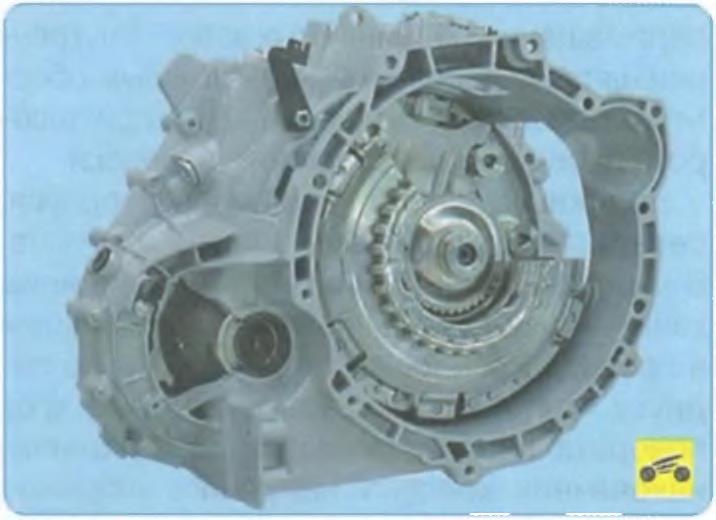

Ford Focus III vehicles are equipped with six-speed GETRAG Powershift Transmission 6DCT250 robotic gearboxes with dual dry clutch and electromechanical drive.

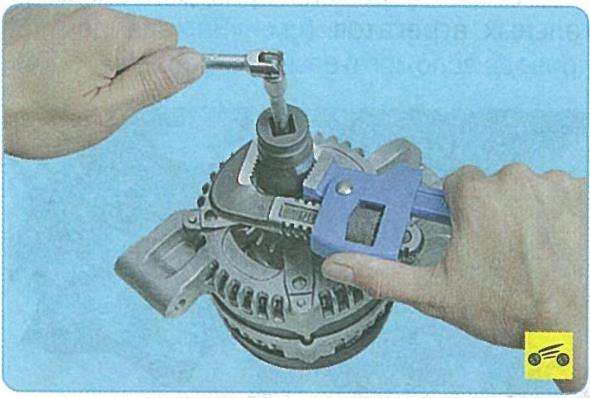

A robotic gearbox works on the same principle as a mechanical one, but it has not one, but two multi-plate clutches. Each clutch uses its own gearbox input shaft, with one shaft rotating inside the other. The inner shaft drives the 1st, 3rd, 5th and reverse gears, while the outer shaft drives the 2nd, 4th and 6th gears. The electro-hydraulic unit controls the activation of the shafts, so if one shaft is activated, the other remains in the disengaged state, and vice versa.

The reverse shaft provides a change in the direction of rotation of the output shaft and, with it, the final drive gear.

Clutches that transmit torque from the engine to the input shafts of the gearbox operate on the principle of a friction clutch: the piston compresses the clutch plates, and due to friction, the clutch locks and torque is transmitted.

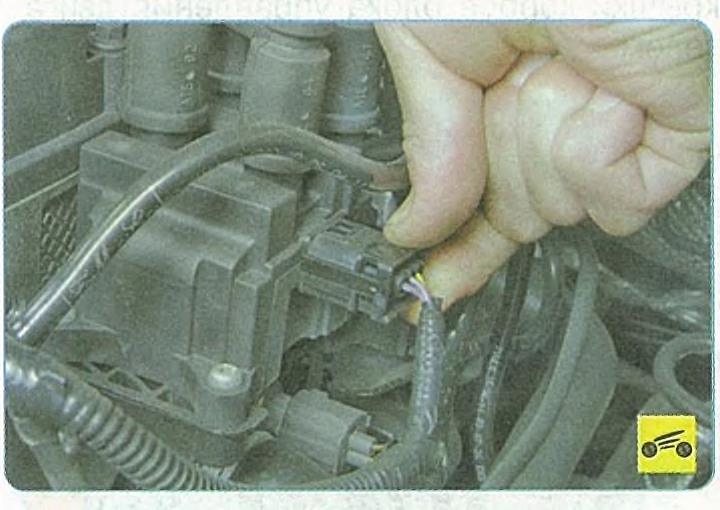

Gear shifting is carried out in automatic or manual (forced) sequential gear shifting mode without loss of torque.

The advantage of the Powershift gearbox over other robotic gearboxes is that the Powershift transmission, even in manual gearshift mode, does not allow loss of engine power, and there are no characteristic pauses when shifting gears.

Unlike a traditional automatic hydromechanical transmission, Powershift does not require components such as a torque converter, planetary gears or multi-plate friction clutches. As a result, loss of torque and engine power is eliminated.

Source: Operation, maintenance and repair manual in photographs series "Repair without problems" Third Rome

![2 generation [2004 - 2008]](/uploads/Ford_Focus_2_2004_-_2008_.jpg)

![3 generation [2011 - 2017]](/uploads/Ford_Focus_3_2011-2015_.jpg)