Tool:

- Jack

- Support legs

- Pocket flashlight

- Mirror

- Calipers

- torque wrench

Parts and consumables:

- Dye

- Brake discs

- Bearing grease

- Wheel bolts

Signs of problems in the brake system

Dust resulting from wear on the linings and accumulating on brake components may contain asbestos that is hazardous to health. Do not blow this dust out with compressed air or inhale it! Do not use gasoline-based solvents to remove dust. Dust should be washed off with a special brake system cleaner or methyl alcohol in a drain container. After wiping brake system components with a damp cloth, keep the cloth and the contents of the drain container in a closed and labeled container. In the future, if possible, try to use asbestos-free components.

In addition to checks at regular intervals, the condition of the brake mechanisms should be carried out each time the wheels are removed or if signs of a malfunction appear in the system. To ensure driving safety, the brake check procedures described below are the most important of all vehicle maintenance procedures you perform.

1. Disc brakes may have built-in lining wear indicators that indicate that lining wear has reached a critical value. In this case, the pads should be changed immediately, otherwise the brake discs will be damaged and they will require costly repairs.

2. Any of the following symptoms may indicate a potential defect in the brake system.

Signs of defects in the brake system:

- when depressing the brake pedal, the car “takes away” in one direction;

- brakes make screeching or screeching noises when braking;

- the brake pedal has excessive travel;

- the brake pedal pulsates (this is normal only when the ABS system is working);

- there are brake fluid leaks (usually on the inside of the tire or wheel).

3. If at least one of these signs is found, immediately inspect the elements of the brake system.

Brake lines and hoses

Notes:

The brake system mainly uses steel brake pipes, with the exception of flexible reinforced hoses at the front wheels and as connections at the rear axle. Regular inspection of all these lines is very important.

1 . Park the vehicle on level ground and turn off the engine. Remove wheel covers.

Loosen but do not remove all four wheel bolts.

2. Jack up the vehicle and place it securely on jack stands.

3. Remove the wheels.

4. Check all brake lines and hoses for cracks and chafing in their outer coating, leaks, swelling and deformation. Check the brake hoses at the front and rear of the vehicle for signs of softening, cracking, deformation, or wear due to rubbing against other components. Check all fittings for signs of leaks and make sure all bolts and brake hose clamps are secure.

5. Bend the brake hose back and forth with your hands to check for damage. Hoses should not be twisted. Pay attention to the direction of the colored line marked on the hose!

6. Turn a steering wheel to the right and to the left against the stop. The hoses must not touch the structural elements of the vehicle. If fluid leaks or damage is found, they must be repaired immediately.

Checking the thickness of the brake pads

1. The thickness of the outer brake pads can be checked through the hole in the wheel rim with a flashlight. The inner shoe can be checked with a flashlight and a mirror. If you need to more accurately estimate the thickness of the pad, you should remove the wheel and measure the pad with a caliper.

Note:

Experience shows that wheel brake pad wear on the front passenger side is greater than on the driver's side. Therefore, to check the thickness of the brake pad, it is recommended to remove the wheel from the front passenger side.

2. Mark with paint the position of the front wheel in relation to the hub. This will allow you to set the balanced wheel in its working position. Loosen the wheel bolts. In this case, the car must be on the ground.

3. Raise the front of the vehicle and place on stands. Remove the front wheel.

4. Check the thickness of the inner and outer pads through the hole in the caliper.

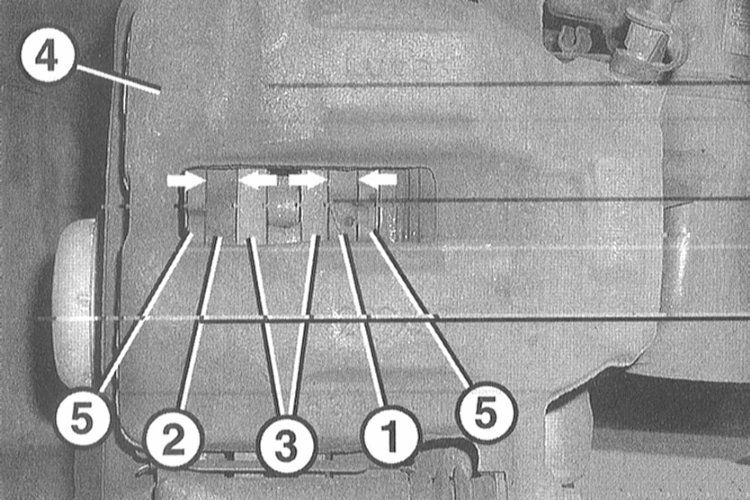

Brake system components:

1 - inner block;

2 - external block;

3 - brake disc;

4 - hole in the caliper;

5 - pad pad.

5. The brake pad thickness wear limit is reached if the pad lining is 2.0 mm thick. In this case, the brake pad must be replaced.

Note:

In practice, 1 mm of brake pad wear corresponds to at least 1,000 km of a car's run. This rule corresponds to adverse operating conditions of the vehicle. Under normal conditions, pad wear is significantly less. With a pad thickness of 10.0 mm (with base plate), the pad can still be used for at least 3000 km.

6. Check up a possibility of leak of a brake liquid in support. In the presence of leaks, urgently repair the caliper (service station work).

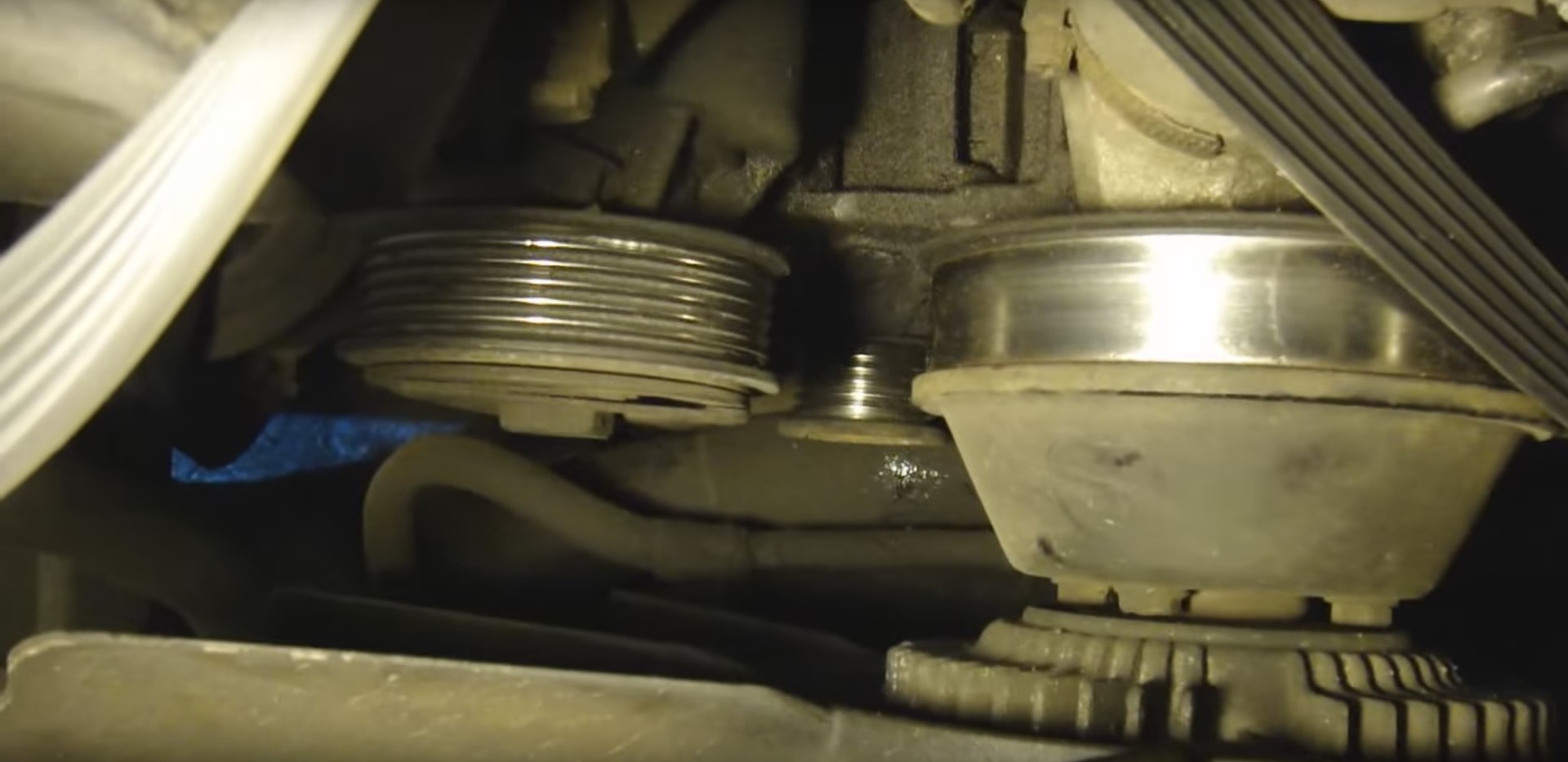

7. Visually inspect the brake discs for grooves, corrosion, and cracks. Ventilated discs with hairline cracks up to 25 mm long, which may be caused by increased stress, do not need to be replaced. In case of cracks and grooves with a depth of more than 0.5 mm, the brake discs must be replaced.

8. Check the thickness of the brake discs.

9. Reinstall the front wheels so that the marks made during removal match. Pre-lubricate with a thin layer of bearing grease centering the belt of the wheel disc on the hub. Do not grease wheel bolts. Replace rusty bolts. Wrap bolts. Lower the vehicle onto the wheels and tighten the bolts crosswise to 110 Nm.

The article is missing:

- Tool photo

- Photo of parts and consumables

- High-quality repair photos

Source: http://auto-knigi.com/model/mb_c/3_8/

![W203/S203/CL203 [2000 - 2004]](/uploads/mercedes-c-klass-w203.jpg)