Инструменты (для двигателей 4B12/4B11):

- Гаечный ключ рожковый на 10 мм

- Ключ трещоточный

- Удлинитель

- Головка на 10 мм

- Свечной ключ (или высокая головка на 16 мм)

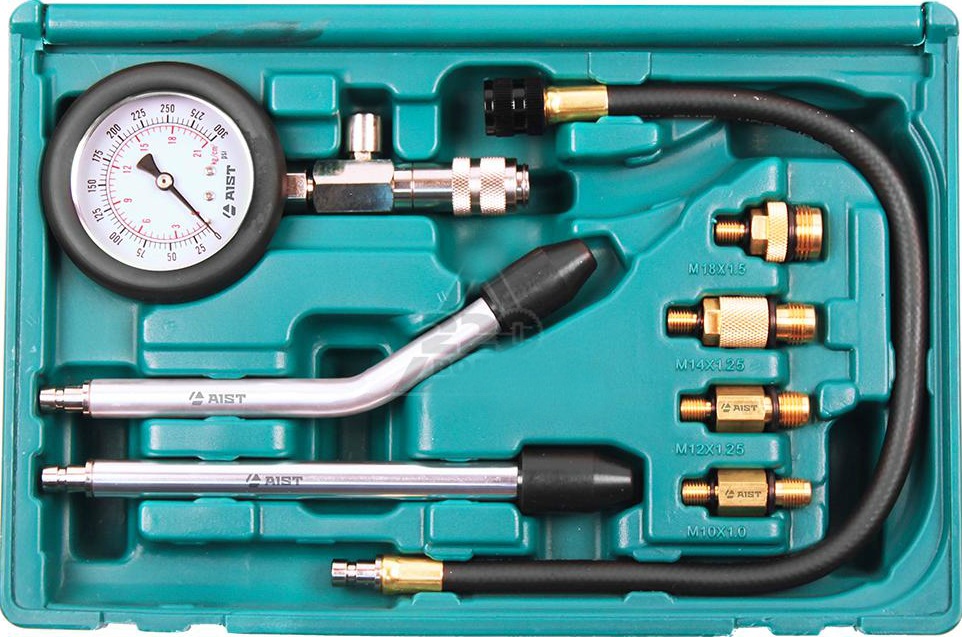

- Компрессометр

- Шприц (при необходимости)

- Компрессор (при необходимости)

Инструменты (для двигателя 6B31):

- Гаечный ключ рожковый на 8 мм

- Гаечный ключ рожковый на 10 мм

- Ключ трещоточный

- Удлинитель

- Головка на 10 мм

- Головка на 12 мм

- Отвертка плоская средняя

- Отвертка крестовая средняя

- Круглогубцы изогнутые

- Плоскогубцы

- Нож (или скребок)

- Динамометрический ключ

- Свечной ключ (или высокая головка на 16 мм)

- Компрессометр

- Шприц (при необходимости)

- Компрессор (при необходимости)

Детали и расходники:

- Уплотнительная прокладка верхней части впускного коллектора 1540A193 (для двигателя 6B31)

- Моторное масло (при необходимости)

- Шланг (при необходимости)

- Очиститель (или растворитель, для двигателя 6В31, при необходимости)

- Ветошь

Примечания:

Диагностика двигателей Мицубиси Аутлендер ХЛ без разборки осуществляется с помощью измерения компрессии. По ее среднему значению и по разнице значений в отдельных цилиндрах можно с достаточной точностью определить степень общего износа деталей цилиндро-поршневой группы двигателя, а также выяснить неисправности этой группы и деталей клапанного механизма.

Замер компрессии в двигателе осуществляется специальным прибором – компрессометром. Они бывают немного разного исполнения. С резьбовым штуцером, который вкручивают в гнездо свечи зажигания. И компрессометры с резиновым наконечником, которые просто необходимо крепко вжимать в свечное отверстие.

Важными условиями правильности показаний при проверке компрессии являются исправность стартера и его электрических цепей, а также полная заряженность аккумуляторной батареи.

1. Пустите двигатель и прогрейте его до рабочей температуры.

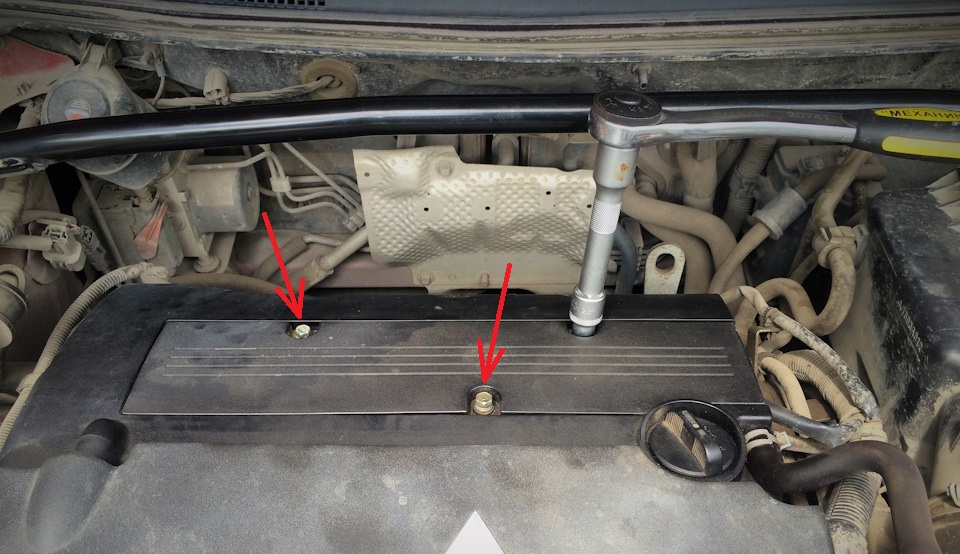

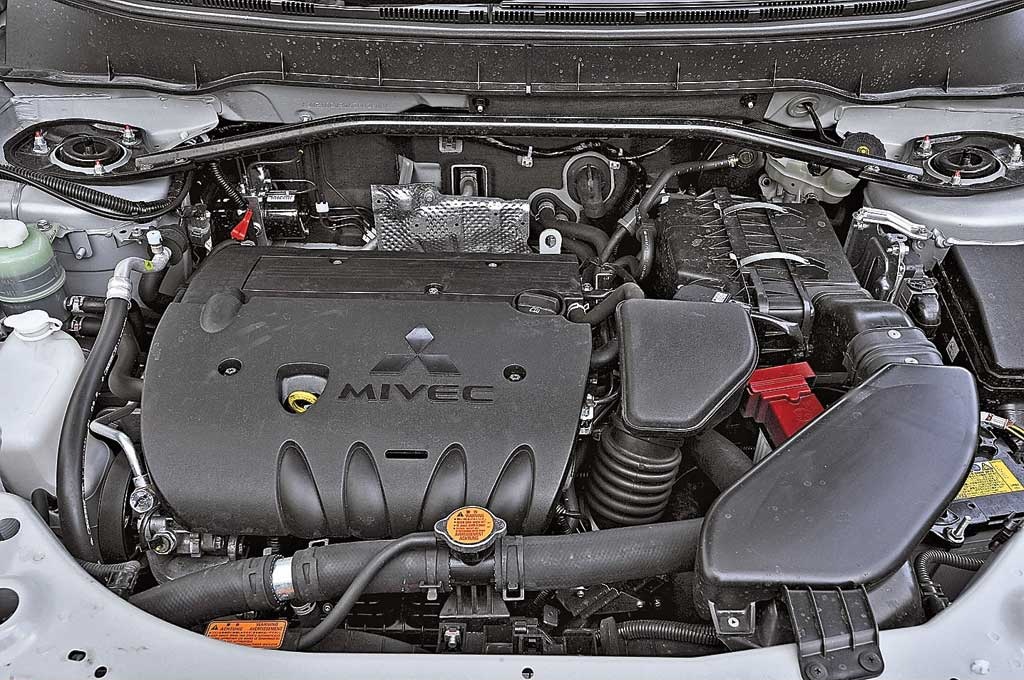

2.1. (двигатель 4B11/4B12) Откройте капот и отверните головкой на 10 мм три болта крепления пластины крышки головки блока цилиндров.

2.2. (двигатель 6В31) Снимите декоративный кожух двигателя и впускной коллектор.

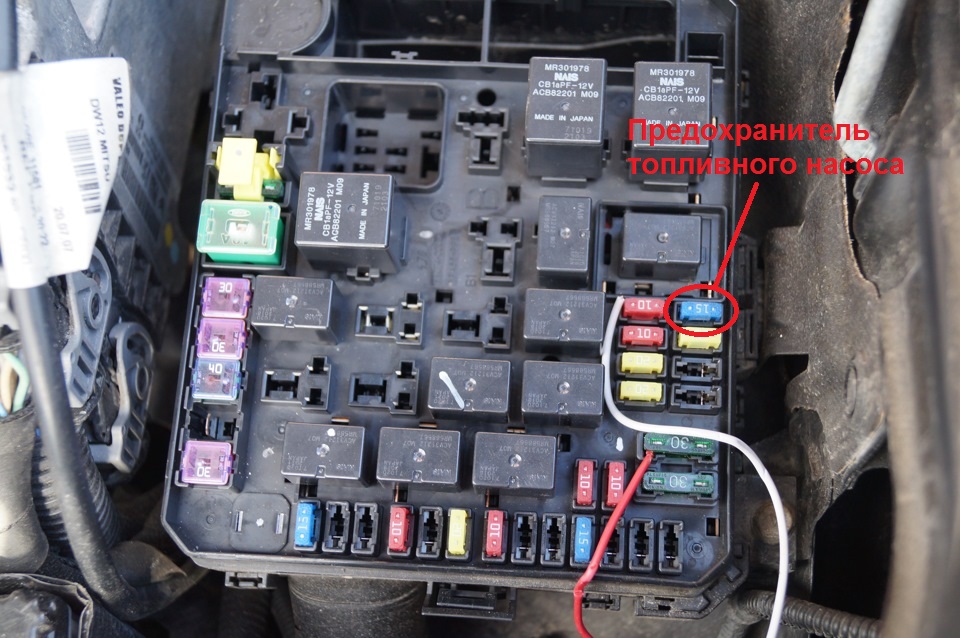

3. Снизьте давление в системе питания двигателя, как описано в этой статье.

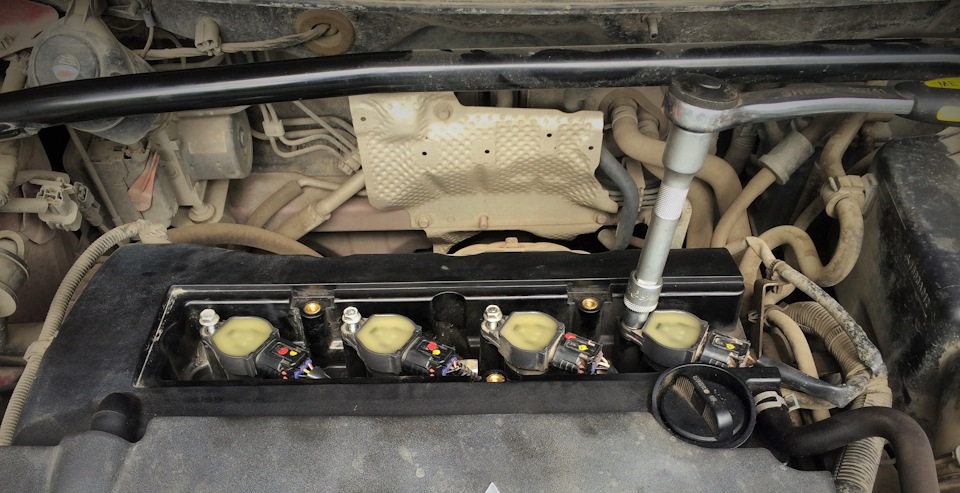

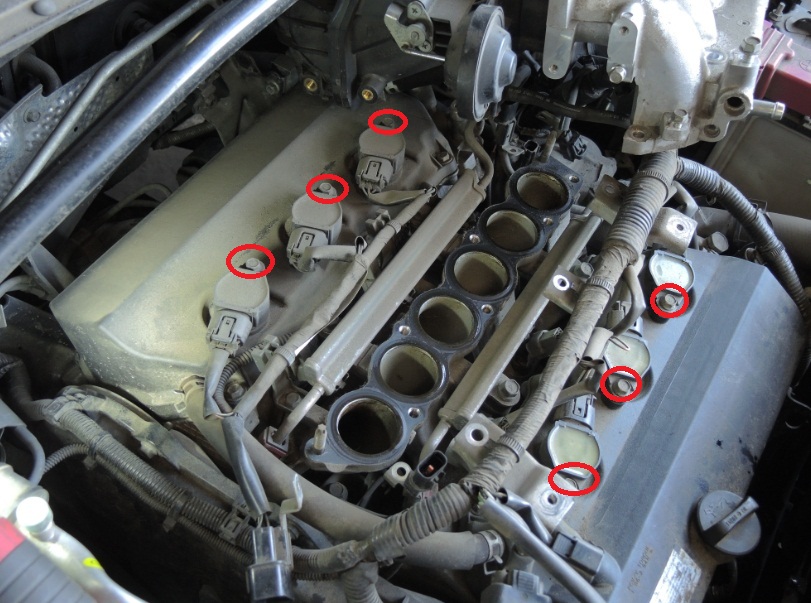

4. Отсоедините колодки проводов от катушек зажигания.

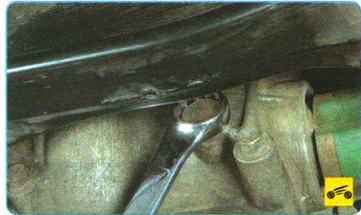

5. Головкой на 10 мм отверните болты крепления катушек зажигания (первых два фото – двигатель 4B12; третье фото – двигатель 6B31).

6. Выньте катушки зажигания из свечных колодцев, потянув их вверх.

Примечание:

Будьте в обращении с катушками крайне осторожными. Даже малейший удар по ним может привести к их выходу из строя.

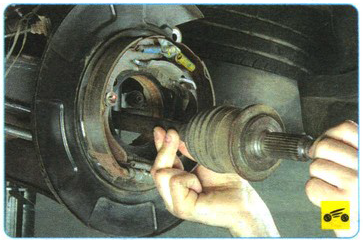

7. Выверните свечу зажигания и извлеките ее из свечного колодца.

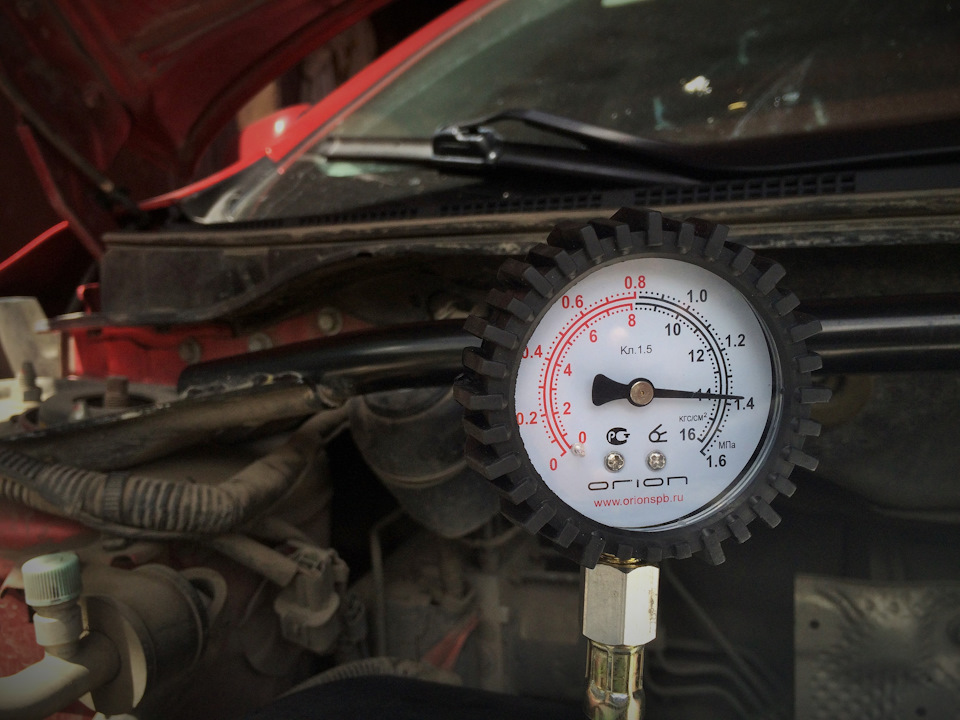

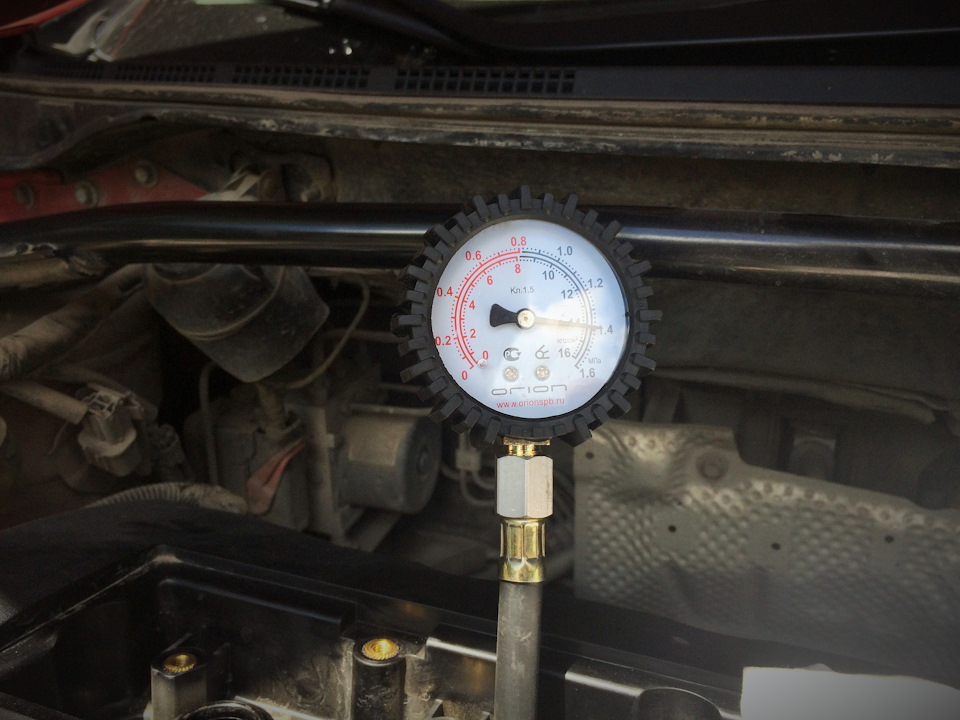

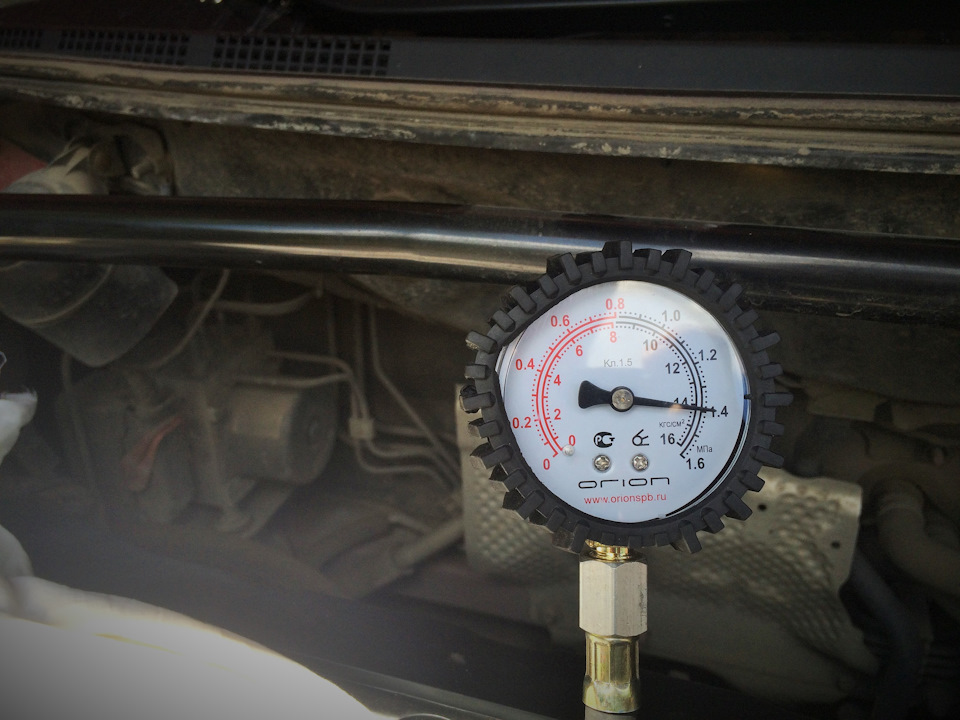

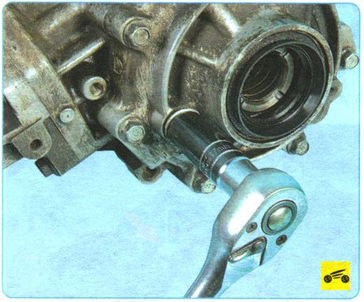

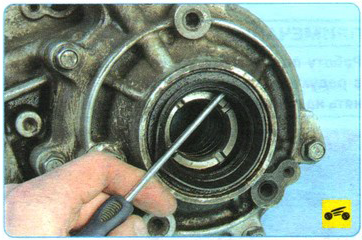

8. Вверните компрессометр в свечное отверстие проверяемого цилиндра.

9. Нажмите на педаль акселератора до упора, чтобы при проворачивании коленчатого вала стартером дроссельная заслонка полностью открылась в режиме продувки цилиндров двигателя.

10. Включите стартер и проворачивайте им коленчатый вал двигателя до тех пор, пока давление в цилиндре не перестанет увеличиваться. Это соответствует примерно четырем тактам сжатия.

Примечание:

Для получения правильных показаний компрессометра коленчатый вал должен вращаться с частотой 180-200/мин. или выше, но не более 350/мин.

11. Запишите показания компрессометра и установите его стрелку на ноль, нажав на клапан выпуска воздуха.

Примечание:

У компрессометров иной конструкции показания могут сбрасываться другими способами (в соответствии с инструкцией к прибору).

12. Повторите операции 8-11 для остальных цилиндров. Давление должно быть не ниже 1,0 МПа и не должно отличаться в разных цилиндрах более чем на 0,1 МПа.

Примечание:

Низкая компрессия в одном цилиндре может возникнуть в результате неплотной посадки клапанов в седлах, повреждения прокладки головки блока цилиндров, поломки или пригорания поршневых колец. Пониженная компрессия во всех цилиндрах указывает на износ поршневых колец.

13. Для выяснения причин недостаточной компрессии залейте шприцом со шлангом в цилиндр с пониженной компрессией около 20 мл чистого моторного масла и вновь измерьте компрессию.

Примечание:

Если показания компрессометра повысились, наиболее вероятна неисправность поршневых колец. Если компрессия осталась неизменной, значит, тарелки клапанов неплотно прилегают к их седлам или повреждена прокладка головки блока цилиндров.

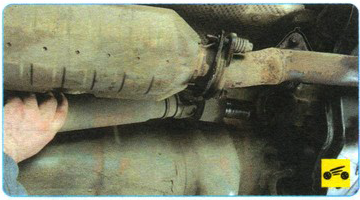

Причину недостаточной компрессии можно выяснить также подачей сжатого воздуха в цилиндр, в котором поршень предварительно установлен в ВМТ такта сжатия. Для этого снимите с компрессометра наконечник и присоедините к нему шланг компрессора. Вставьте наконечник в свечное отверстие и подайте в цилиндр воздух под давлением 0,2-0,3 МПа. Для того чтобы коленчатый вал двигателя не провернулся, включите высшую передачу и затормозите автомобиль стояночным тормозом. Выход (утечка) воздуха через дроссельный узел свидетельствует о негерметичности впускного клапана, а через глушитель о негерметичности выпускного клапана. При повреждении прокладки головки блока цилиндров воздух будет выходить через горловину расширительного бачка в виде пузырей.

14. После проверки компрессии установите все снятые детали в обратном порядке.

В статье не хватает:

- Фото инструмента

Источник: carpedia.club

![1 generation [2003 - 2007]](/uploads/Mitsubishi_Outlander_I_2003_-_2008_.jpg)

![3 generation [2012 - 2014]](/uploads/3.png)

![XL [2005 - 2012]](/uploads/4d137205da66f_.jpg)