driven by a single drive belt.

The accessory drive belt does not require tension adjustment during its entire service life, as it has an automatic tensioner in its design. If, due to excessive wear or stretching of the belt, the tensioner is not able to maintain its normal tension, the belt is replaced.

Belt inspection and replacement operations are shown on the 4B12 engine. Work on a diesel engine is almost the same (difference in tool sizes).

Checking the tension of the accessory drive belt

1. Check the condition of the belt by visual inspection. If the belt shows signs of severe wear (disappearance of two or more adjacent ribs of streams in a section longer than 13 mm), longitudinal or transverse cracks, rubber peeling or oiling of the belt, the auxiliary belt must be replaced.

Note:

An additional sign of the need to replace the accessory drive belt is a characteristic whistle (belt slip).

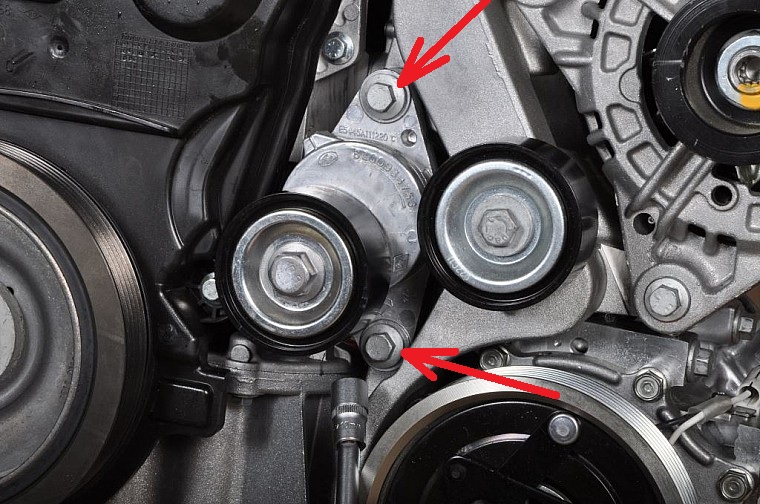

2. There are marks on the tensioner and bracket. Make sure that the accessory drive belt tensioner mark is within the allowable range (in the photo below, the range is indicated by the red zone).

Accessory drive belt replacement

Note:

If the accessory drive belt is to be reused, mark an arrow on the back (non-working) side of the belt with a marker to indicate the direction of rotation in a clockwise direction.

1. Apply the parking brake and place a wheel chock under the left rear wheel. Use a wheel wrench to loosen the right front wheel nuts 1 turn, and then use a jack to hang the right front of the car and completely unscrew the wheel nuts to remove the wheel.

2. Then remove the mudguards (rear, front, lower and right side) of the engine using a screwdriver and a 10 mm socket.

3. Remove the mounting bolt, then move the expansion tank of the cooling system, together with the connected hose, to a position where it will not interfere with the removal and installation of the accessory drive belt.

Note:

Removal of the reservoir of the cooling system is carried out without removing the coolant from it and the cooling system.

4. Turn the tensioner counterclockwise (45° angle) with a wrench until the belt tension is loosened and the holes on the tensioner match.

5. Lock the tensioner with a pin or hex wrench (shown on the removed tensioner for clarity).

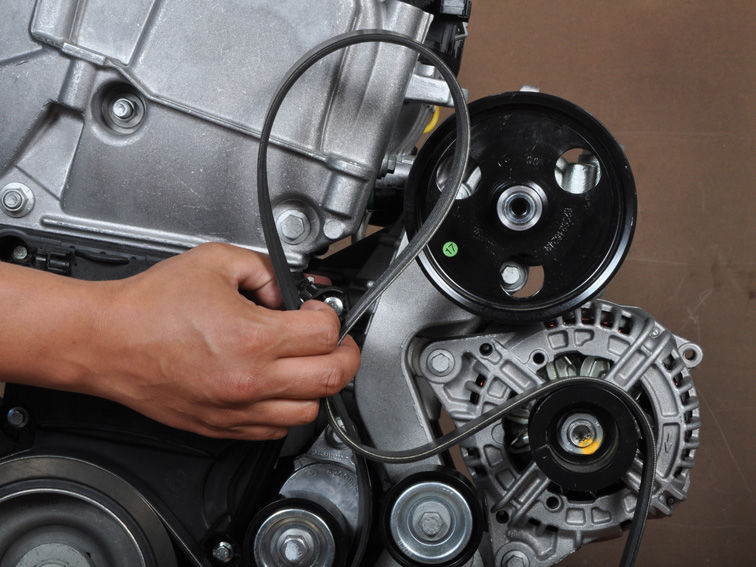

6. Remove the accessory drive belt from the tension roller and completely remove the belt from the engine compartment.

7. Replacement of the tension roller of the drive belt is assembled with an automatic tensioner. To remove the tensioner, unscrew the two mounting bolts and remove it.

8. Install a new accessory drive belt and all removed parts in the reverse order of removal.

9. Rotate the crankshaft three full revolutions per wheel (in 5th gear) to get the accessory drive belt in the correct position on the pulleys.

The article is missing:

- Tool photo

- Photo of parts and consumables

Source: carpedia.club

![1 generation [2007 - 2013]](/uploads/Citroen_C-Crosser_2007_-_2013_.jpg)