Tools:

- Screw jack

- Balloon wrench

- Adjustable support (or lifting device)

- Medium flat screwdriver

- Phillips screwdriver medium

- 6mm hexagon wrench

- 8mm hexagon wrench

- Ratchet wrench

- Extension (with cardan)

- 10 mm head

- 12 mm head

- 14 mm head (manufactured before 06.2008)

- Head 17 mm

- 17 mm straight spanner

- Torque wrench

- Marker

- Hexagonal special key for fixing the tensioner (or pin)

- Special hex key for fixing the tensioning mechanism (or pin d = 2 mm)

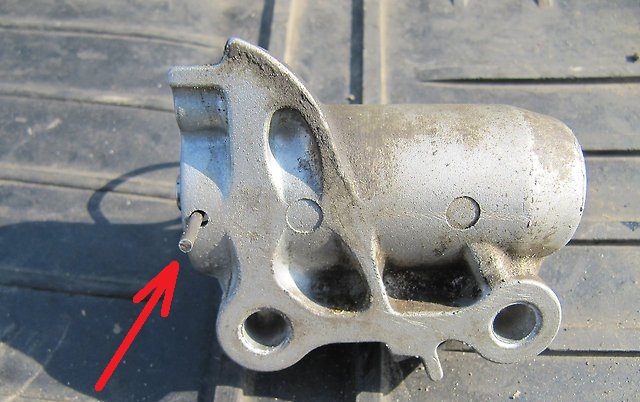

- Tool for fixing the crankshaft pulley (fork holder MB990767 and special bolts and MD998719)

- Knife (released from 07.2008)

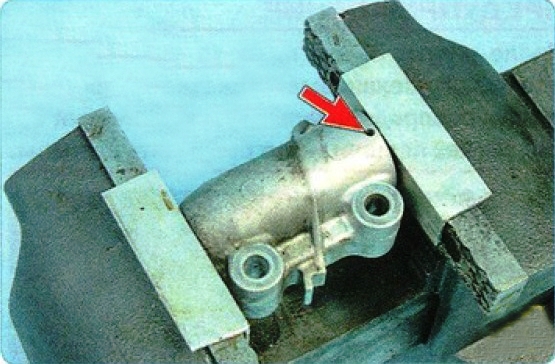

- Collar for end attachment

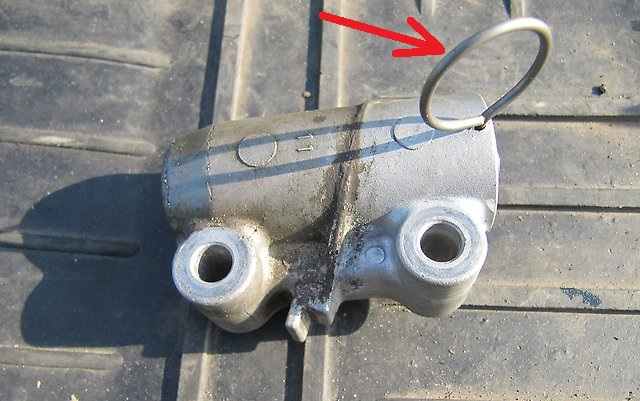

- Wrench attachment 22 mm

- Wheel chock (shoe)

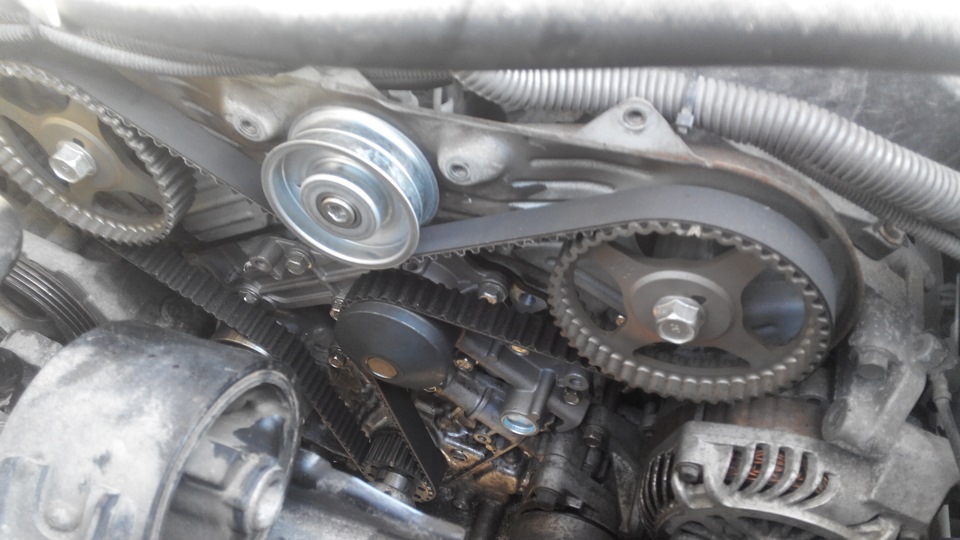

- Locksmith vices

- Calipers

Parts and consumables:

- Timing belt 1145A034

- Timing belt tensioner 1145A055

- Timing gear belt tensioner 1145A042

- Timing belt intermediate roller 1145A026

- Accessory drive belt 1340A132

- Power steering pump drive belt 4451A083 (release before 06.2008, if necessary)

- Power steering pump drive belt (4451A083) with belt installer 4451A086 (release from 07.2008, if necessary)

- Crankshaft pulley 1104A044 (if necessary)

- Wooden block (if necessary)

Notes:

According to the manufacturer's recommendation, the Outlander HL timing belt should be replaced after 90 thousand kilometers or 6 years of operation (whichever comes first). Also replace the belt if upon inspection you find:

- traces of oil on any surface of the belt;

- signs of wear on the toothed surface, cracks, undercuts, folds and peeling of fabric from rubber;

- cracks, folds, grooves or bulges on the outer surface of the belt;

- loosening of the cords or delamination on the end surfaces of the belt.

A belt with traces of engine oil on any of its surfaces must be replaced, as oil quickly destroys rubber. The cause of oil getting on the belt (usually a leakage of the crankshaft and camshaft oil seals) must be eliminated immediately.

Checking and replacing the timing belt of the engine Mitsubishi Outlander XL

1. Remove the decorative engine shroud as described here .

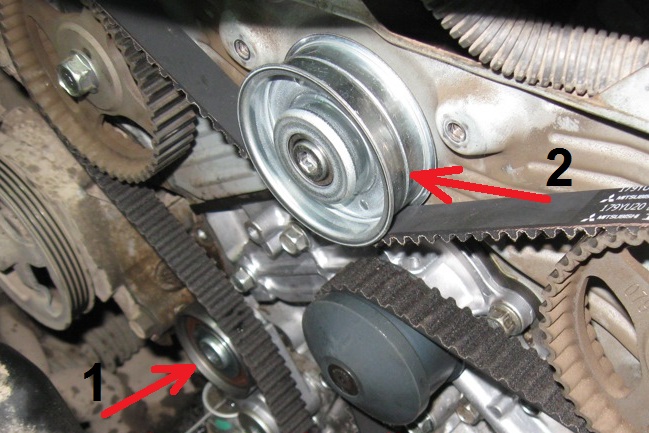

2. Remove the accessory drive belt 1 and the power steering pump 2 as described here .

3. Secure the Mitsubishi Outlander HL crankshaft pulley from turning using a special tool (fork holder and special bolts, k.n. MB990767 and MD998719, respectively).

Note:

To avoid damage to the crankshaft pulley damper, use only specified special tools for removal.

Secure the special tool securely so that it does not move.

4. With a knob with a 22 mm nozzle, unscrew the central bolt securing the crankshaft pulley and remove the bolt with washer.

5. Remove the crankshaft pulley and front dirt washer.

Note:

If the damper is damaged, the crankshaft pulley must be replaced.

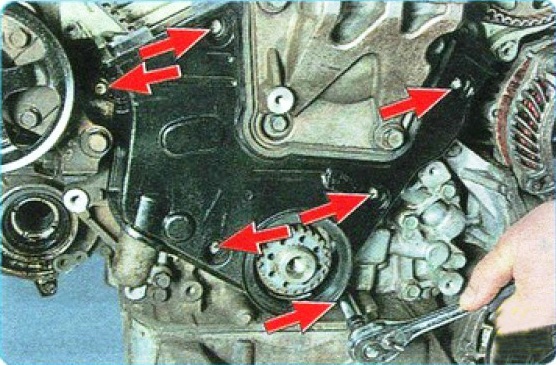

6. Remove the two upper parts of the timing belt cover as described here (items 5-6), and also remove the six bolts securing the lower part of the cover and remove it.

7. Remove the right engine mount as described in this article .

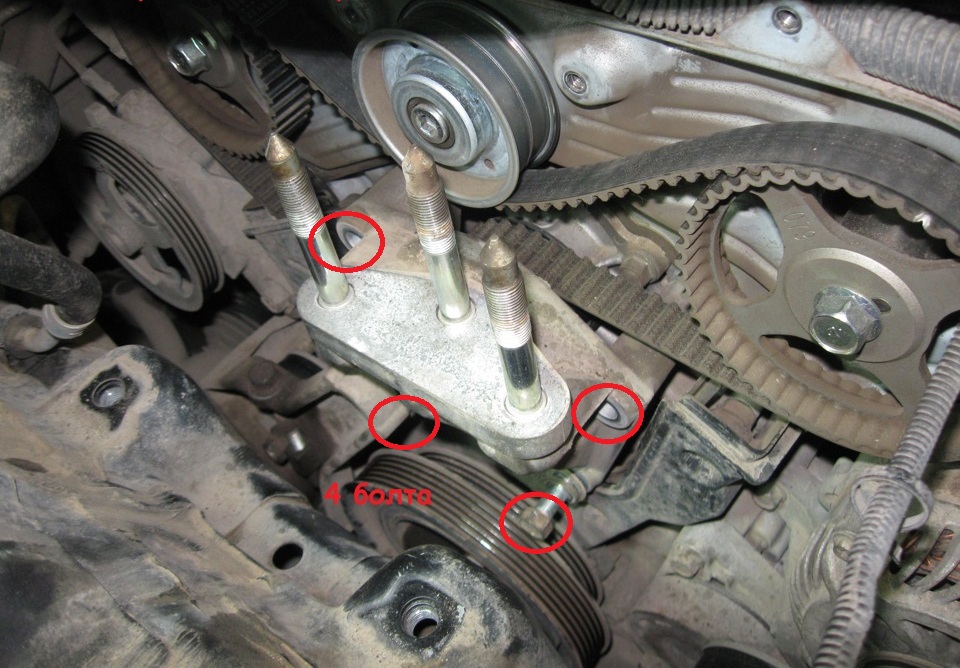

8. Then unscrew the four bolts securing the right engine mount bracket and remove it.

9. Screw the pulley mounting bolt into the crankshaft shank and set the 1st cylinder piston to TDC of the compression stroke as described here (paragraphs 7-8).

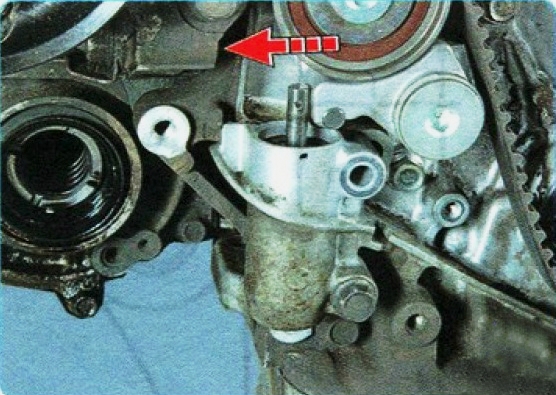

10. To loosen the belt, unscrew the belt tensioner mounting bolt and remove it from the hole in the tensioner housing.

11. After that, loosen the lower mounting bolt and slide the tensioner to the left. This will lower the tension roller and release the tension on the timing belt.

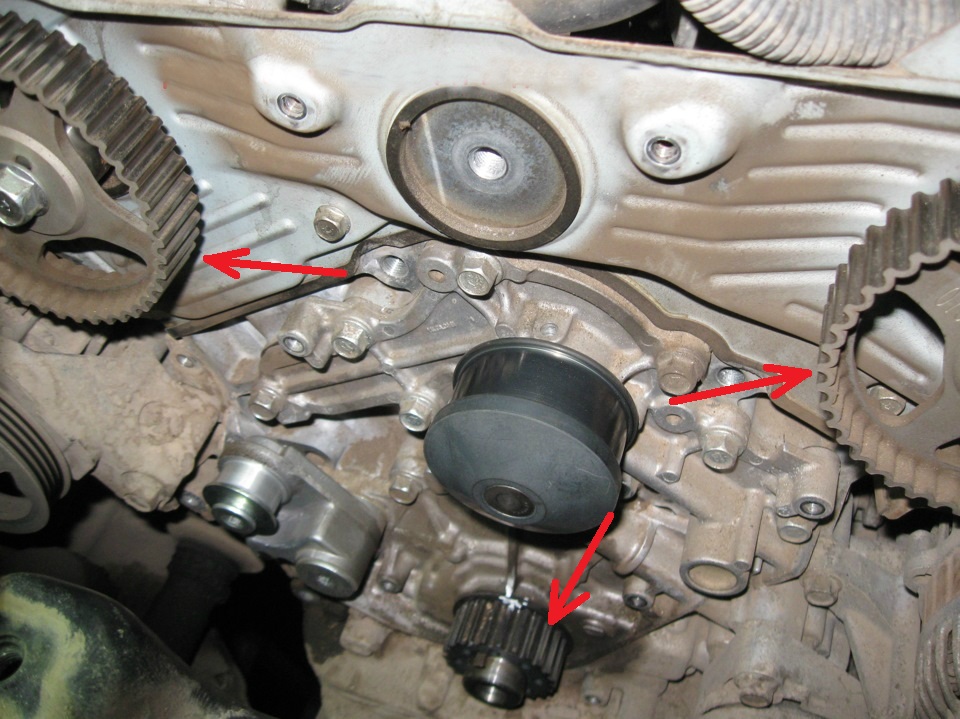

12. Remove the belt from the crankshaft toothed pulley, idler and idler rollers, and from the camshaft pulleys and the water pump.

Note:

After removing the timing belt, do not turn the crankshafts and camshafts, as the pistons can damage the valves.

If, during repair work, the timing belt is not removed for replacement, then mark the direction of movement of the belt with an arrow when the engine is running.

13. To remove the tensioner, finally unscrew and remove the lower bolt (see item 11) fasteners and remove the tensioner.

14. Inspect the crankshaft and camshaft toothed pulleys. Burrs, nicks, chipping of the working surface of the teeth are not allowed.

15. Check the tensioner 1 and intermediate 2 rollers for mechanical damage and ease of rotation. The rollers should rotate silently, without jamming, evenly. There should be no axial or radial play.

Note:

Replace defective parts if necessary.

16. Using a hex wrench, unscrew the screw securing the axle of the tension roller lever and remove the roller assembly with the lever.

17. Unscrew the screw securing the intermediate roller and remove it from the engine.

18. Reinstall the tension and intermediate rollers by tightening their bolts to a torque of 41 ± 10 Nm.

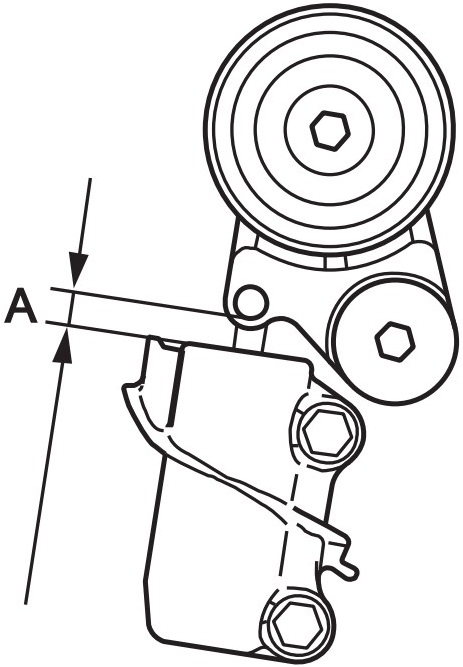

19. Visually check the automatic tensioner. Check the tensioner rod for wear and damage. Measure the free protrusion of the tensioner rod.

Note:

If protrusion A is less than 9.1 mm, replace the tensioner.

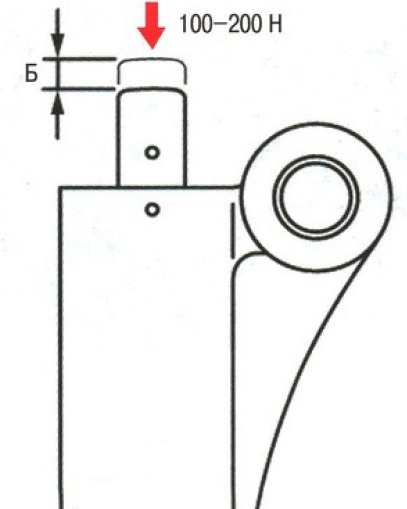

20. Place the tensioner body on a rigid support and push the rod with a force of 100-200 N. Measure the stroke B of the rod. The stroke of a working tensioner should be no more than 3 mm.

Note:

This check can be done in a vice. If stem sinks easily, replace tensioner. If the compression requires a lot of effort, the automatic tensioner is fine.

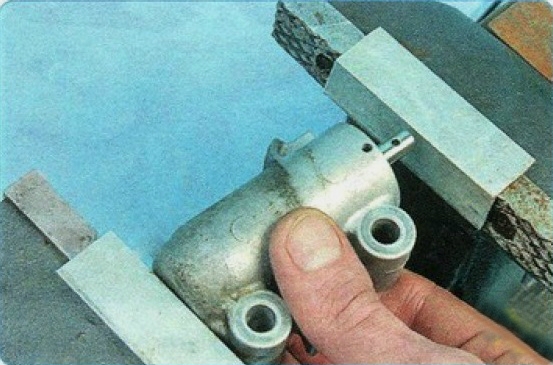

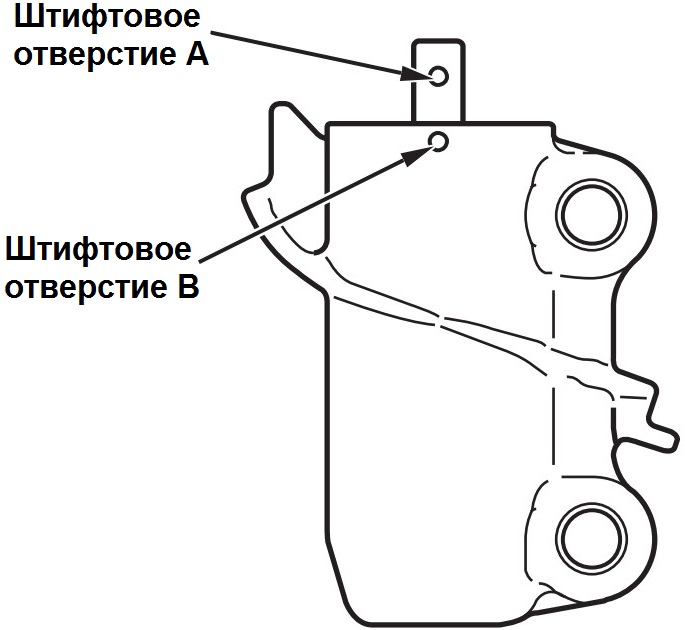

21. Slowly squeezing the tensioner in a vice with soft pads, sink the automatic tensioner rod until the holes in the rod line up with the hole in the body.

Note:

To avoid deformation and damage to the tensioner, do not squeeze it too quickly.

22. Insert a special hex key or pin (2 mm diameter) into the aligned holes of the tensioner.

23. Install the tensioner on the Outlander XL engine, tightening the bolts of its fastening to a nominal torque of 23 ± 3 Nm.

24. Check the timing marks of the Mitsubishi Outlander HL, their alignment on the crankshaft and camshaft gears.

25. Slide the new belt onto the pulleys in the following order: crankshaft pulley, water pump pulley, right camshaft toothed pulley, idler pulley, left camshaft toothed pulley, idler.

Note:

If there are arrows on the new belt, these should indicate the direction of travel of the belt when the engine is running when installed.

26. Remove the retaining bar from the tensioner hole.

27. Screw the pulley fastening bolt into the crankshaft end and turn the crankshaft by the bolt two turns clockwise. Check the alignment of the crankshaft and camshaft timing marks.

Note:

If there is a mismatch, re-install the belt.

28. Check the tension of the timing belt. If the belt is tensioned correctly, the tensioner plunger should protrude from the housing by a distance A. equal to 9.1-13.4 mm.

29. Install all removed parts in the reverse order of removal.

Note:

Nominal tightening torque of the bolts fastening the bracket of the right support to the engine block: М8 - 20 ± 5 Nm; M10 - 48 ± 11 Nm.

The nominal tightening torque of the timing cover bolts is 7 ± 1 Nm.

The article is missing:

- Tool photo

- Photos of parts and consumables

Source: carpedia.club

![1 generation [2003 - 2007]](/uploads/Mitsubishi_Outlander_I_2003_-_2008_.jpg)

![3 generation [2012 - 2014]](/uploads/3.png)

![XL [2005 - 2012]](/uploads/4d137205da66f_.jpg)