The Skoda automatic transmission is arranged according to the traditional planetary circuit with friction braking, connected to the engine crankshaft through a torque converter and includes the following elements and systems.

The torque converter corresponds to the clutch in a manual transmission, but does not require direct control from the driver. The torque converter is used to transfer torque from the engine to the automatic transmission. During operation, this assembly, filled with a working fluid, carries heavy loads and rotates at high speed. It not only transmits torque, absorbs and smoothes engine vibrations, but also drives the hydraulic fluid pump located in the gearbox housing. The pump fills the torque converter with working fluid and creates working pressure in the control and monitoring system.

Planetary gear sets correspond to the gear set in a manual transmission

and serve to change the gear ratio in an automatic transmission when shifting gears.

The automatic transmission hydraulic control system includes a pump, pressure regulator, automatic transmission range selection spool valve, auxiliary valves (solenoids), clutches and brakes.

The pump creates pressure in the system, ensuring the operation of the torque converter, lock-up clutches, brakes and lubrication of the gearbox parts. The pressure generated by the pump is adjusted according to vehicle speed and engine load. The pump is driven from the crankshaft of the engine.

Band brakes are used to temporarily block the elements of the corresponding planetary gear set on the automatic transmission housing.

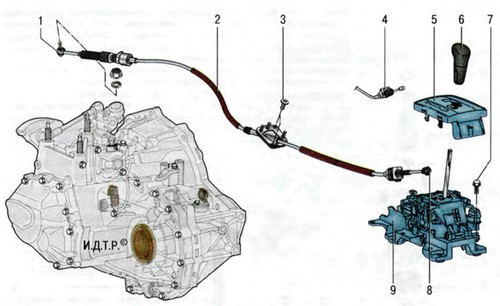

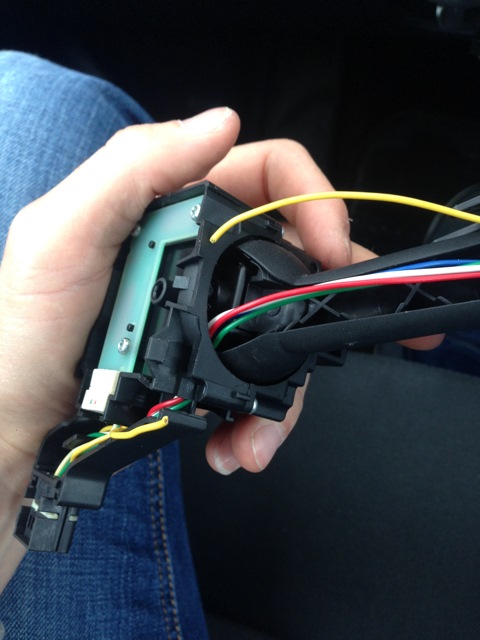

The selector for selecting automatic transmission modes (Fig. 743) is installed on the floor tunnel and connected to the control unit on the gearbox with a cable. In addition to the control cable, a lock cable is attached to the selector, which does not allow the key to be removed from the ignition lock if the selector lever is not set to the “P” (parking) position.

Rice. 743. Automatic transmission control drive:

1 - tip of the control cable (gearbox side); 2 - control cable; 3 - screw; 4 - tip of the ignition key blocking cable; 5 - selector panel; 6 - handle of the variator selector lever; 7 - bolt; 8 - tip of the control cable (side of the selector lever); 9 - gearbox control selector mechanism.

Automatic transmission diagnostics. There are several operations and tests for earlier and more accurate fault detection. However, we recommend that you do not abuse them and observe safety measures in order to avoid breakdowns. If the test results on the car are in doubt, it is better to contact specialists.

The simplest is the time delay test. It consists in the fact that during engine idling, when the drive mode selector lever is set to the "D" or "R" position from the neutral position "N", there must be a time delay before operation is felt. The purpose of this test is to check the performance of the components and mechanisms of the gearbox.

For safety reasons and to prevent damage, you must:

- before carrying out the test, warm up the gearbox well, the automatic transmission temperature should be at least 50-80 °C;

- to achieve a high quality check, perform at least three measurements and determine their average value;

- to maintain a high performance of the automatic transmission, take a break of 1 min between measurements.

The time delay test is carried out as follows.

1. Fully raise the parking brake lever.

2. Start the engine.

3. Check the idling speed in the "N" range. The idle speed should be 750-900 min^-1. If the engine speed is not correct, then the measurement results will also be incorrect and the test will have to be repeated.

4. Move the driving mode selector lever from the "N" position to the "D" position.

5. Using a stopwatch, measure the time from starting to move the handle until the transmission engages. Measurements are recommended to be carried out at least three times and their average value determined. In this case, the time delay should be no more than 1.2 s.

6. Using the same method, take measurements when shifting from the "N" position to the "R" position. In this case, the time delay should not be more than 1.5 s.

When evaluating the results of the test, you must proceed from the fact that in the presence of any breakdown, the response time can only increase. Only a specialist can find out the cause and eliminate the malfunction, so contact the service center immediately.

Pretty simple and parking test. Its purpose is to check the performance of the engine, torque converter and gearbox as a whole.

To ensure safety and avoid breakdowns:

- it is necessary to carry out the test on a sufficiently bright and wide area;

- the test must be carried out by two masters working in pairs: one of them observes the wheels and their stops and immediately warns about turning the wheels or displacement of the stops, the second one conducts tests and records measurements;

- the duration of the test should not exceed 5 s.

Carry out the test and evaluate its results in the following order.

1. Be sure to secure the front and rear wheels of the car.

2. If necessary, install a tachometer.

3. Apply the parking brake.

4. Press the brake pedal with your left foot and hold it in this position throughout the test.

5. Start the engine.

6. Set the driving mode select lever to range "D".

7. Pressing the gas pedal with your right foot all the way, measure the tachometer readings.

8. Take a break of at least 1 minute.

Repeat the test with the driving mode select lever in the "R" range. When evaluating this test, you need to know that with each press on the gas pedal, the tachometer needle should smoothly rise and stop within 2400-2700 min ^ -1. In this case, there should not be any extraneous noise, vibration and shock, and the car should remain in place. If the tachometer reading:

- less than the norm, but the same in both ranges ("D" and "R"), then most often the reason lies in insufficient engine power;

- above the norm in both ranges, then the reason is most likely a malfunction of the torque converter or gearbox;

- above the norm in one of the ranges, probably a malfunction only in the gearbox.

The most difficult to conduct and evaluate is a road test, which serves to determine shift points, detect extraneous noise, vibration and slip in the gearbox.

To ensure safety, the test should be carried out on a sufficiently wide, level and empty section of the road; warm up the engine and gearbox well before driving.

Conduct a road test and evaluate its results as follows.

1. Set the driving mode selection lever to position “D” and, gradually pressing the gas pedal, check for the presence of shifts of I-II, II-Sh, III-IV and IV-V gears. If there is no any of the switching, then the automatic transmission or its control and monitoring unit is faulty; if the switching points are tightened, then the problem is most likely in the control system.

2. Fix the speed of 70 km / h in the "D" mode and slightly depress the gas pedal. The engine speed should not change abruptly. If a sharp jump in speed is observed on the tachometer, then it can be argued that there is a malfunction in the torque converter and it will soon completely fail.

3. Stop and move the driving mode selection lever 8 to the manual shift range. Gradually pressing a gas pedal, check up presence of switching 1-II. When moving in 2nd gear, release the accelerator pedal and note the presence of engine braking. Repeat this operation several times, make sure that the shifts I-II, II-I are not accompanied by vibration, shock or slippage. If there are no signs of a malfunction, the box is in good condition.

4. Come to a complete stop, move the lever to position "1" and, gently pressing the gas pedal, make sure that there is no switching to the second stage, and also check for engine braking when the gas pedal is released. While pressing and releasing the gas pedal repeatedly, listen to how the gearbox works to identify extraneous noises and vibrations. If there is a switch to the second stage or there is no engine braking, then the control and monitoring unit is faulty.

5. Stop and, switching to the "R" range, sharply press the gas pedal. After making sure that there are no slips, vibrations and extraneous noise, continue testing.

6. With the vehicle parked on an incline (approximately 5°), move the driving mode selector lever to the "P" position and release the brake. The vehicle must be securely locked in place. If the car rolls, then the cause should be sought in a malfunction of the box parking mechanism.

We remind you that during the test you need to pay special attention to the presence of third-party noise and vibration. Treat them with due responsibility, as vibrations can also be caused by an imbalance in the torque converter, drive shaft, etc., which can lead to a breakdown of the unit.

Source: http://skoda-octavia2.ru/index.php/transmissia/131-vozmozhnye-neispravnosti-korobki-peredach-i-sposoby-ikh-ustraneniya.html

![1 generation [restyling] [2000 - 2010]](/uploads/Skoda_Octavia_2000_-_2010_.jpg)

![2 generation [2004 - 2008]](/uploads/Skoda_Octavia_2004_-_2012_.jpg)

![3 generation [2013 - 2017]](/uploads/Skoda_Octavia_2013_-_2015_.jpg)