Tools:

- Jack

- Support legs

- torque wrench

Parts and consumables:

- High pressure flexible hoses

- Syringe

- Dye

- brake fluid bottle

- Brake fluid

- Bearing grease

- Wheel bolts

Observe the rules for handling brake fluid.

The pipelines of the brake system communicate the master brake cylinder with the four wheel cylinders. The connection between the rigid and moving parts of the brake system, for example, between the calipers, is carried out by flexible high-pressure hoses. If there is visible damage, the latter must be replaced.

Notes:

Do not allow brake hoses to come into contact with oil or fuel, and do not paint or coat them with an underbody anti-corrosion agent.

If one of the chambers of the brake fluid reservoir is completely emptied (for example, if there is a leak in the brake system or if you forgot to add fluid to the reservoir when bleeding air), air is drawn into the system and enters the ABS pump. In this case, the air from the brake system must be removed at the service station using a special device.

Withdrawal

1. Suck the brake fluid out of the reservoir with a syringe.

2. Mark with paint the position of the wheels relative to the hubs. This will allow the assembly to install the balanced wheels in their original position. Loosen the wheel bolts before jacking up the vehicle. Raise the car, put it on stands and remove the wheels.

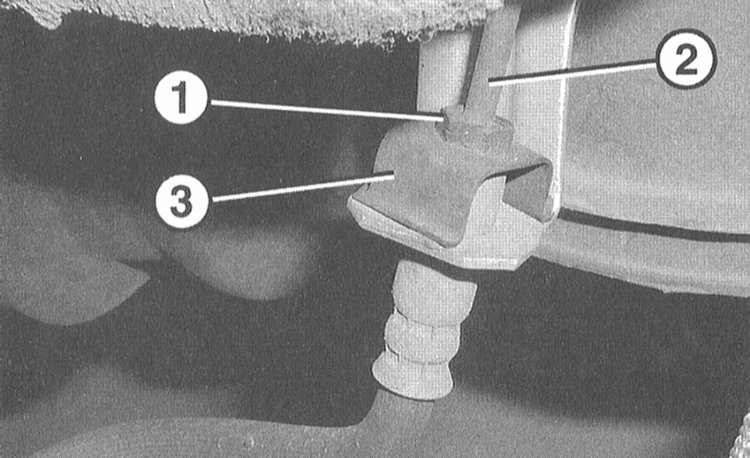

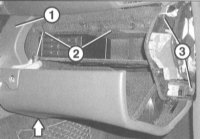

3. Turn out a hollow bolt and disconnect the brake pipeline from a hose.

1 - bolt;

2 - brake pipeline;

3 - bracket.

Notes:

The brake hose must not be twisted.

4. Remove the bracket and remove the hose from the holder.

5. Plug the brake pipe and hose immediately.

Notes:

When the brake circuit is opened, brake fluid flows out. Drain it into a bottle, which should be designed exclusively for this purpose. You can first suck out the liquid from the reservoir using a special device.

6. Front wheel brake: Remove the brake hose from the holder on the suspension strut.

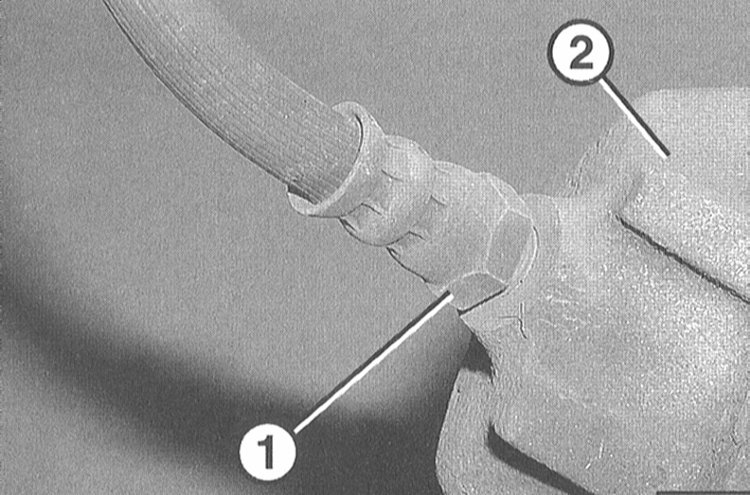

7. Turn out a brake hose from a support.

1 - hose;

2 - support.

Notes:

Brake fluid flows out of the caliper connection hole. Take precautions.

Installation

1. Fasten the brake hose to the caliper with a torque of 18Nm.

2. Front wheel brake: Pull the hose through the holder on the shock strut.

3. Fix the hose in the holders and insert it into the retaining clip. Screw the hollow bolt of the brake pipe into the hose connector and tighten with a torque of 14Nm.

Notes:

Do not twist the brake hose.

4. Bleeding the brake system, refer to the relevant section .

5. After removing air from the brake system, fill the reservoir with liquid to the MAX mark and screw on the cap.

6. Reinstall the wheels so that the marks made during removal match. Pre-lubricate with a thin layer of bearing grease the centering belt of the wheel disk on the hub. Do not grease wheel bolts. Replace rusty bolts. Wrap bolts. Lower the car onto the wheels and tighten the bolts crosswise to 110Nm.

Notes:

The brake hose, when the steering wheel is fully turned to the right and left, as well as when raising and lowering the vehicle on shock absorbers, must not touch any suspension elements. In any traffic situation, the hose must be at a sufficient distance from adjacent structures.

Check reliability:

- Are the brake hoses fixed?

- is the brake hose fixed in the holder;

- Are the air bleed fittings tight?

- whether a sufficient amount of brake fluid is filled;

- with the engine running, check for leaks. To do this, press the brake pedal with a force of 200 - 300 N (20 - 30 kg) for 10 s. The pedal must not loosen. Check all connections for tightness.

7. Check the operation of the brake system on a road with light traffic. To do this, it is necessary to apply at least one hard braking using the ABS action (felt by the pulsation of the brake pedal).

The article is missing:

- Tool photo

- Photo of parts and consumables

- High-quality repair photos

Source: http://www.auto-knigi.com/model/mb_c/11_13

![W203/S203/CL203 [2000 - 2004]](/uploads/mercedes-c-klass-w203.jpg)