Consider the principle of operation of the second generation VVT-i system, which is now used on most Toyota engines.

The VVT-i system (Variable Valve Timing intelligent - variable valve timing) allows you to smoothly change the valve timing in accordance with engine operating conditions. This is achieved by turning the intake camshaft relative to the exhaust shaft in the range of 40-60 ° (by the angle of rotation of the crankshaft). As a result, the moment when the intake valves start opening and the value of the "overlapping" time (that is, the time when the exhaust valve is not yet closed, and the intake valve is already open) change.

1. Design

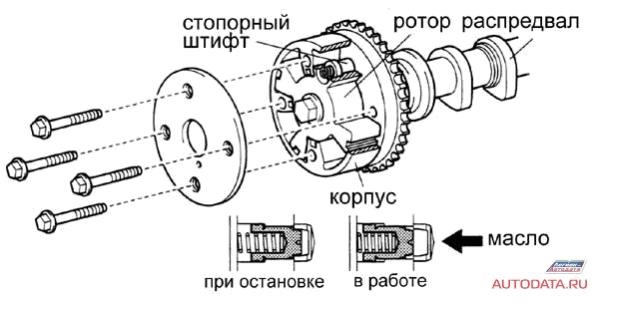

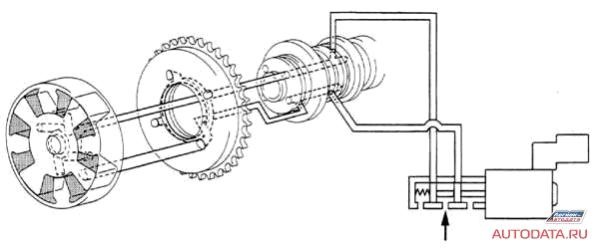

The VVT-i actuator is located in the camshaft pulley - the drive housing is connected to an asterisk or toothed pulley, the rotor is connected to the camshaft.

Oil is supplied from one side or the other of each of the petals of the rotor, causing it and the shaft itself to turn. If the engine is off, then the maximum delay angle is set (that is, the angle corresponding to the latest opening and closing of the intake valves). So that immediately after starting, when the pressure in the oil line is still not enough to effectively control the VVT-i, there are no shocks in the mechanism, the rotor is connected to the housing with a locking pin (then the pin is pressed out by oil pressure).

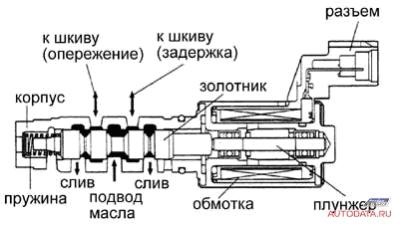

VVT-i is controlled by the VVT-i valve (OCV - Oil Control Valve).

At the signal of the control unit, the electromagnet moves the main spool through the plunger, bypassing the oil in one direction or another. When the engine is off, the spool is moved by a spring so that the maximum delay angle is set.

2

2

2. Operation

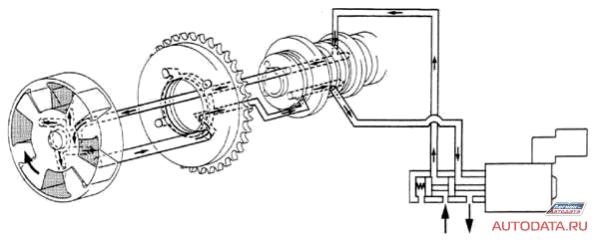

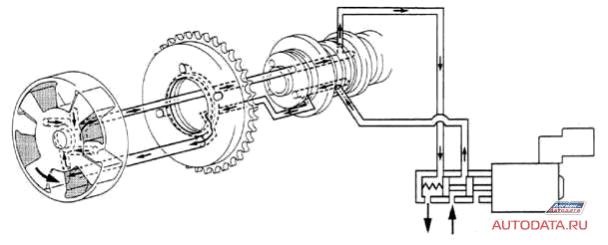

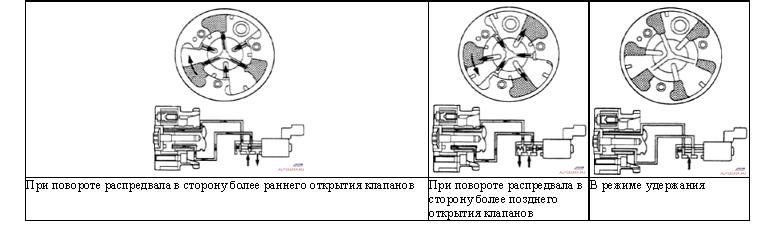

To turn the camshaft, oil under pressure is directed to one of the sides of the rotor petals with the help of a spool, while the cavity on the other side of the petal opens to drain. After the control unit determines that the camshaft has taken the desired position, both channels to the pulley overlap and it is held in a fixed position.

When turning the camshaft in the direction of an earlier opening of the valves

When turning the camshaft in the direction of a later opening of the valves

On hold

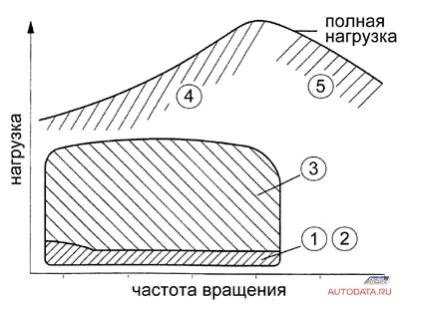

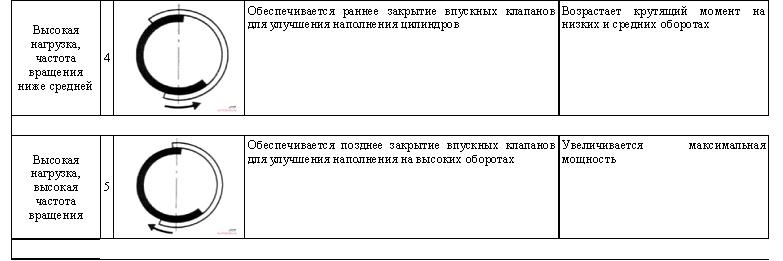

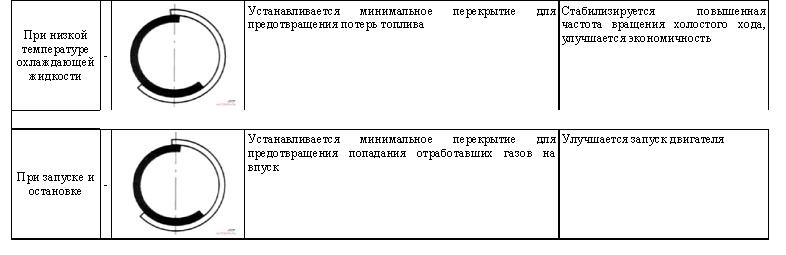

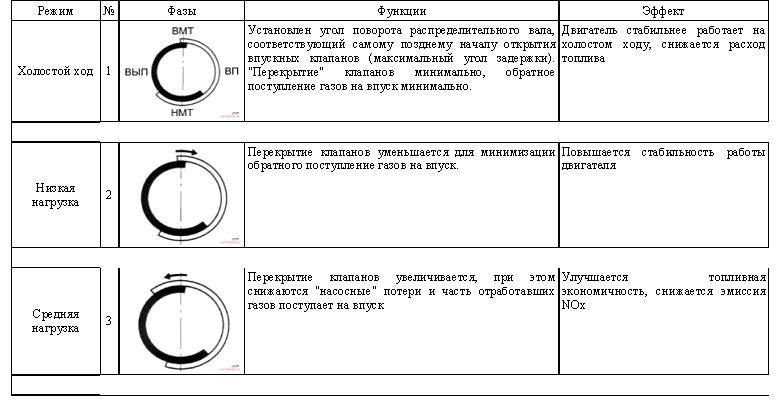

The functioning of the VVT-i system is determined by the operating conditions of the engine in various modes.

9

9

3. Variations

The above 4-blade rotor allows you to change the phases within 40 ° (as, for example, on engines of the ZZ and AZ series), but if you want to increase the angle of rotation (up to 60 ° for SZ), a 3-blade rotor is used or the working cavities are expanded.

The principle of operation and modes of operation of these mechanisms are absolutely similar, except that due to the extended range of adjustment, it becomes possible to completely eliminate valve overlap at idle, at low temperatures or at startup.

Source: https://www.drive2.ru/l/6936759/

Source: https://www.drive2.ru/l/6936759/

![E140/E150 [2006 - 2010]](/uploads/Toyota_Corolla_E140_2006_-_2010_.jpg)