crankshaft position sensor

You will need: all the tools needed to remove the engine mudguards, as well as a “10” key, a tester.

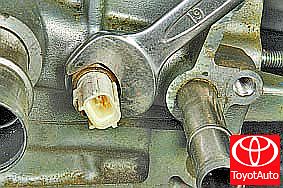

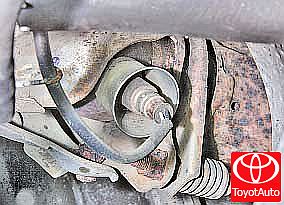

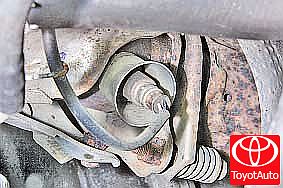

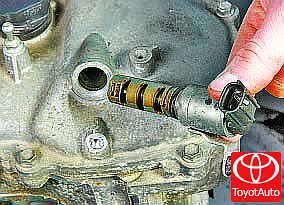

The crankshaft position sensor is located at the front of the engine block.

If a malfunction occurs in the crankshaft position sensor circuit, the engine stops working, the controller stores the malfunction code in memory and turns on the warning lamp in the instrument cluster. In this case, check the sensor and drive disc for missing teeth, runout, or other damage.

Toyota Corolla Crankshaft Position Sensor Replacement

1. Disconnect a wire from the minus plug of the storage battery.

2. Remove the right lower and side mudguards of the engine (see "Removal and installation of mudguards of the engine").

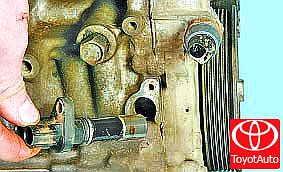

3. Disconnect the crankshaft position sensor wiring harness connector.

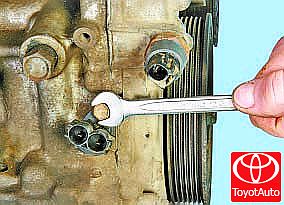

4. Turn out a bolt of fastening.

5. Remove the crankshaft position sensor.

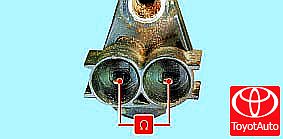

6. To check the health of the crankshaft position sensor, measure the resistance between the contacts of its block. At temperatures from +10 to +50 ° C, the resistance should be 985-1600 Ohm.

7. Install the engine crankshaft position sensor in the reverse order of removal.

Phase sensors

You will need a key "for 10".

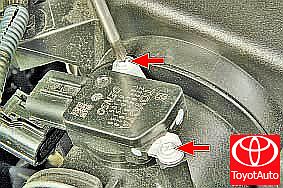

Phase sensors are installed in the left upper part of the cylinder head. In the event of a fault in the sensor circuit, the controller stores the fault code and uses a bypass engine control program (without changing the valve timing).

NOTE:

The replacement of the phase sensor on the intake shaft of the gas distribution mechanism is shown. The phase sensor on the exhaust shaft is replaced in the same way.

Toyota Corolla phase sensor replacement

1. Remove the decorative engine cover (see "Removing and installing the decorative engine cover").

2. Disconnect a wire from the minus plug of the storage battery.

3. Disconnect the wiring harness block from the phase sensor.

4. Turn out a bolt of fastening.

5. Remove the sensor from the hole in the cylinder head.

6. For check of serviceability of the gauge measure resistance between its contacts. At temperatures from +10 to +50 ° C, the resistance should be 835-1400 Ohm.

7. Install the phase sensor in the reverse order of removal.

coolant temperature sensor

You will need: key "19", tester, thermometer.

The coolant temperature sensor is screwed into the threaded hole in the cylinder head. In the event of a sensor failure, the controller stores a fault code and uses an engine management bypass program (calculates the approximate value of the coolant temperature from engine hours and air mass flow).

Toyota Corolla Coolant Temperature Sensor Replacement

1. Remove the decorative engine cover (see "Removing and installing the decorative engine cover").

2. Disconnect a wire from the minus plug of the storage battery.

3. Drain the liquid from the engine cooling system (see "Replacing the coolant").

USEFUL ADVICE:

When replacing the sensor, the coolant can not be drained: after removing the sensor, plug the hole with a finger or a plug - the loss of coolant will be minimal.

4. Disconnect the harness connector from the coolant temperature sensor by squeezing the retainer.

5. Turn out the gauge from an aperture in a head of the block of cylinders.

6. Immerse the sensor in hot water and check with a tester the change in resistance between the sensor leads as the water cools, controlling the water temperature with a thermometer. The resistance values of a good sensor are given in the table:

Data for checking the coolant temperature sensor

| Temperature, °С | Sensor resistance, kOhm |

| -twenty | 11.0-25.0 |

| 0 | 5.0-10.0 |

| +20 | 2.4-4.0 |

| +40 | 1.0-1.9 |

| +60 | 0.5-0.9 |

| +80 | 0.25-0.6 |

7. If the resistance deviates from the norm, replace the sensor.

8. Screw in the coolant temperature sensor and tighten it to 20 N?m. Install the rest of the parts in the reverse order of removal.

9. Fill in coolant.

Mass flow and intake air temperature sensor

You will need a Phillips screwdriver.

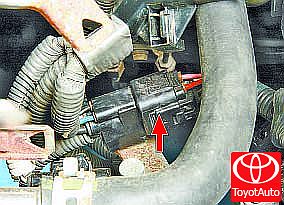

The combined mass flow and intake air temperature sensor is installed in the air hose between the air filter and the throttle assembly.

In the event of a sensor malfunction, the controller stores the malfunction code and uses an engine management bypass program (calculates the approximate mass air flow from the crankshaft speed and throttle position).

Checking the mass flow sensor and the temperature of the incoming air must be performed at a service station using a scanner connected to the diagnostic socket.

Toyota Corolla Mass Flow and Intake Air Temperature Sensor Replacement

1. Disconnect a wire from the minus plug of the storage battery.

2. Squeeze the sensor retainer.

3. Disconnect the wiring harness connector from the sensor.

4. Turn out 2 screws of fastening and remove the gauge of the mass expense and temperature of arriving air.

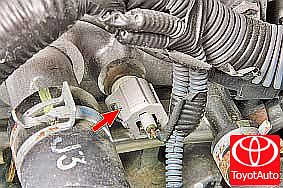

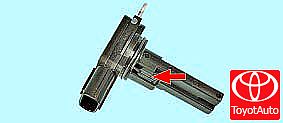

5. Inspect the platinum element of the mass air flow sensor (shown by an arrow in the photo) and make sure that it is not broken and there are foreign particles on it. If a broken platinum element is found, replace the sensor.

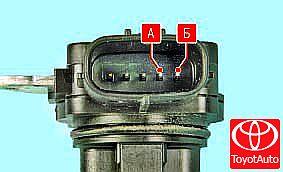

6. Check with a tester the change in resistance between terminals A and B of the sensor as the temperature changes. The resistance values of a good sensor are shown in the table.

Data for checking the mass flow sensor and the temperature of the incoming air

| Temperature, °С | Sensor resistance, kOhm |

| -twenty | 13.6-18.4 |

| +20 | 2.21-2.69 |

| +60 | 0.49-0.67 |

7. If the resistance deviates from the norm, replace the sensor.

8. Install the combined sensor in the reverse order of removal.

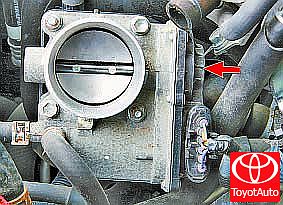

Throttle position sensor , which is based on the Hall effect, is connected to the throttle valve axis. The rotation of the damper axis causes a change in the voltage of the sensor signal, by which the controller determines the degree of throttle opening. The sensor is built into the cover of the throttle assembly, therefore, if the sensor fails, replace the throttle assembly assembly (see "Removing and installing the throttle assembly").

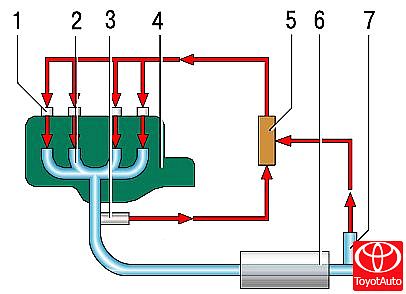

Oxygen concentration sensors

You will need: a key "for 22", a tester.

Oxygen concentration sensors are installed on the collector and exhaust pipe of the exhaust system. The sensor on the exhaust pipe is diagnostic. The sensor on the exhaust manifold is the control one.

Both sensors have a similar design, but differ in characteristics. If at least one of the oxygen concentration sensors is faulty, the toxicity of the exhaust gases can increase dramatically, and fuel consumption will increase.

Toyota Corolla Oxygen Control Sensor Replacement

1. Disconnect a wire from the minus plug of the storage battery.

2. Remove a decorative casing of the engine (see "Removal and installation of a decorative casing of the engine").

3. Squeezing the clamps, disconnect the sensor wiring harness block.

4. Unscrew the control sensor from the opening of the collector.

5. To check the serviceability of the control oxygen concentration sensor, measure the resistance between contacts "1" and "2" of its block. At a temperature of +20 ° C, the resistance should be 1.8-3.4 ohms.

6. Install the oxygen control sensor in the reverse order of removal.

Toyota Corolla Diagnostic Oxygen Sensor Replacement

1. Disconnect the wire from the "minus" terminal of the battery.

2. Remove the harness holder from the body base.

3. Squeeze the clamps and disconnect the diagnostic oxygen concentration sensor harness connector.

4. Turn out the gauge from an aperture of a reception pipe.

5. To check the health of the diagnostic oxygen concentration sensor, measure the resistance between contacts "1" and "2" of its block. At a temperature of +20 ° C, the resistance should be 11-16 ohms.

6. Install the diagnostic oxygen sensor in the reverse order of removal.

Knock sensor

You will need: all the tools to remove the engine intake pipe.

The knock sensor is mounted on a bolt screwed into the wall of the cylinder block in its upper part.

If the sensor fails, the controller memorizes the fault code and uses a bypass engine control program (with a reduced ignition timing to prevent detonation).

Replacing the knock sensor Toyota Corolla

1. Remove the decorative engine cover (see "Removing and installing the decorative engine cover").

2. Disconnect a wire from the minus plug of the storage battery.

3. Remove the engine intake pipe (see "Replacing the intake pipe seal").

4. Squeeze the sensor retainer.

5. Disconnect the wiring harness block from the knock sensor.

6. Turn out a bolt and remove the gauge of a detonation from a hairpin.

7. For check of serviceability of the gauge of a detonation measure resistance between its contacts. At a temperature of +20 ° C, the resistance should be 120-180 kOhm.

8. Install the knock sensor in the reverse order of removal.

Hydraulic Phase Change Valves

You will need a key "for 10".

The hydraulic phase change valves are mounted on the upper right side of the cylinder head cover. The valves control the oil pressure supplied to the timing actuators mounted on the front ends of the camshafts.

Toyota Corolla Phase Change Hydraulic Valve Replacement

NOTE:

The replacement of the hydraulic valve for changing the phases on the intake camshaft is shown. The hydraulic phase change valve on the exhaust camshaft is replaced in the same way.

1. Disconnect a wire from the minus plug of the storage battery.

2. Remove a decorative casing of the engine (see "Removal and installation of a decorative casing of the engine").

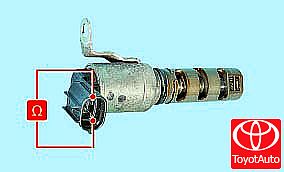

3 . Press the pad lock.

4. Disconnect the engine management harness connector from the hydraulic phase change valve.

5. Turn out a bolt of fastening of the hydraulic valve of change of phases.

6. Remove the valve from the cylinder head.

NOTES:

Pay attention to the marking of the hydraulic phase change valve in order to purchase a similar new valve.

Be sure to replace the O-rings when removing the hydraulic phase change valve.

7. For check of serviceability of the gauge of a detonation measure resistance between its contacts. At a temperature of +20 ° C, the resistance should be 6.9-7.9 ohms.

8. Install the hydraulic phase change valve in the reverse order of removal.

Source: http://toyotauto.net/corolla/proverka-i-zamena-datchikov-sistemy-upravleniya-dvigatelem.html

![E140/E150 [2006 - 2010]](/uploads/Toyota_Corolla_E140_2006_-_2010_.jpg)