Tools:

- Open-end wrench - 10 mm

- Open-end wrench - 13 mm

- Open-end wrench - 22 mm

- Nozzle on the collar - 10

- Nozzle on the collar - 16

- Hex key - 5 mm

Parts and consumables:

- Timing belt

- Tension roller

- guide rollers

The timing belt should be replaced every 40 thousand kilometers or after 4 years.

Replace the timing belt if, upon inspection, you find:

1 - traces of oil on any surface of the belt;

2 - traces of wear of the serrated surface, cracks, undercuts, folds and delamination of the fabric from the rubber;

3 - cracks, folds, depressions or bulges on the outer surface of the belt;

4 - loosening or delamination on the end surfaces of the belt.

Warning:

A belt with traces of engine oil on any of its surfaces must be replaced, as oil quickly destroys rubber. The cause of oil getting on the belt (usually this is a violation of the tightness of the crankshaft and camshaft oil seals) must be eliminated immediately.

Carry out work on a viewing ditch, overpass or on a lift.

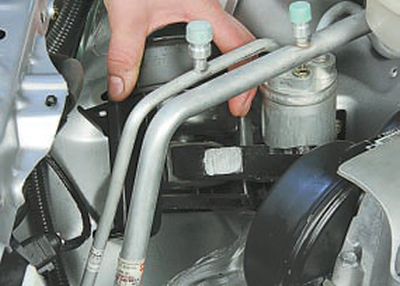

1. Remove the accessory drive belt. More details here .

2. Remove the right support of the power unit. More details here .

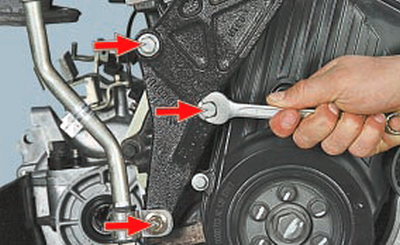

3. Turn out three bolts of fastening.

4. Remove the bracket for the right powertrain mount.

5. While holding the pulley from turning, use the second key to unscrew the six bolts securing the auxiliary drive pulley to the crankshaft hub, remove the pulley.

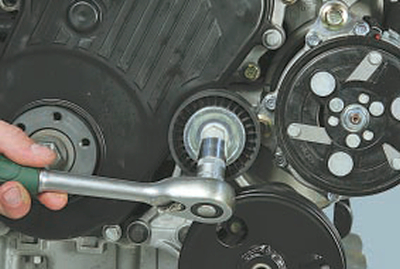

6. Turn out a bolt of fastening.

7. Remove the guide roller.

8. Turn out bolts of fastening of the top cover.

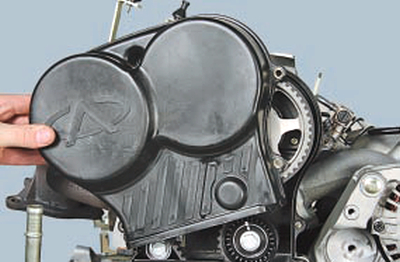

Note:

This is how the top cover bolts are located.

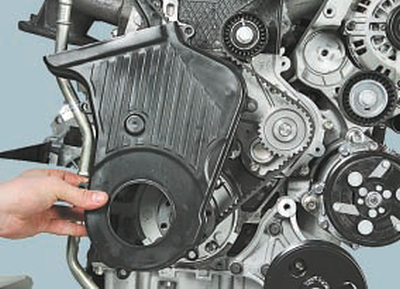

9. Remove the top cover of the gas distribution mechanism.

10. Turn out bolts of fastening of the bottom cover.

Note:

This is how the bottom cover screws are located.

11. Remove the bottom cover of the gas distribution mechanism.

12. Install the engine crankshaft in the service position. More details here .

13. Loosen the camshaft pulley bolts.

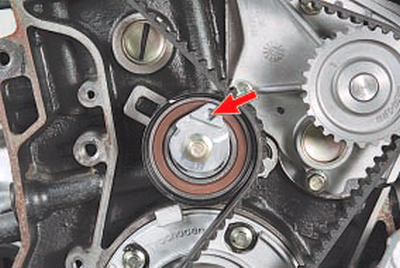

14. Loosen the tension roller bolt to loosen the timing belt tension.

15. Remove the belt.

16. To replace the tension roller, unscrew its fastening bolt and remove the roller.

17. Establish a new tension roller back, without tightening up to the end a bolt of its fastening.

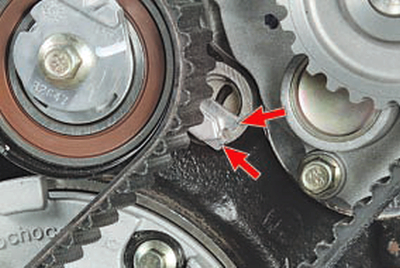

18. To replace the guide rollers of the gas distribution mechanism, unscrew the bolts of their fastening and remove the rollers.

19. Install new idlers in reverse order of removal.

20. Install the new timing belt back, first putting the belt on the crankshaft sprocket, and then on the water pump gear and camshaft pulleys.

Note:

Location of the timing belt.

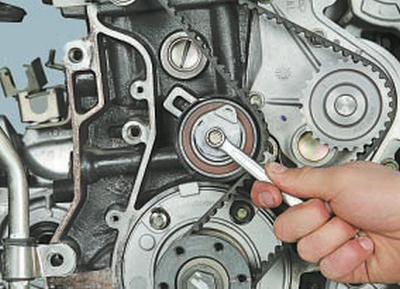

21. After installing the hex wrench and turning the eccentric of the tension roller, tighten the timing belt and finally tighten the tension roller mounting bolt.

Note:

Adjust the tension of the timing belt drive, controlling the degree of belt tension according to the tension roller indicators. In this case, the movable tension roller pointer will move counterclockwise towards the fixed pointer on the roller bracket. The belt is considered to be tensioned correctly if the pointers match. In this position, tighten the water pump mounting bolts.

22 . Check that the engine crankshaft is in the service position. More details here .

23. Install all removed parts in the reverse order of removal.

The article is missing:

- Tool photo

- Photo of parts and consumables

- High-quality repair photos

Source: http://chery-tiggo.dv13.ru/dvigatel/zamena-i-regulirovka-natyazheniya-remnya-privoda-gazoraspredelitelnogo-mexanizma/

![T11 [2005 - 2014]](/uploads/Chery_Tigo_T11_2005_-_2014_.jpg)