The design of the G4FA (1.4 l) and G4FC (1.6 l) engines is almost the same. The differences are related to the dimensions of the parts of the crank mechanism, since the piston strokes of the engines are different. The engine is gasoline, four-stroke, four-cylinder, in-line, sixteen-valve, with two camshafts. Located transversely in the engine compartment. The order of operation of the cylinders: 1-3-4-2, counting - from the auxiliary drive pulley.

The power system is a phased distributed fuel injection (Euro-4 toxicity standards).

The engine with gearbox and clutch form a power unit - a single unit, fixed in the engine compartment on three elastic, rubber-metal bearings.

On the right are: a support that is attached to a bracket attached to the right to the head and cylinder block, and the left and rear supports are attached to the brackets on the gearbox housing. On the right side of the engine (in the direction of vehicle movement) are located: a gas distribution mechanism drive (by a chain); drive of the coolant pump, generator, power steering pump and air conditioning compressor (poly V-belt).

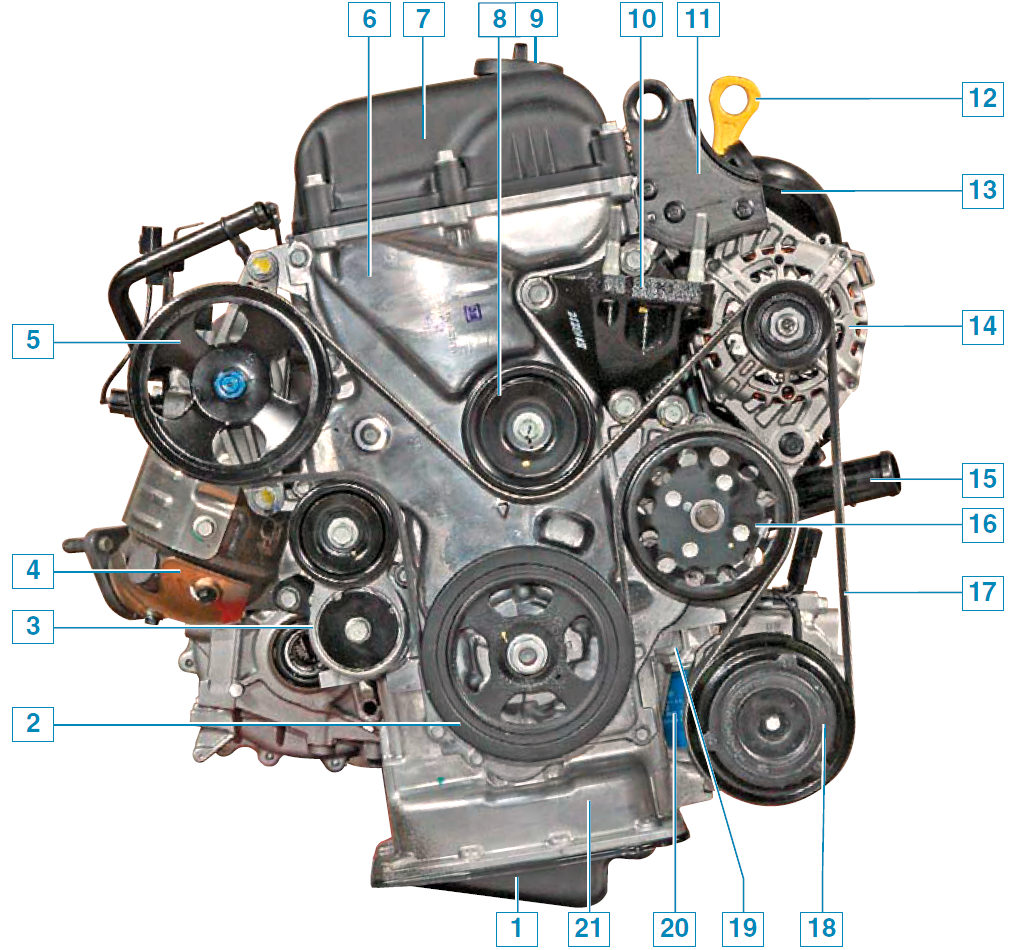

Elements of the engine (view from the right in the direction of the car):

1 - cover of the oil pan;

2 – a pulley of a drive of auxiliary units;

3 - mechanism for tensioning the drive belt of auxiliary units;

4 – collector;

5 – a pulley of the pump of the hydraulic booster of a steering;

6 – a cover of a drive of the gas-distributing mechanism;

7 – a cover of a head of the block of cylinders;

8 - guide roller of the auxiliary drive belt;

9 - oil filler cap;

10 – an arm of the right support of the power unit;

11 - eye;

12 - oil level indicator;

13 - inlet pipeline;

14 - generator;

15 - thermostat cover;

16 – a pulley of the pump of a cooling liquid;

17 – a belt of a drive of auxiliary units;

18 - electromagnetic clutch of the air conditioner compressor;

19 - cylinder block;

20 - oil filter;

21 - oil pan.

On the left are: the outlet pipe of the cooling system; coolant temperature sensor; canister purge valve.

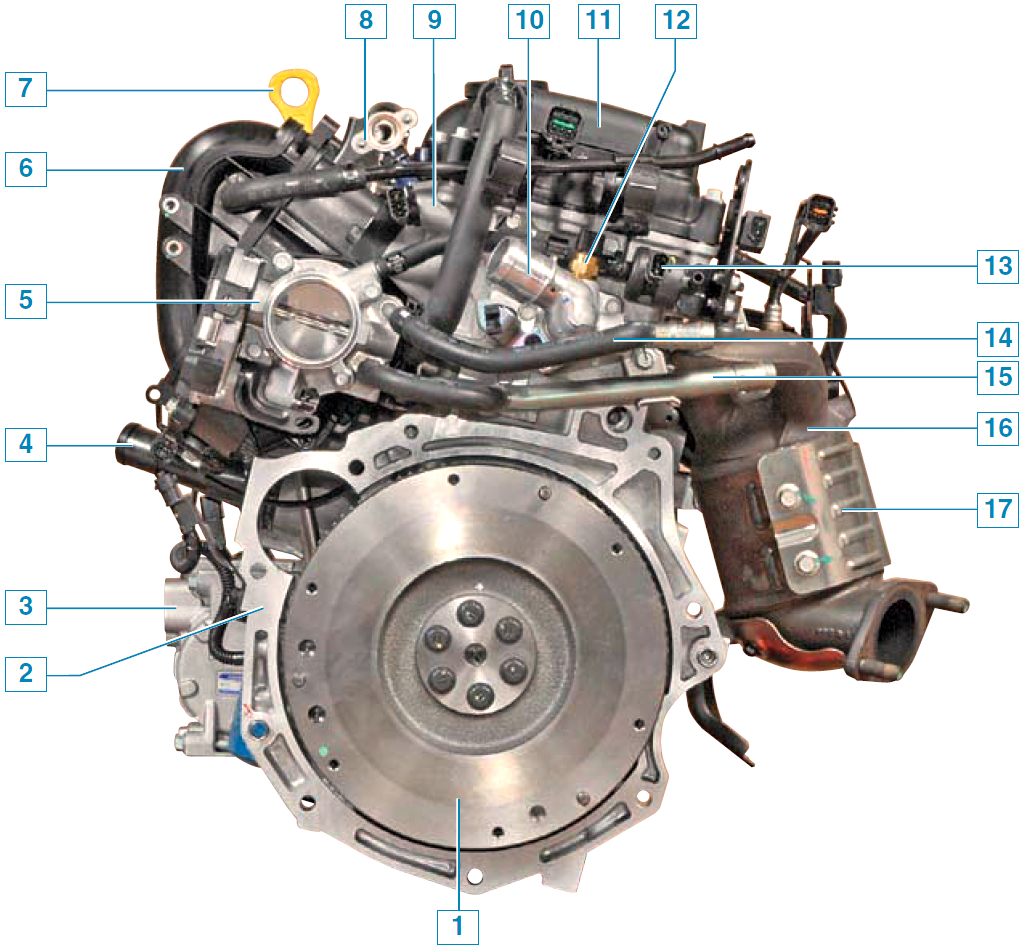

Elements of the engine (view from the left in the direction of the car):

1 - flywheel;

2 - block of cylinders;

3 - air conditioner compressor;

4 - thermostat cover;

5 - throttle assembly;

6 - inlet pipeline;

7 - oil level indicator; coolant pump inlet pipe;

8 - fuel rail;

9 – a head of the block of cylinders;

10 - outlet branch pipe of the cooling system;

11 – a cover of a head of the block of cylinders;

12 - coolant temperature sensor;

13 – adsorber purge valve;

14 - hose for supplying coolant to the heating unit of the throttle assembly;

15 - tube for supplying coolant to the pump;

16 - collector;

17 - heat shield.

Front: intake manifold with throttle assembly, fuel rail with injectors, oil filter, oil gauge, alternator, starter motor, A/C compressor, thermostat, crankshaft position sensor, camshaft position sensor, knock sensor, low oil pressure warning sensor, system valve changes in valve timing.

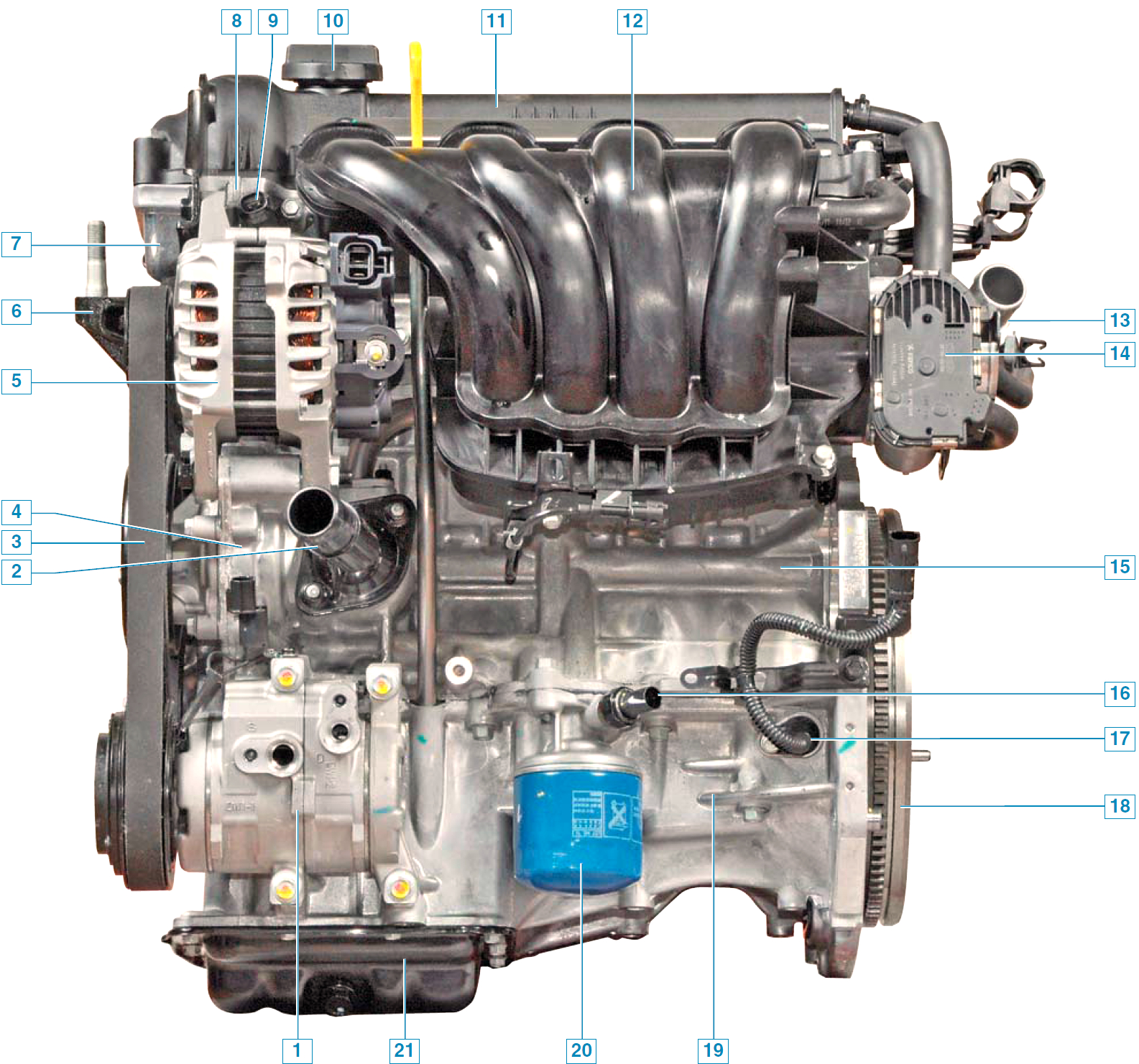

Elements of the engine (front view in the direction of the vehicle):

1 - air conditioning compressor;

2 - thermostat cover;

3 – a belt of a drive of auxiliary units;

4 - coolant pump;

5 - generator;

6 – an arm of the right support of the power unit;

7 – a cover of a drive of the gas-distributing mechanism;

8 – a head of the block of cylinders;

9 - valve of the system for changing the valve timing;

10 - oil filler cap;

11 – a cover of a head of the block of cylinders;

12 - inlet pipeline;

13 - outlet pipe of the cooling system;

14 - throttle assembly control unit;

15 - cylinder block;

16 - low oil pressure indicator sensor;

17 - crankshaft position sensor;

18 - flywheel;

19 - oil pan;

20 - oil filter;

21 - cover of the oil pan.

Rear: collector, oxygen concentration control sensor, power steering pump. Above: coils and spark plugs. The cylinder block is cast from an aluminum alloy using the Open-Deck method with a single cylinder casting free-standing in the upper part of the block. In the lower part of the cylinder block there are crankshaft bearings - five beds of main shaft bearings with removable covers, which are attached to the block with special bolts. The holes in the cylinder block for the main bearings (liners) of the crankshaft are machined complete with covers, so the covers are not interchangeable. On the end surfaces of the middle (third) support there are slots for two thrust half rings that prevent axial movement of the crankshaft.

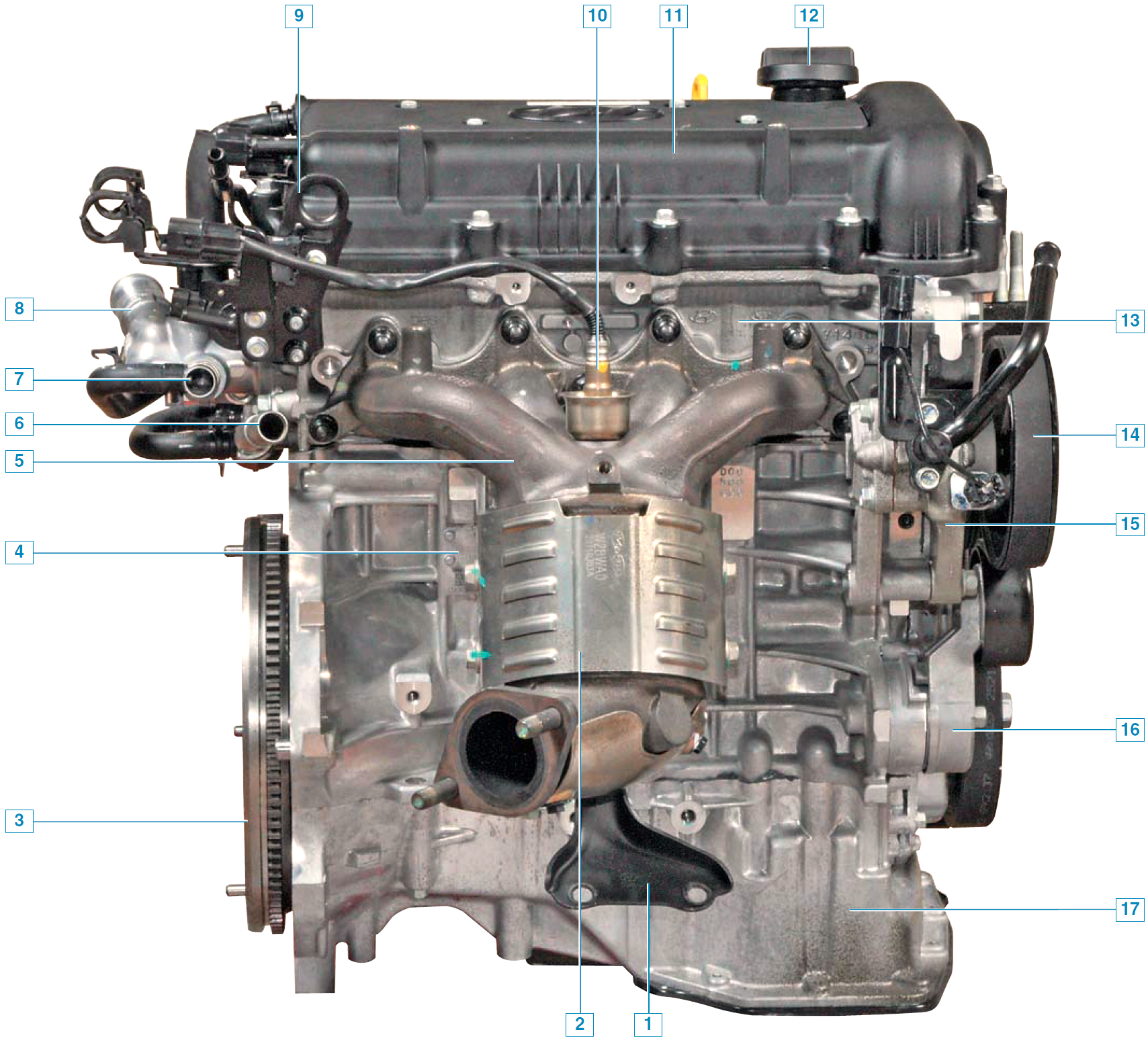

Elements of the engine (rear view in the direction of the car):

1 – collector bracket;

2 - heat shield;

3 - flywheel;

4 - block of cylinders;

5 – collector;

6 - tube for supplying coolant to the pump;

7 - tube for supplying coolant to the heater radiator;

8 - outlet branch pipe of the cooling system;

9 - eye;

10 – control oxygen concentration sensor;

11 – a cover of a head of the block of cylinders;

12 - oil filler cap;

13 – a head of the block of cylinders;

14 – a belt of a drive of auxiliary units;

15 - power steering pump;

16 - mechanism for tensioning the drive belt of auxiliary units;

17 - oil pan.

Crankshaft- made of high-strength cast iron, with five main and four connecting rod journals. The shaft is equipped with four counterweights, made on the continuation of the two extreme and two middle "cheeks". Counterweights are designed to balance the forces and moments of inertia arising from the movement of the crank mechanism during engine operation. Inserts of main and connecting rod bearings of the crankshaft are steel, thin-walled, with an anti-friction coating. The main and connecting rod journals of the crankshaft connect channels drilled in the body of the shaft, which serve to supply oil from the main to the connecting rod bearings of the shaft. At the front end (toe) of the crankshaft are installed: a timing gear (timing) sprocket, an oil pump gear and an auxiliary drive pulley, which is also a damper for torsional vibrations of the shaft. A flywheel is attached to the crankshaft flange with six bolts, which makes it easier to start the engine, ensures that its pistons are brought out of dead spots and more uniform rotation of the crankshaft when the engine is idling. The flywheel is cast iron and has a pressed steel ring gear for starting the engine with a starter.

Crankshaft.

Connecting rods - forged steel, I-section. With their lower split heads, the connecting rods are connected through liners to the connecting rod journals of the crankshaft, and the upper heads are connected through piston pins to the pistons.

The connecting rod caps are attached to the connecting rod body with special bolts.

The pistons are made of aluminum alloy. Three grooves for piston rings are machined in the upper part of the piston. The two upper piston rings are compression rings, and the lower one is oil scraper.

Connecting rod.

Compression rings prevent the breakthrough of gases from the cylinder into the crankcase and contribute to the removal of heat from the piston to the cylinder. The oil scraper ring removes excess oil from the cylinder walls as the piston moves. Piston pins steel, tubular section. In the holes of the pistons, the fingers are installed with a gap, and in the upper heads of the connecting rods - with an interference fit (pressed).

compression rings.

The cylinder head , cast from an aluminum alloy, is common to all four cylinders. It is centered on the block with two bushings and fastened with ten bolts.

A non-shrink metal-reinforced gasket is installed between the block and the cylinder head.

On opposite sides of the cylinder head are the intake and exhaust ports. Spark plugs are installed in the center of each combustion chamber.

Two camshafts are installed at the top of the cylinder head. One shaft drives the intake valves of the gas distribution mechanism, and the other drives the exhaust valves. A design feature of the camshaft is that the cams are pressed onto the tubular shaft. The valves are actuated by camshaft lobes through cylindrical tappets.

Eight cams are made on each shaft - an adjacent pair of cams simultaneously controls two valves (inlet or outlet) of each cylinder. The supports (bearings) of the camshafts (five supports for each shaft) are made detachable. The holes in the supports are machined complete with covers. The front cover (on the timing drive side) of the bearings is common to both camshafts. The camshaft drive is a chain from the crankshaft sprocket. The hydromechanical tensioner automatically provides the required chain tension during operation. The valves in the cylinder head are arranged in two rows, in a V-shape, with two intake and two exhaust valves for each cylinder. Steel valves, exhaust valves with heat-resistant steel plate and welded chamfer.

The intake valve has a larger diameter than the exhaust valve. Seats and valve guides are pressed into the cylinder head. On top of the valve guide bushings, valve stem seals made of oil-resistant rubber are put on. The valve closes under the action of a spring. Its lower end rests on a washer, and its upper end rests on a plate held by two crackers. The crackers folded together have the shape of a truncated cone, and on their inner surface there are beads that enter the grooves on the valve stem.

A design feature of the engine is the presence of a variable valve timing system (CVVT), i.e. changes in the moment of opening and closing the valves. The system ensures the installation of optimal valve timing for each moment of engine operation, in order to increase its power and dynamic characteristics, by changing the position of the intake camshaft. The system is controlled by an electronic engine control unit (ECU).

Elements of the cylinder head assembly (block head cover removed):

1 – a camshaft of inlet valves;

2 - exhaust camshaft.

The main elements of the CVVT system are the control solenoid valve, the camshaft position actuator and the camshaft position sensor.

The solenoid valve for the phase change system is installed in the seat of the cylinder head.

The timing chain drives the system's actuator, which transmits rotation to the camshaft using hydromechanical coupling.

The actuator of the phase change system is installed on the toe of the intake camshaft and is aligned with the shaft drive sprocket.

From the oil line, engine oil under pressure is supplied through the channels to the cylinder head socket, in which the valve is installed, and then, through the channels in the head and camshaft, to the system actuator.

At the ECU commands, the spool device of the solenoid valve controls the supply of oil under pressure to the working cavity of the actuator or the draining of oil from it. Due to the change in oil pressure and hydromechanical action, the individual elements of the actuator are mutually moved, and the camshaft rotates to the required angle, changing the valve timing. The solenoid valve spool and system actuator components are very sensitive to engine oil contamination. When the phase change system fails, the inlet valves open and close in the maximum delay mode.

Solenoid valve of the phase change system.

Engine lubrication - combined. Under pressure, oil is supplied to the main and connecting rod bearings of the crankshaft, pairs of "support - camshaft journal", chain tensioner and the actuator of the variable valve timing system.

The pressure in the system is created by an oil pump with internal gears and a pressure reducing valve. The oil pump housing is attached to the timing cover from the inside. The drive gear of the pump is driven from the toe of the crankshaft. The pump takes oil from the oil pan through the oil receiver and delivers it through the oil filter to the main line of the cylinder block, from which the oil channels depart to the crankshaft main bearings. Oil is supplied to the connecting rod bearings of the crankshaft through channels made in the body of the shaft. A vertical channel departs from the main line for supplying oil to the camshaft bearings and channels in the cylinder head, the variable valve timing system.

Excess oil is drained from the cylinder head into the oil pan through special drainage channels.

The oil filter is full-flow, non-separable, equipped with bypass and anti-drain valves. Oil is sprayed onto pistons, cylinder walls and camshaft lobes. Engine crankcase ventilation system - forced, closed type. Depending on the engine operating modes (partial or full load, idling), crankcase gases from under the cylinder head cover enter the intake tract through the hoses of two circuits. In this case, the gases are cleaned of oil particles, passing through the oil separator located in the cylinder head cover.

Oil filter.

crankcase ventilation valve.

When the engine is idling and at low load modes, when the vacuum in the intake manifold is high, crankcase gases are taken from the engine through the ventilation system valve located in the cylinder head cover, and are fed through the hose to the intake pipeline, into the space behind the throttle valve.

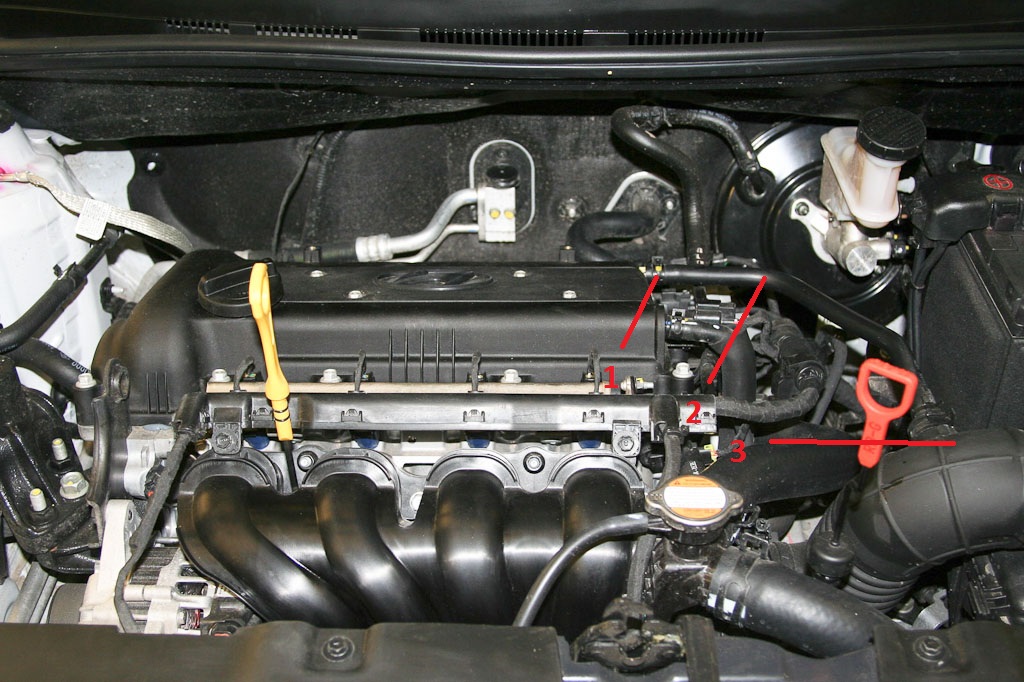

Place of installation of the valve of the ventilation system.

Depending on the vacuum in the intake manifold, the valve regulates the flow of crankcase gases entering the engine cylinders.

At full load modes, when the vacuum in the intake manifold decreases, crankcase gases from under the cylinder head cover enter the engine cylinders through the cover fitting 1 connected by hose 2 to hose 3 for supplying air to the throttle assembly.

The article is missing:

- High-quality repair photos

Source: http://carpedia.club/

![1 generation [2010 - 2014]](/uploads/Hyundai_Solaris_2010_-_2014_.jpg)